An optimized forging process for gh6783 alloy bar

An alloy bar and process technology, applied in the field of metal forging technology, can solve the problems of uneven distribution of β phase, forging cracks, poor forging plasticity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

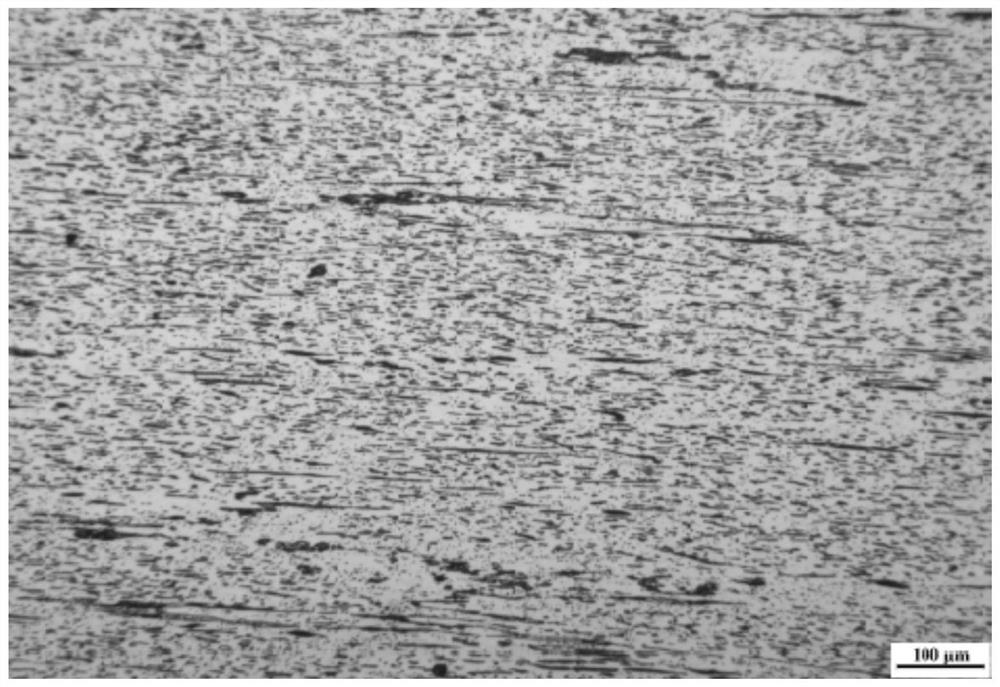

Embodiment 1

[0021]GH6783 alloy bar, specification φ200mm.

[0022]The steel ingot produced by a double vacuum process is φ406mm, the actual heating temperature is 1110 ° C, and it is produced after 2 h.

[0023]First fire forging: first fire, heating temperature 1110 ° C, forging single hammer compression amount of 50 mm, forged to 300 mm, back furnace, deformation amount of 30.5%.

[0024]Mid-fire forging: second fire, heating temperature 1080 ° C, forged single hammer compression amount of 40 mm, forged to φ280 mm, back furnace, deformation amount of 31.6%.

[0025]The third fire, the heating temperature is 1060 ° C, the amount of the upset, the amount of the upset deformation is 30%.

[0026]The fourth fire, the heating temperature is 1050 ° C, unute, a single hammer is 40 mm, forged to φ270 mm, and the deformation is 29%.

[0027]The fifth fire, the heating temperature is 1050 ° C, the upset, the amount of the upset deformation is 35%.

[0028]The sixth fire, the heating temperature is 1040 ° C, unute, a single...

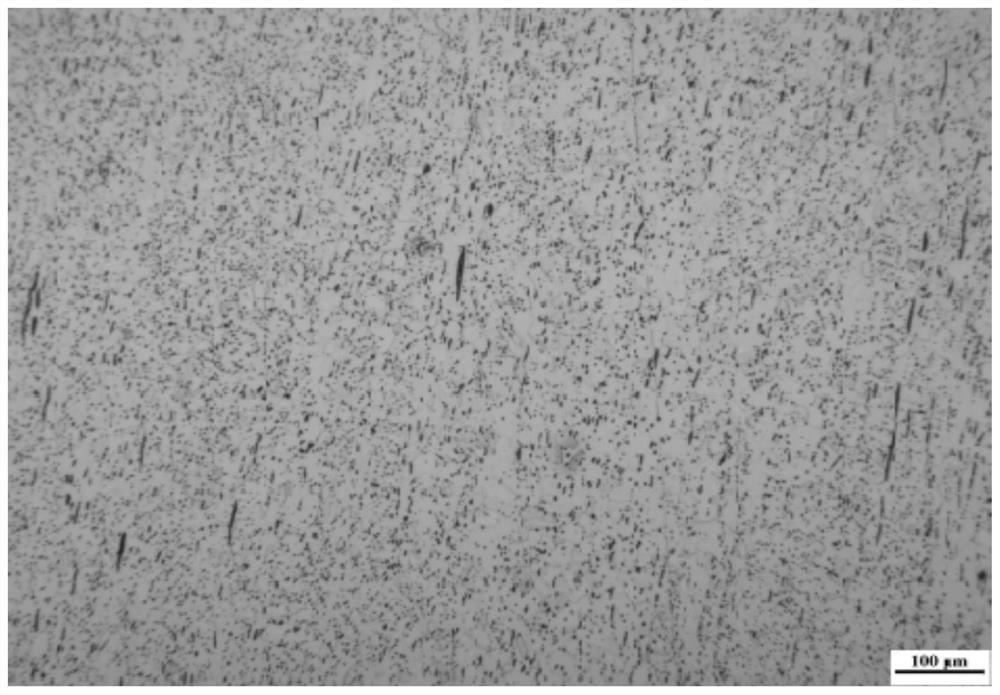

Embodiment 2

[0032]GH6783 alloy bar, specification φ200mm.

[0033]The steel ingot produced by a double vacuum process is φ406mm, the actual heating temperature is 1090 ° C, and it is produced after 2 h.

[0034]First fire forging: the first fire, heating temperature 1090 ° C, forging single hammer compression is 50mm, forged to 300 mm square, back furnace, deformation amount of 30.5%.

[0035]Mid-fire forging: second fire, heating temperature 1060 ° C, forged single hammer pressure below 40 mm, forged to φ280 mm, back furnace, deformation amount of 31.6%.

[0036]The third fire, the heating temperature is 1050 ° C, the amount of upset, the amount of the upset deformation is 30%.

[0037]The fourth fire, the heating temperature is 1050 ° C, unute, a single hammer is 40mm, forged to 220 mm, and the deformation is 38.5%.

[0038]Last fire forging: the fifth fire, heating temperature 1000 ° C, unute, single hammer pressure below 40 mm, forged from 220 mm to φ200mm bar, 35.1%.

[0039]Bar test: GH783 alloy bar has good ...

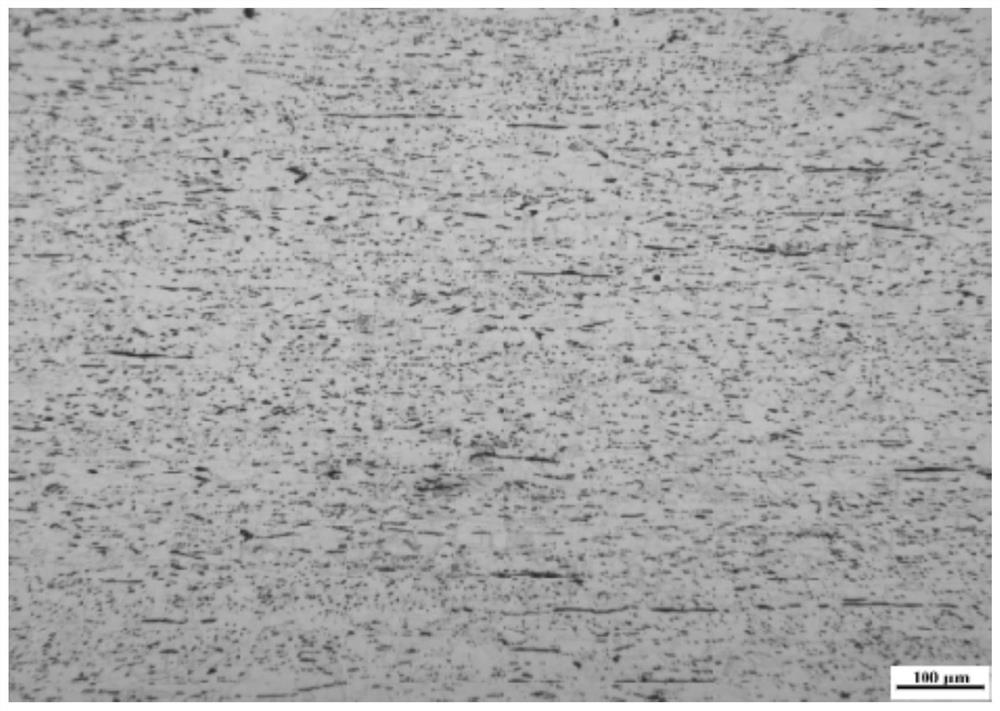

Embodiment 3

[0041]GH6783 alloy bar, specification φ200mm.

[0042]The steel ingots produced by the double vacuum process, the size is φ406mm, the actual heating temperature is 1100 ° C, and the heat is produced after 2 hours.

[0043]First fire forging: first fire, heating temperature 1100 ° C, forging single hammer pressure below 50 mm, forged to φ315 mm, back furnace, deformation amount of 39.8%.

[0044]Middle fire forging: second fire, heating temperature 1080 ° C, upsetting, upsetting 30%.

[0045]The third fire, the heating temperature is 1040 ° C, unute, a single hammer is 40 mm, forged to φ280 mm, and the deformation amount is 40%.

[0046]The fourth fire, the heating temperature is 1040 ° C, the amount of upset, the upset deformation is 35%.

[0047]The fifth fire, the heating temperature is 1030 ° C, unute, a single hammer is 40 mm, forged to φ270 mm, and the deformation amount is 30%.

[0048]Last fire forging: sixth fire, heating temperature 990 ° C, unute, single hammer is 40mm, from φ270 mm forged to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com