Preparation method and device for refractory rare metal annular target materials

A rare metal and preparation device technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as cumbersome process routes, poor product compactness, and low product purity, and achieve simplified process routes and production Simple process and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

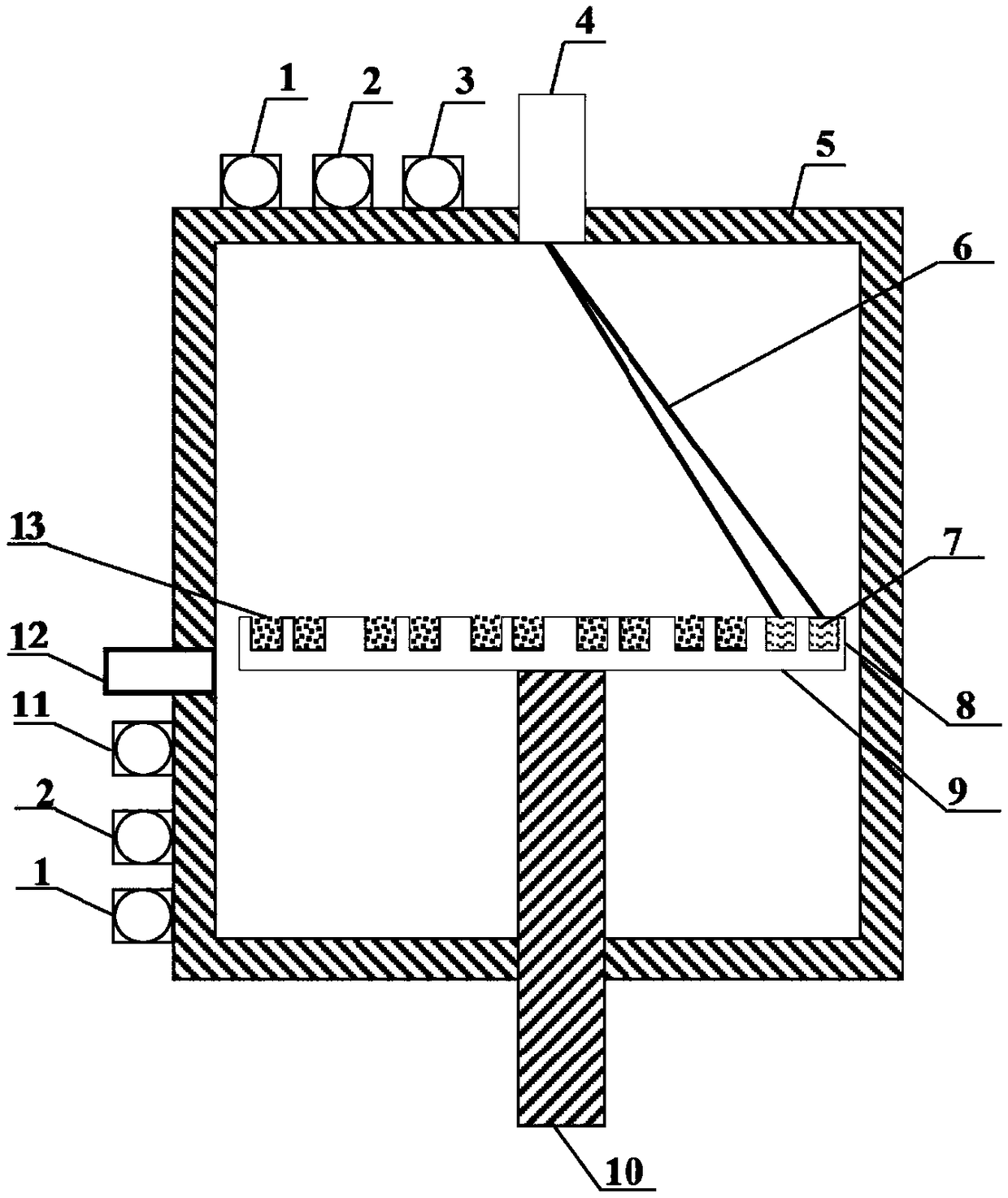

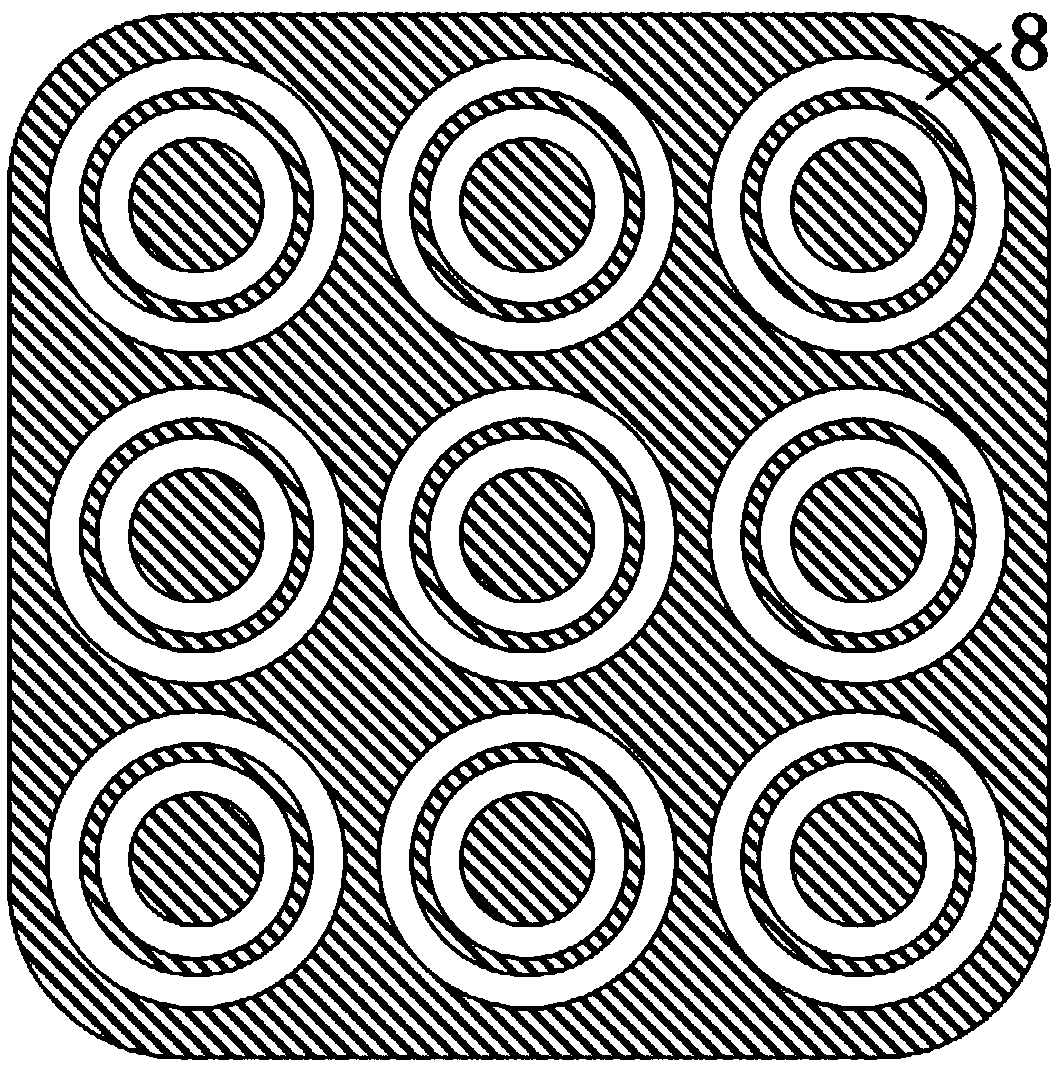

[0034] Such as figure 1 As shown, the preparation device of the refractory rare metal annular target according to the present invention includes a furnace body 5, a vacuum system, an air filling valve 12, an electron gun 4 and a water-cooled mold, and the furnace body is divided into a furnace chamber and an electron gun chamber, The vacuum system is respectively connected with the furnace chamber and the electron gun chamber, and the gas charging valve is respectively connected with the furnace chamber and the electron gun chamber. The water-cooled mold is arranged on the support seat 10 inside the furnace chamber, and the electron gun is arranged above the water-cooled mould. The water-cooled mold 9 is The mold that is provided with several annular water-cooling grooves 8. Such as figure 2 As shown, several annular water-cooling grooves are evenly distributed on the water-cooling mold. The depth of the annular water cooling groove is 30mm.

[0035] The vacuum system incl...

Embodiment 2

[0037] The preparation method of the refractory rare metal annular target according to the present invention comprises the following steps:

[0038] A. Loading: 500g of refractory rare metal raw materials 13 with an impurity element content of 0.5% are sequentially loaded into the water-cooling tank of the water-cooling mold;

[0039] B. Vacuuming: Close the furnace body, pass in cooling circulating water, open the vacuum system, and carry out vacuuming treatment: start the mechanical pump of the vacuum system in the furnace chamber, and after the furnace chamber is vacuumed to below 1000Pa, start the Roots pump to turn the furnace After the chamber is vacuumed below 10Pa, start the diffusion pump to vacuum the furnace chamber below 0.05Pa; start the mechanical pump of the electron gun vacuum system to pump the vacuum of the electron gun chamber below 1000Pa, start the Roots pump to vacuum the electron gun chamber After reaching below 10Pa, start the molecular pump to evacuate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com