Treatment device of liquid slag

A processing device and liquid slag technology, applied in the direction of recycling technology, process efficiency improvement, etc., can solve the problems of not paying attention to slag particles, expensive inert gas, sticky slag, etc., to delay particle settling time and improve granulation efficiency , The effect of saving equipment and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

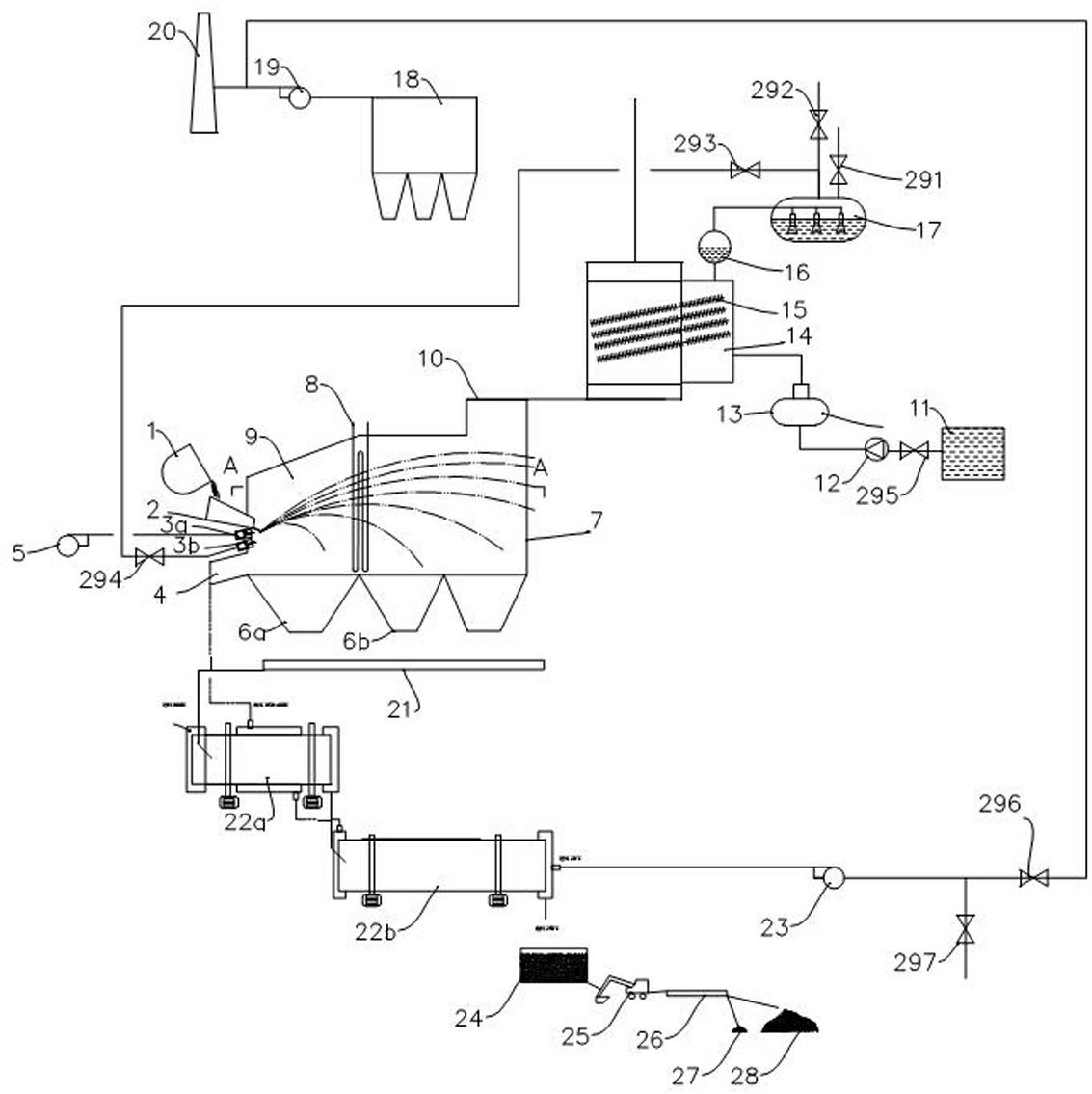

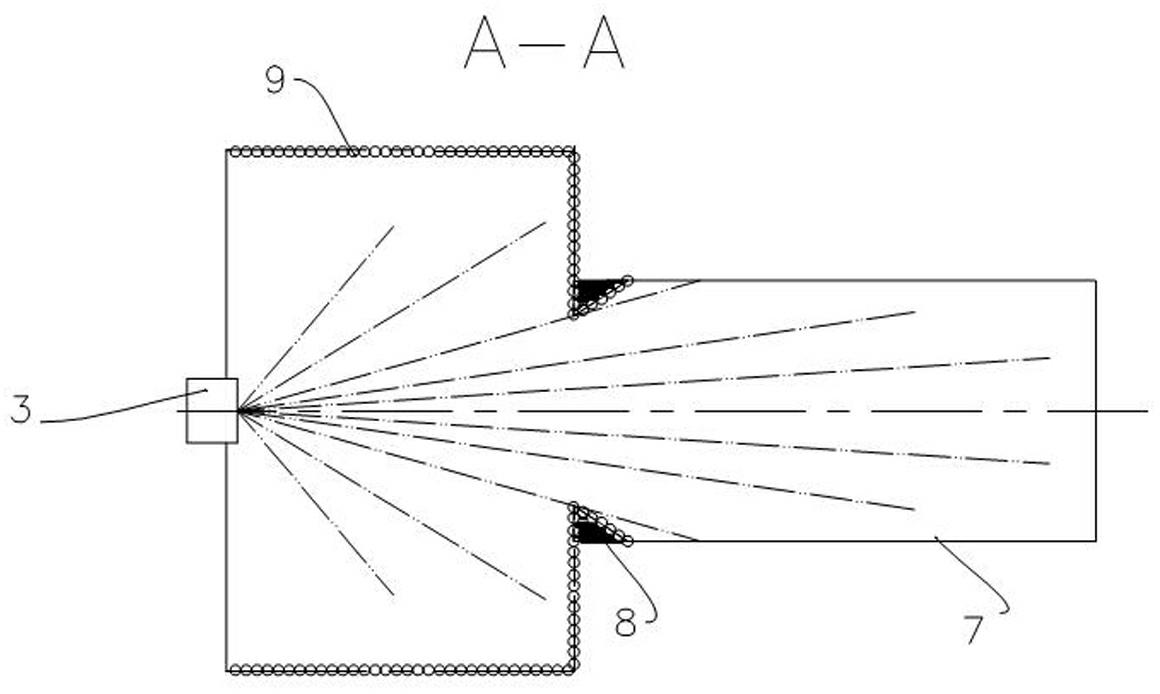

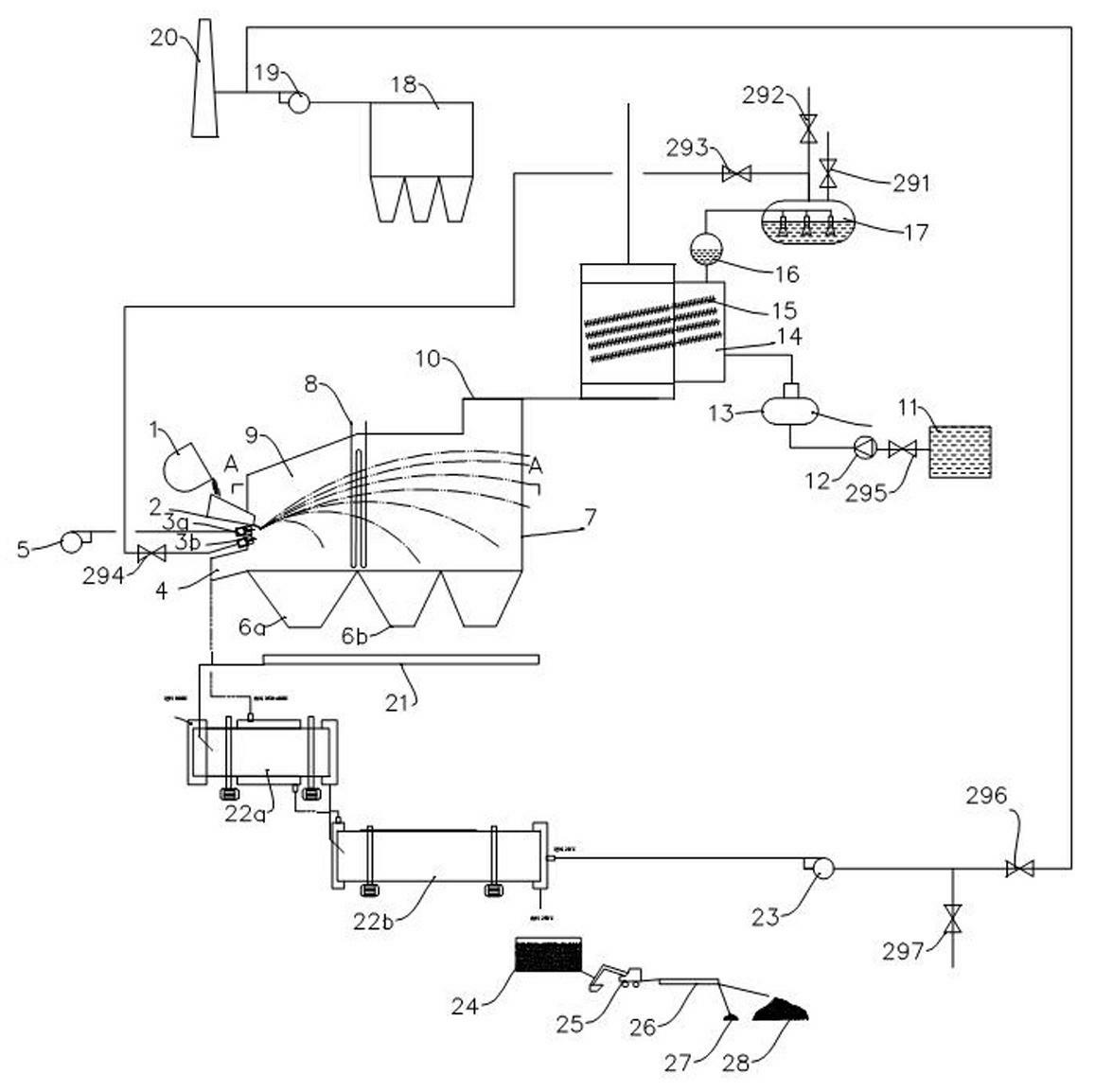

[0038] Such as figure 1 , figure 2 , the high-temperature liquid slag from the converter or electric furnace flows out from the slag bag 1 through the launder 2, and is granulated into large and small particles by the slag breaker 3. 5 receive, and the remaining smaller particles fly a long distance and then fall, and are received by the small particle ash hopper 6. The cold air used to cool the particles enters through the air inlet 4, and after exchanging the heat of the slag, it becomes hot air and is discharged from the air outlet 10, and then the waste heat is recovered.

[0039] The slag particles collected by the ash hopper 6 are transported to the buffer machine 22a and the cooling machine 22b through the ash conveyor 21 for heat exchange of the solid slag particles. The last lower temperature slag particles enter the shallow stuffy pool 24 for stabilization, then dig out through excavator 25, and magnetically select scrap iron and steel 27 through magnetic separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com