Backlight module

A technology of backlight module and backlight unit, which is applied in the direction of light guide, optics, optical components, etc., can solve the problems of high processing difficulty, achieve the effect of small processing difficulty and avoid the production of large-sized light guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

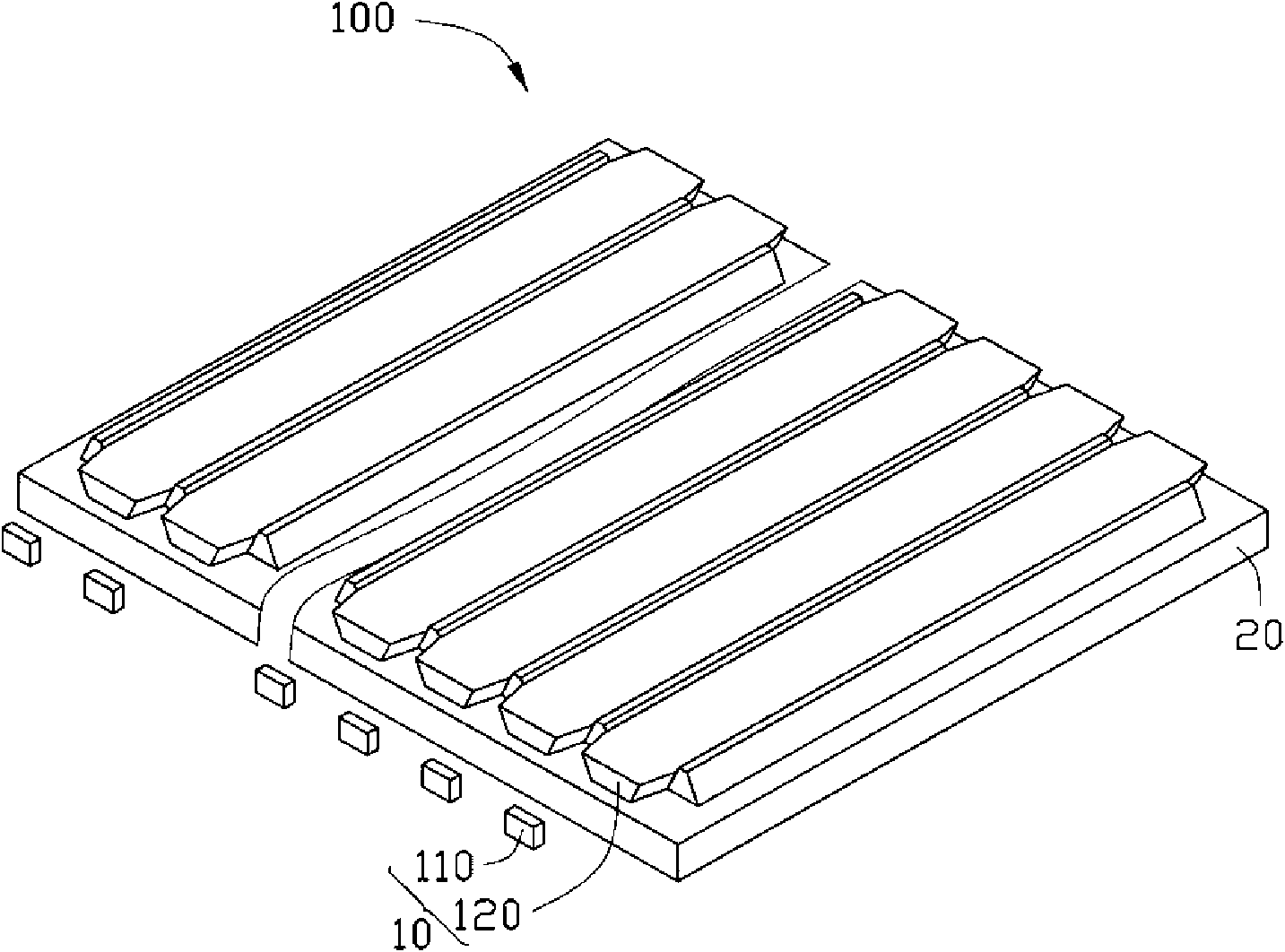

[0014] see figure 1 , the backlight module 100 provided by the present invention, the backlight module 100 includes a plurality of backlight units 10 and a frame 20 .

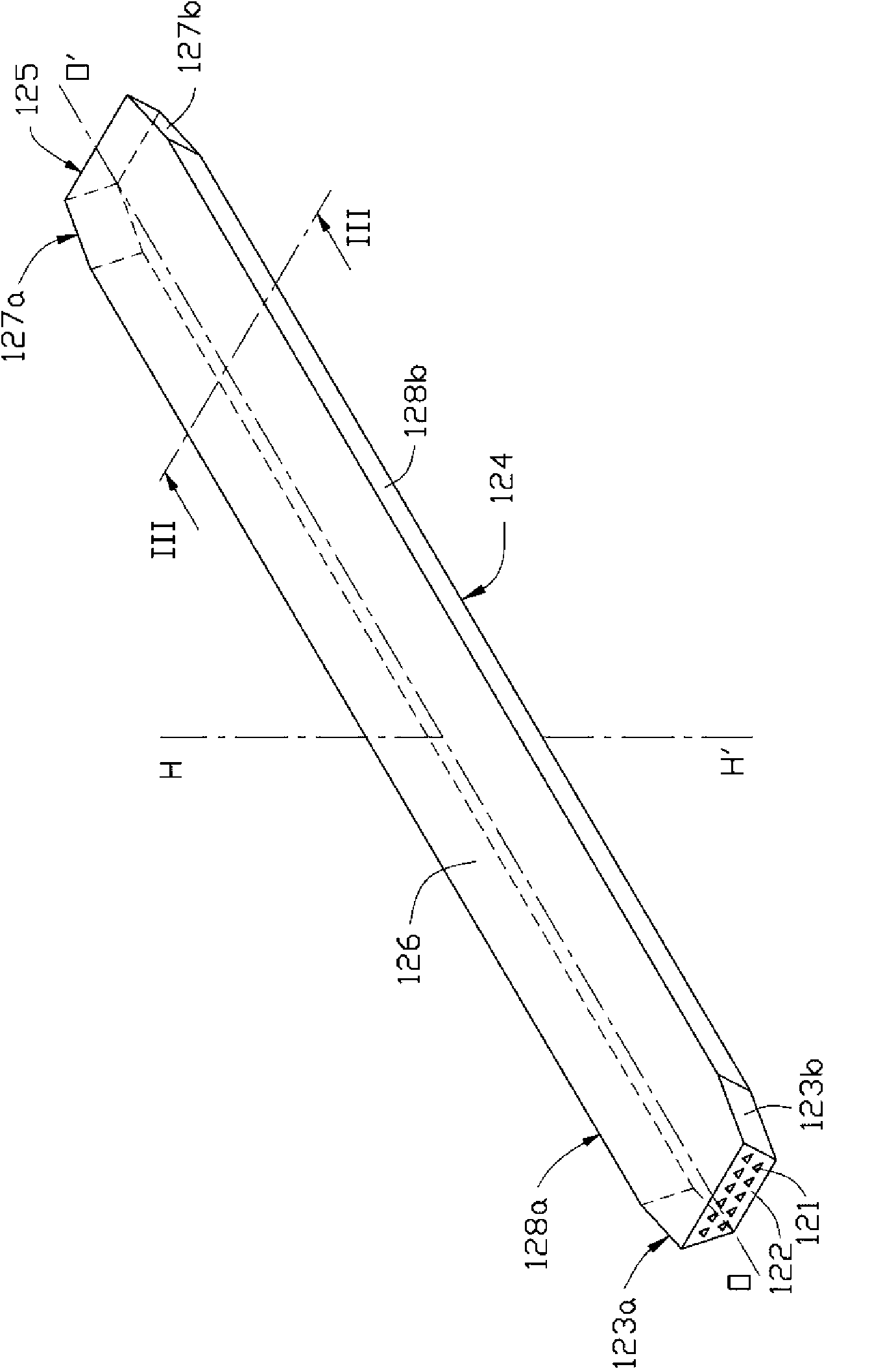

[0015] Each backlight unit 10 includes a light source 110 and a light guide plate 120 corresponding to the light source 110 . In this embodiment, the light sources 110 are light emitting diodes, and each light source 110 can be controlled to emit light of different colors according to an external color control signal. see figure 2 , the light guide plate 120 includes an incident surface 122 opposite to the light source, a bottom surface 124, an outgoing surface 126 opposite to the bottom surface 124, a first reflective surface 123a, a second reflective surface 123b, and a third reflective surface 125, a fourth reflective surface 127a, a fifth reflective surface 127b, a first side 128a, and a second side 128b opposite to the first side 128a.

[0016] The incident surface 122 is provided with a plurality of "...

no. 2 approach

[0024] see Figure 5 The difference between the backlight module (not shown) in this embodiment and the backlight module 100 in the first embodiment is that the light guide plate 130 includes an incident surface 132 opposite to the light source (not shown) and a bottom surface 134 , an outgoing surface 136 opposite to the bottom surface 134, a first reflective surface 133a, a second reflective surface 133b, a third reflective surface 135, a first side 138a and a second opposite to the first side 138a Side 138b. The third reflective surface 135 is located between the first side 138a and the second side 138b.

no. 3 approach

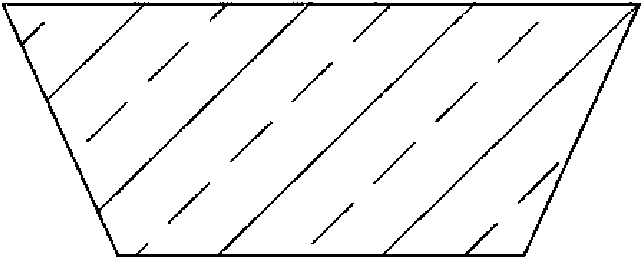

[0026] see Image 6 The difference between the backlight module (not shown) of this embodiment and the backlight module 100 of the first embodiment is that the first side 148a and the second side 148b of the light guide plate 140 are trapezoidal, that is, the light guide plate 140 It is a wedge-shaped light guide plate.

[0027] The backlight module provided by the present invention uses a plurality of light guide plates to be closely accommodated in a plurality of accommodation spaces on the frame to meet the requirements of a large-size backlight module for a large-size liquid crystal display, and at the same time avoids using a large mold or a large molding machine for large-scale The light guide plate is manufactured, and the subsequent processing is less difficult.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com