Method for preparing chemical carbon powder by coagulation on basis of modified latex particles and modified pigment emulsion

A technology of latex particles and chemical carbon, applied in optics, electrical recording, instruments, etc., can solve problems such as poor dispersion and difficulty in washing and removing emulsifiers, achieve narrow particle size distribution, avoid resin redispersion process, simplify The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

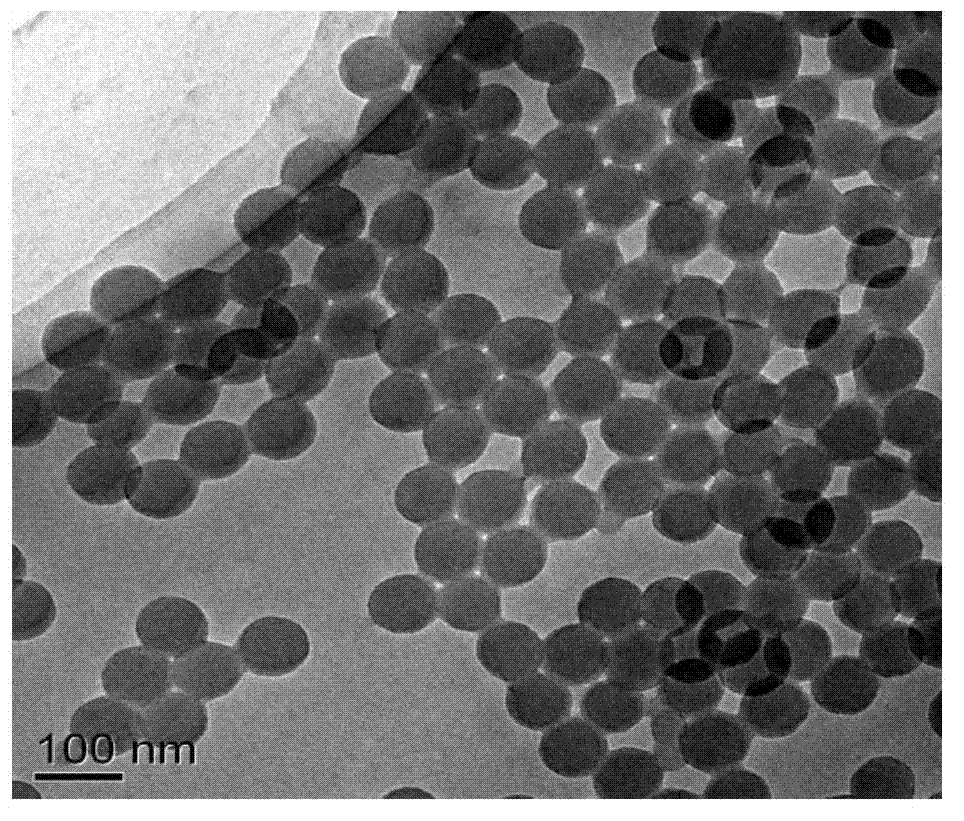

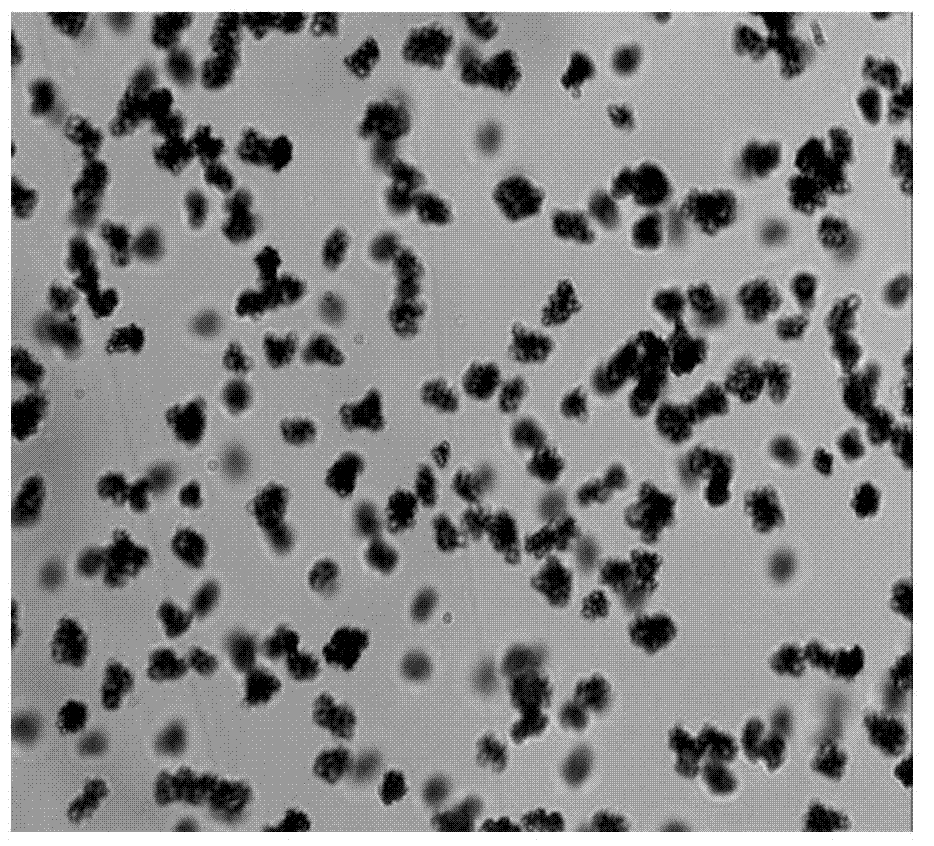

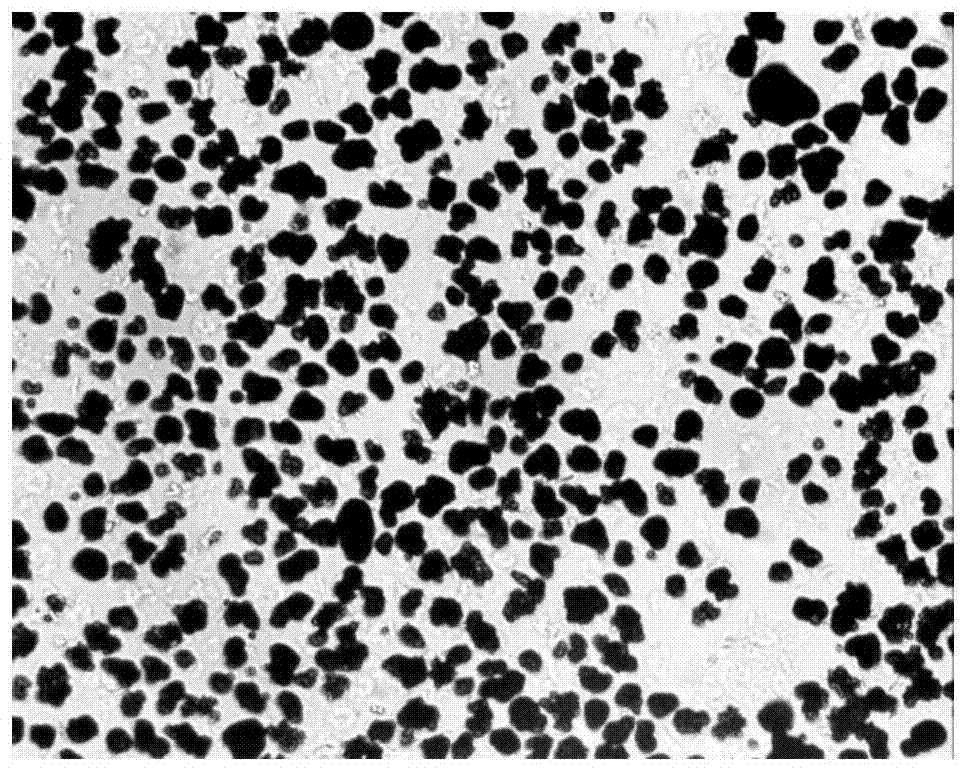

Image

Examples

Embodiment 1

[0035] Add 0.1 g of sodium dodecylbenzenesulfonate, 0.6 g of carnauba wax, and 20 g of deionized water into a beaker, and disperse the wax into an emulsion by ultrasonication for 10 minutes using an ultrasonic cell pulverizer. Add 0.1 g of sodium dodecylbenzenesulfonate, 0.2 g of P-15 type charge regulator produced by Hubei Dinglong, and 20 g of deionized water into a beaker, and disperse by ultrasonication for 10 minutes using an ultrasonic cell pulverizer. Add the above dispersion into a container equipped with an electric stirrer, condensed water, and a thermometer, then add 34g of surface sulfonated latex particle dispersion (resin glass transition temperature is 54°C, surface solid content 20%) and surface polymerization 1.2g of pigment particles coated with modified substances, 0.3g of polyvinyl alcohol, and 10g of water were mixed uniformly and the pH of the system was adjusted to about 2. The temperature of the reaction system is adjusted to 30°C, the stirring speed is...

Embodiment 2

[0037] Add 0.1 g of sodium dodecyl sulfonate, 0.6 g of carnauba wax, and 20 g of deionized water into a beaker, and disperse the wax into an emulsion by ultrasonication for 10 minutes using an ultrasonic cell pulverizer. Add 0.1 g of sodium dodecylbenzenesulfonate, 0.2 g of N-33 type charge regulator produced by Hubei Dinglong, and 20 g of deionized water into a beaker, and disperse by ultrasonication for 10 minutes using an ultrasonic cell pulverizer. Add the above dispersion into a container equipped with an electric stirrer, condensed water, and a thermometer, then add 34g of surface sulfonated latex particle dispersion (resin glass transition temperature is 60°C, surface solid content 20%) and surface polymerization Add 1.2g of modified pigment particles, 0.5g of Span-80, and 10g of water. After mixing evenly, adjust the pH of the system to about 2. The temperature of the reaction system was adjusted to 30°C, the stirring speed was adjusted to 400r / min, and 10g of coagulan...

Embodiment 3

[0039] Add 0.2 g of sodium lauryl sulfate, 0.6 g of carnauba wax, and 20 g of deionized water into a beaker, and disperse the wax into an emulsion by ultrasonication for 10 minutes using an ultrasonic cell pulverizer. Add 0.1 g of sodium dodecylbenzenesulfonate, 0.2 g of P-15 type charge regulator produced by Hubei Dinglong, and 20 g of deionized water into a beaker, and disperse by ultrasonication for 10 minutes using an ultrasonic cell pulverizer. Add the above dispersion into a container equipped with an electric stirrer, condensed water, and a thermometer, then add 34g of surface sulfonated latex particle dispersion (resin glass transition temperature is 40°C, surface solid content 20%) and surface polymerization Add 1.4g of modified pigment particles, 0.5g of Tween-85, and 10g of water, and adjust the pH of the system to about 2 after mixing evenly. The temperature of the reaction system is adjusted to 30°C, the stirring speed is adjusted to 300r / min, and 10g of coagulant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com