Microwave heating method and apparatus for iron oxide reduction

A technology of iron oxide and microwave radiation, which is applied in lighting and heating equipment, metal processing, sustainable manufacturing/processing, etc., can solve the problems of waste of carbon combustibles and increase of carbon "footprint", achieve easy continuous processing, avoid sulfur and The effect of phosphorus residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the Detailed Description section that follows, certain terminology will be used for clarity of presentation and specific embodiments will be described in accordance with 35 USC 112 . However, it should be understood that this should not limit, nor should it be a limit to various forms and changes of the present invention that may occur within the scope of the claims.

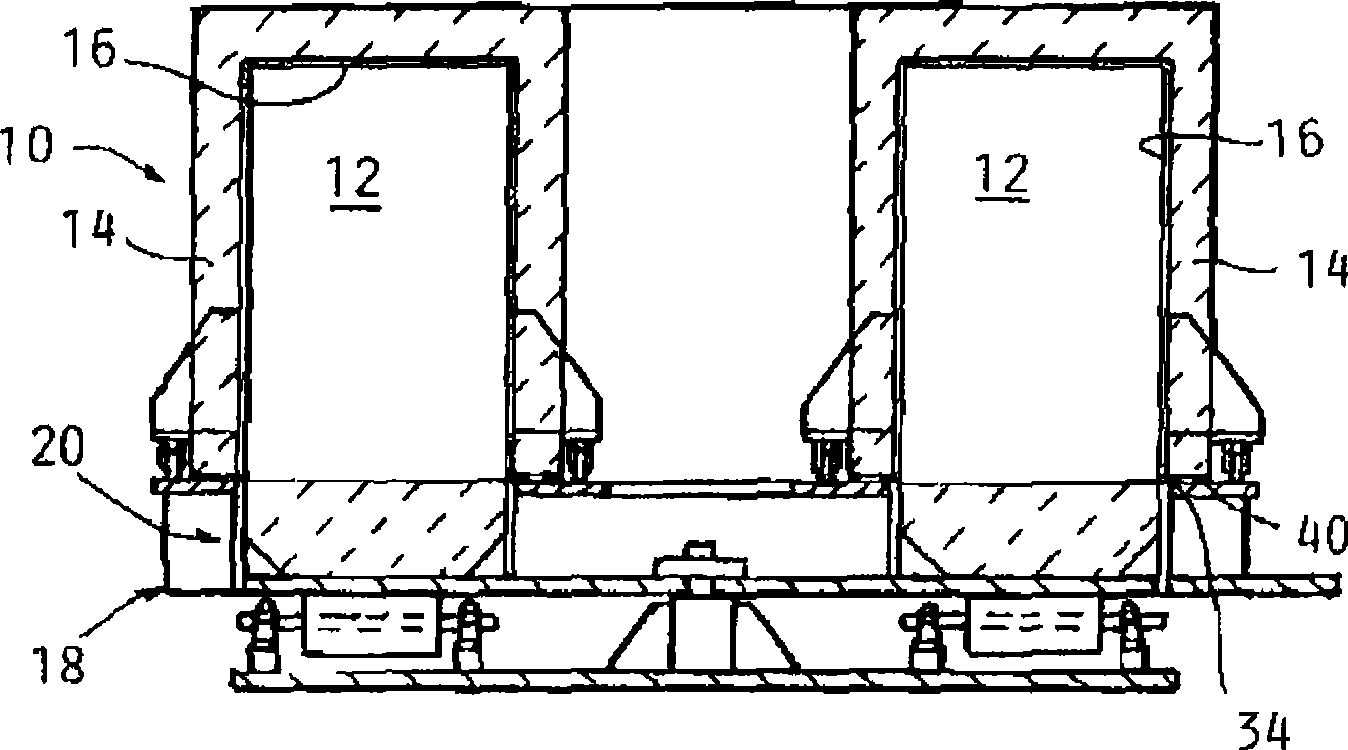

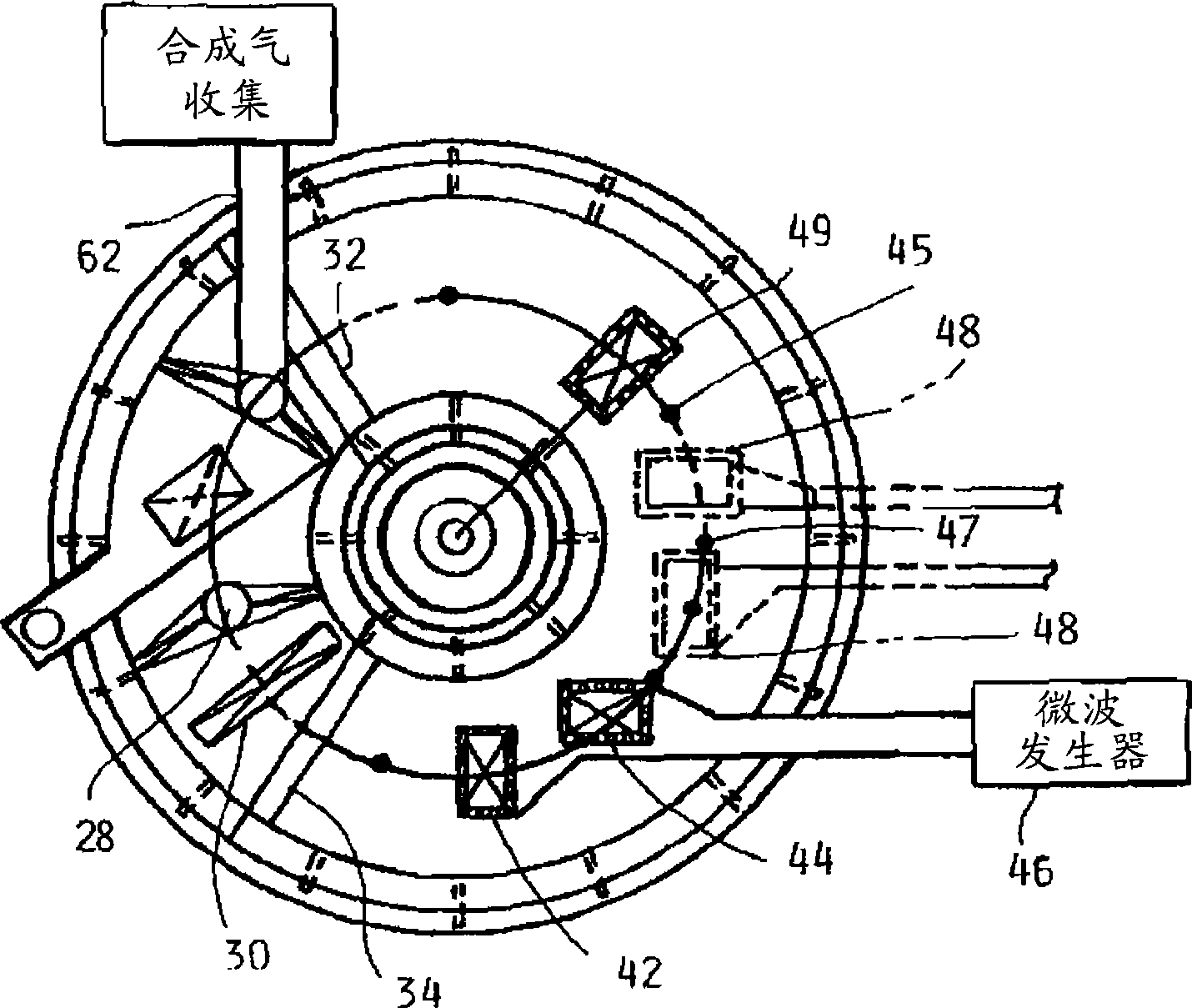

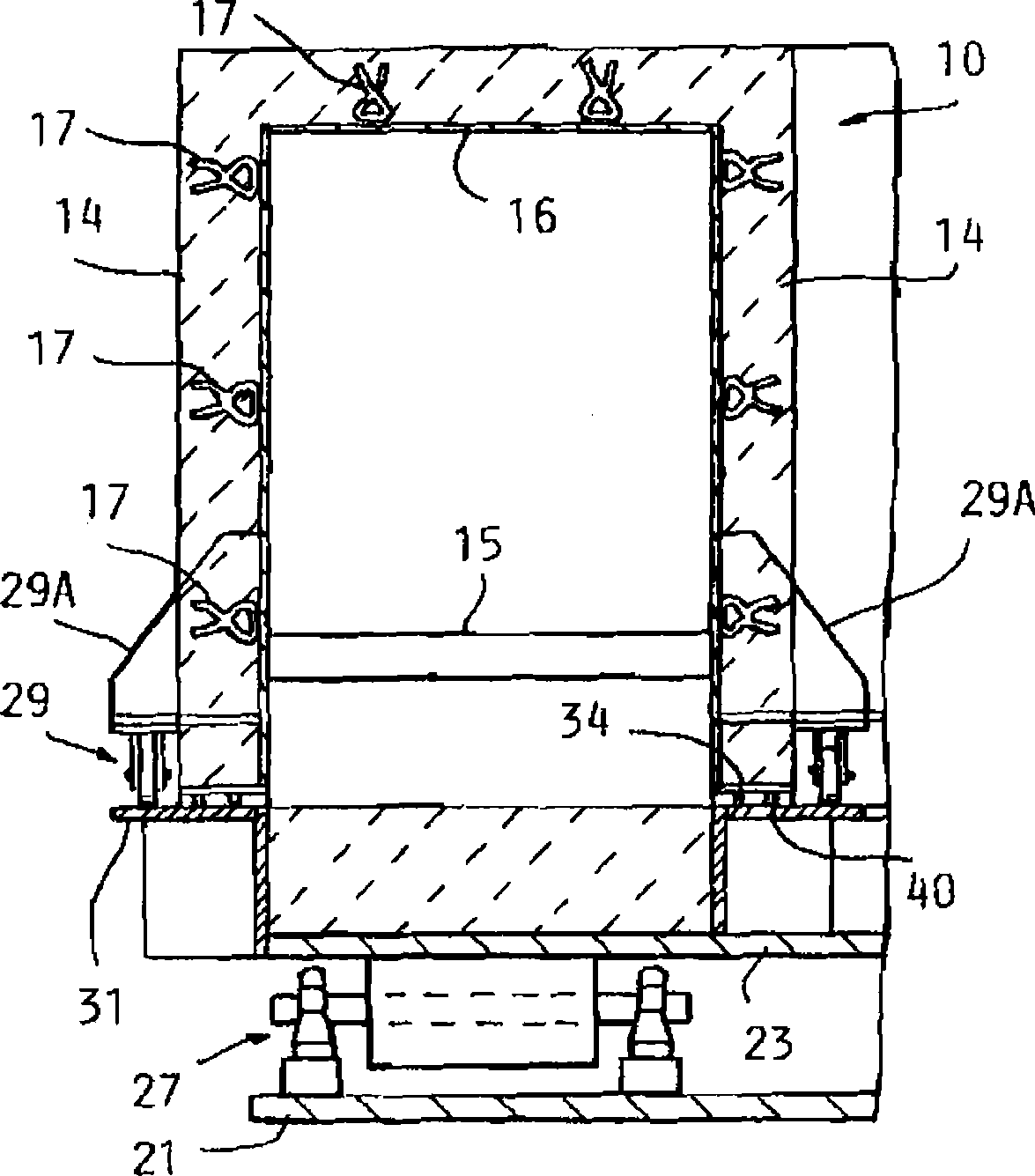

[0041] Referring to the accompanying drawings in particular Figure 1-5 , depicts a rotary hearth furnace 10 according to the present invention. The rotary hearth furnace comprises a fixed annular upper furnace chamber 12 having an inner wall 14 composed of refractory insulating material, a stainless steel inner skin 16 connected to built-in anchors 17 in the refractory wall 14 . An annular hearth 20 supported by a rotating base assembly 18 is rotatable beneath a stationary annular furnace chamber 12 by a motor-right-angle drive 24 and a chain 26 . Below the support plate 23 , a series of main roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com