Blast furnace slag waste heat recycling system

A waste heat recovery and blast furnace slag technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of destroying the industrial chain, changing slag, and slag flushing steam not being used, so as to improve the economic benefits of enterprises and reduce water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

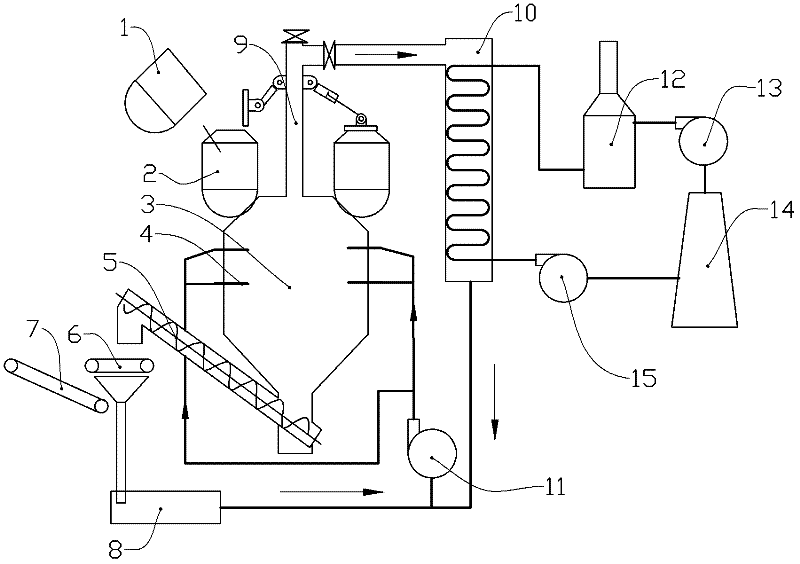

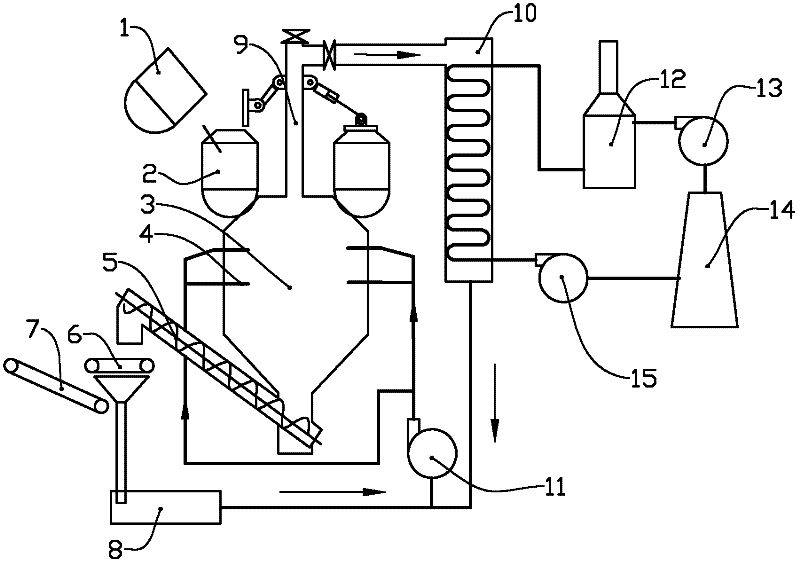

[0014] Such as figure 1 , a blast furnace slag waste heat recycling system, comprising a liquid slag transport tank 1, a liquid slag fixing tank 2, a sealed slag flushing tank 3, a slag flushing water nozzle 4, a spiral slag discharge device 5, a water slag dehydration device 6, a water slag Conveyor belt 7, slag flushing water sedimentation tank 8, slag flushing steam discharge pipe 9, partition wall heat exchanger 10, slag flushing water pump 11, evaporation boiler 12, generator 13, steam condenser 14, power generation water circulation pump 15 and compressed air Supplementary pressure device.

[0015] The sealed slag tank 3 is a sealed tank body, liquid slag flows into the sealed slag tank 3 through the liquid slag fixing tank 2, and the slag and water spray realize the purpose of generating steam, so the sealed slag tank 3 is the place where steam is generated. The sealed slag tank 3 has a liquid slag inflow port and a steam discharge pipe connected with the liquid slag f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com