Method and system for jointly and circularly generating electricity by gasifying municipal garbage at high temperature

A gasification combined cycle, municipal waste technology, applied in the field of energy-saving and environmental protection treatment of municipal waste, can solve the problems of high waste resource utilization and secondary pollution, and achieve the effect of high resource utilization and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of method of utilizing urban refuse high-temperature gasification combined cycle power generation described in the present invention, it comprises the following steps:

[0034] (a) Dry and crush a large amount of stored garbage; when drying, superheated steam is used as the drying medium, and the drying temperature is about 200°C to evaporate the water in the garbage; when crushing, the crushing fineness of the garbage should be below 1mm;

[0035] (b) Then burn the garbage obtained in step (a) under pure oxygen environment, the combustion temperature is at 1000~1250°C (such as at 1000°C, 1100°C or 1250°C), and the pressure in the combustion chamber is at a slight positive pressure~4MPa (such as micro Positive pressure, 1MPa or 4MPa), the organic components in the garbage are gasified into synthesis gas, and the inorganic components are melted into slag;

[0036] Rapidly cool the synthesis gas and slag obtained from combustion to a temperature below 120°C, then d...

Embodiment 2

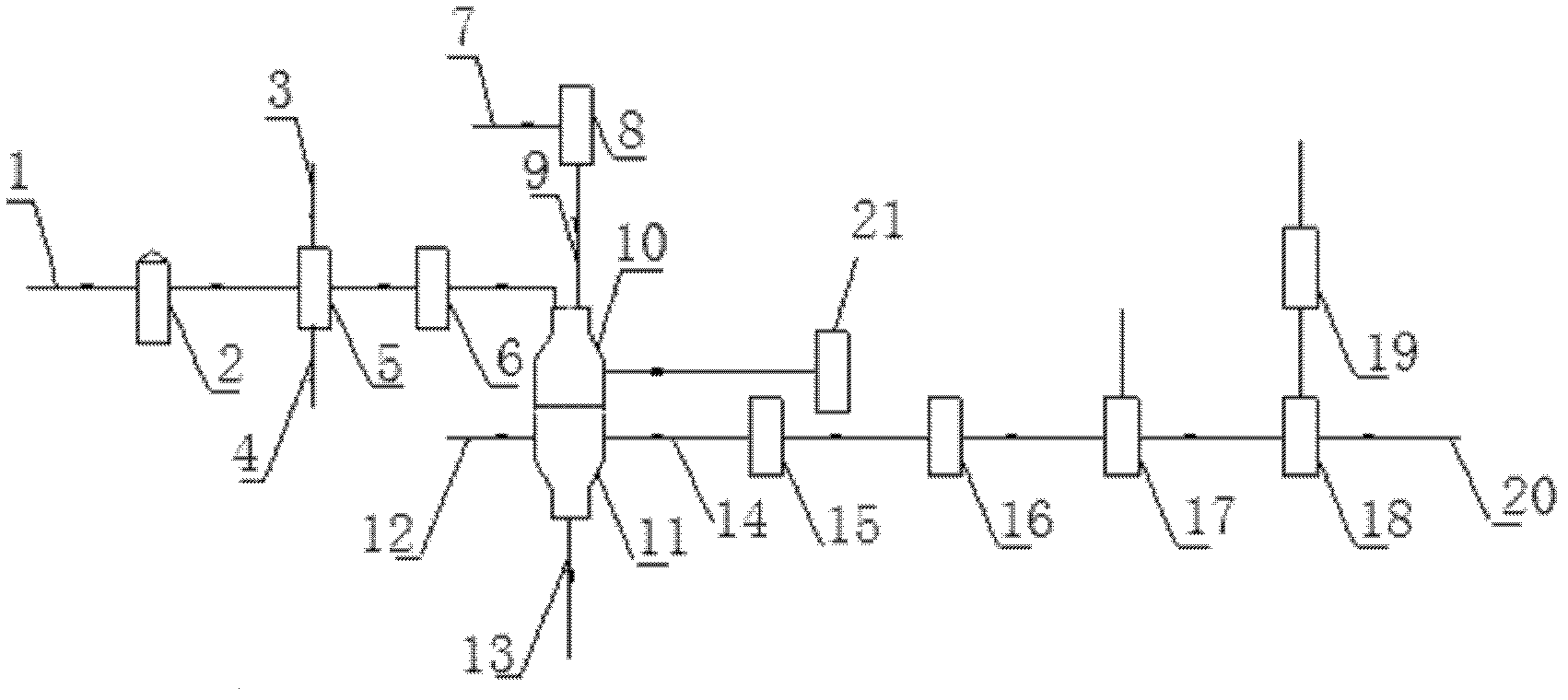

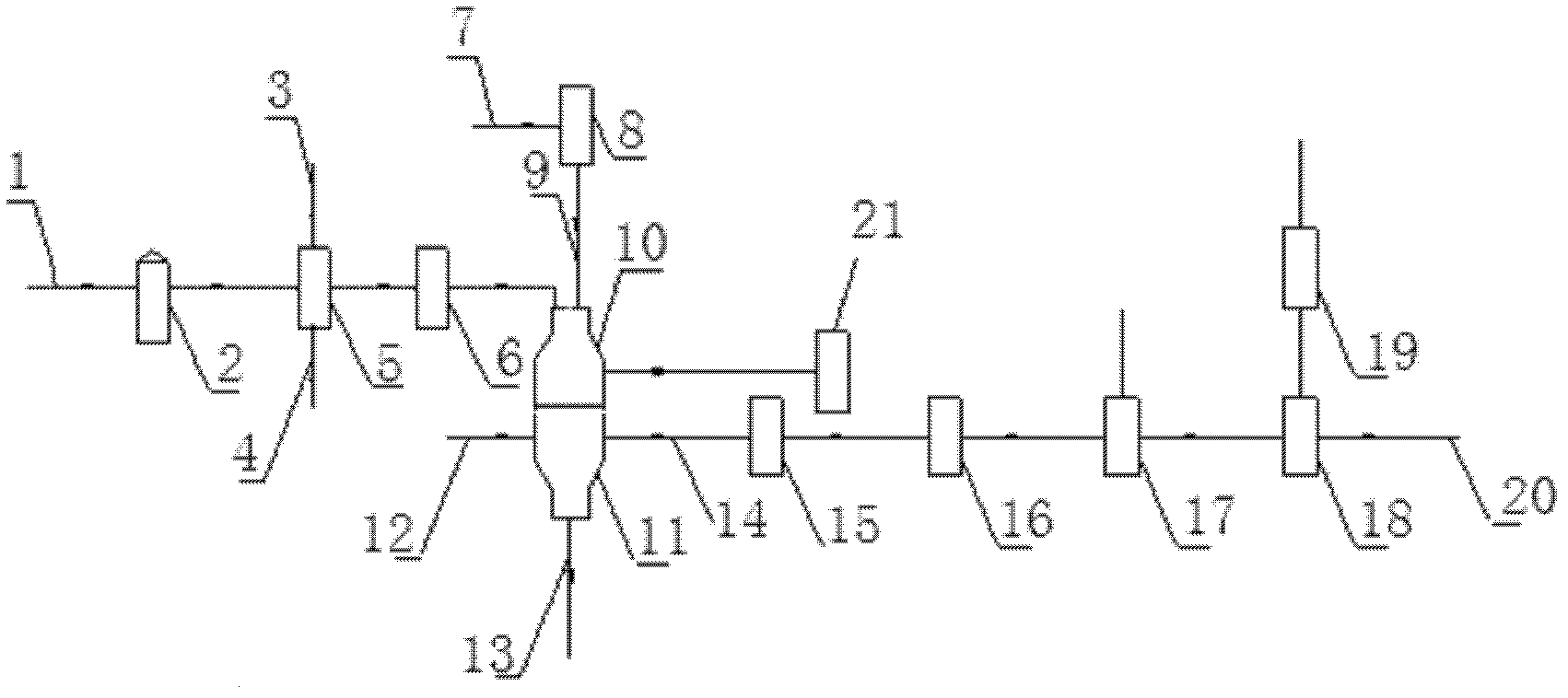

[0040] like figure 1 Shown, a kind of method of utilizing municipal refuse high-temperature gasification combined cycle power generation described in the present invention, it comprises following specific steps:

[0041] (a) Garbage is stored in the garbage storage bin 2, and then the garbage is transported to the drying device 5, and the superheated steam is transported to the drying device 5 through the superheated steam inlet pipeline 3, and the garbage is dried and then output through the saturated steam output pipeline 4; drying The final rubbish is transported to the crushing device 6 and crushed to a fineness below 1mm;

[0042] (b) The air is separated from the oxygen by the air separation unit 8, and the oxygen is transported to the upper gasification section 10 of the incinerator gasification furnace through the oxygen delivery pipeline 9; The gasification section 10 is combusted with oxygen; the combustion temperature is 1000-1250°C (for example, at 1000°C, 1100°C ...

Embodiment 3

[0050] like figure 1 As shown in the present invention, a system for generating electricity using high-temperature gasification combined cycle of urban waste, which includes sequentially connected waste storage and conveying unit, drying unit, crushing unit, air separation unit, gasification unit, washing unit, Flue gas purification unit and gas-steam combined cycle power generation unit;

[0051] The garbage storage and delivery unit includes a garbage delivery pipeline 1, and the entrance of the garbage storage bin 2 is connected to the garbage delivery pipeline 1; garbage enters the garbage storage bin 2 through the garbage delivery pipeline 1;

[0052] The drying unit includes a drying device 5, the inlet of the drying device 5 is connected to the outlet of the garbage storage bin 2 through a pipeline, and the superheated steam intake pipeline 3 and the saturated steam output pipeline 4 are connected to the inlet and the outlet of the drying device 5 respectively. Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com