A wear-resistant screw of a twin-screw extruder and its processing technology

A twin-screw extruder and machining technology, applied in metal material coating process, coating, melt spraying, etc., can solve the problems of screw failure, screw component wear, high cost of screw, etc., to achieve tight combination and fixation , Improve the wear resistance, and the effect of low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

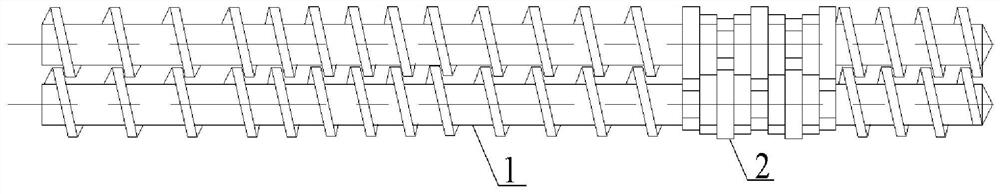

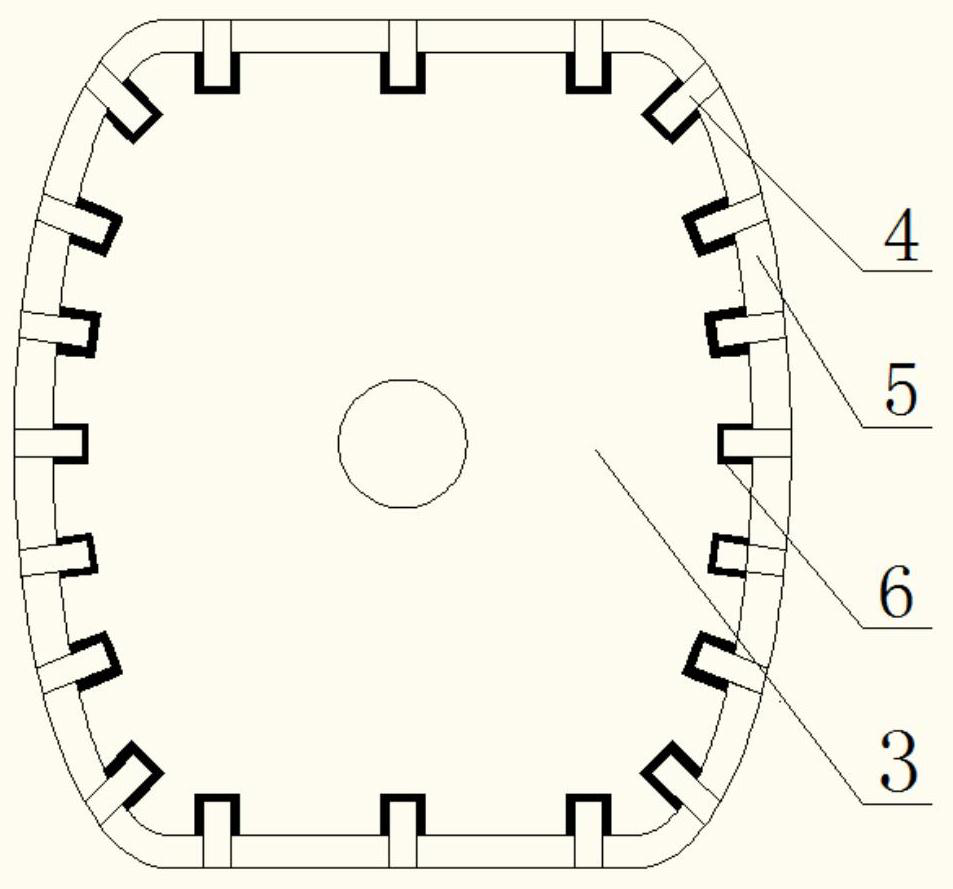

[0026] see figure 1 and figure 2 According to the wear-resistant screw of a twin-screw extruder provided by the present invention, the main technical scheme adopted is: the kneading block 2 of the screw 1 includes a steel substrate 3, a silicon nitride ceramic rod 4 and an alloy coating 5. Dimples 6 are evenly distributed on the outer surface of the steel base 3 parallel to the axial direction of the screw 1, half of the silicon nitride ceramic rod 4 in the length direction is in the dimples 6, so The other half of the silicon nitride ceramic rod 4 in the length direction is exposed outside the surface of the substrate 3, the alloy coating 5 covers the entire surface of the substrate 3, and the top end of the silicon nitride ceramic rod 4 is exposed Outside the alloy coating 5 . The wear resistance of the kneading block can be significantly improved by introducing silicon nitride ceramic components with extremely high hardness on the surface of the steel substrate 3, especi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com