High porosity metal biporous foam

a metal powder and high porosity technology, applied in the field of porous foams, can solve the problems of affecting the initial foam, so as to reduce the atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present method is an environmentally friendly process for making high porosity metal biporous foam using GRAS materials or their derivatives (which in the latter case may not all be GRAS members).

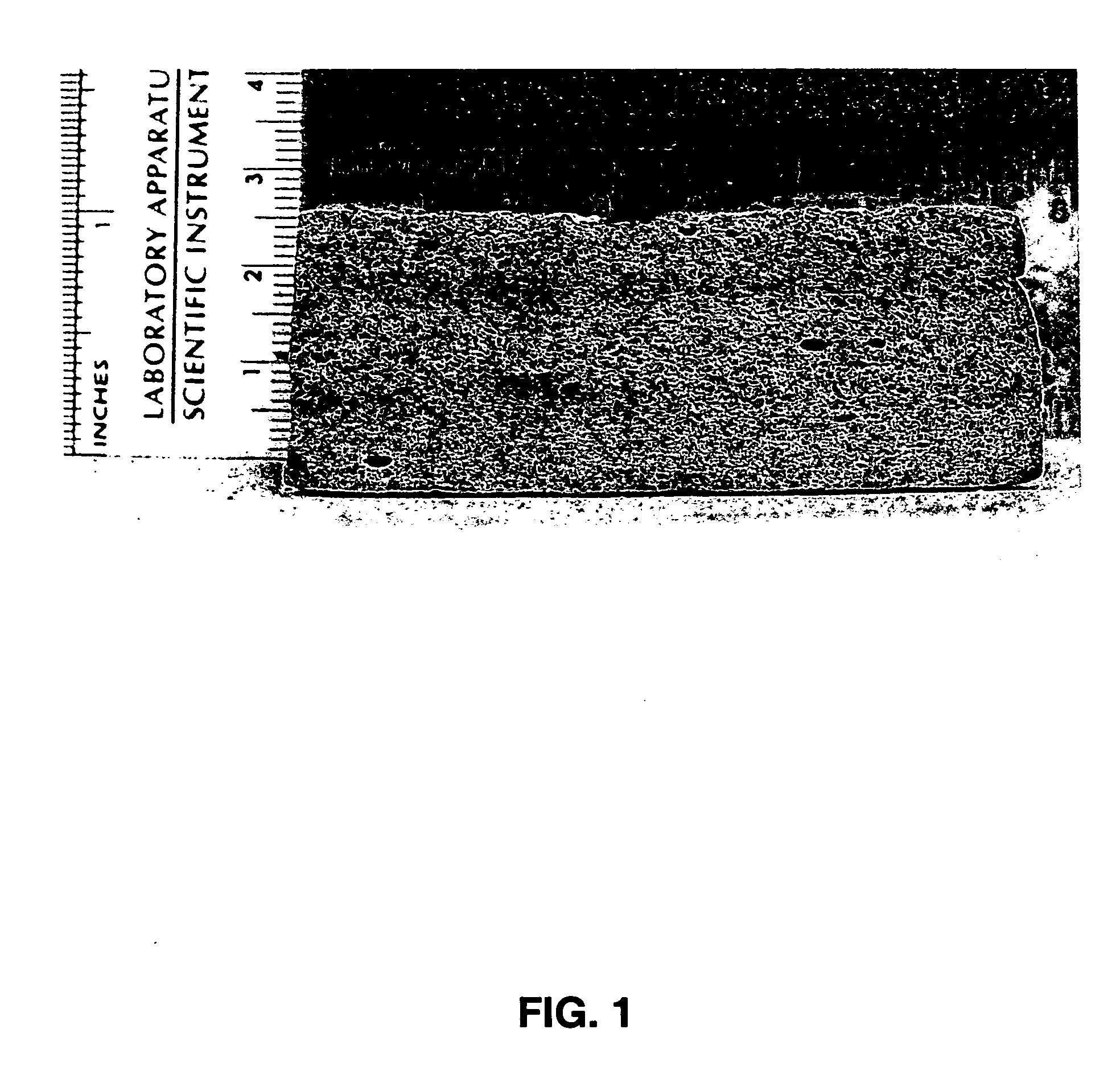

[0026] Using traditional methods and traditional atomized metal particles, commercially available struts have a porosity of about 10%-60% or a metal content only as low as 40%. In contrast, the present process of using filamentary carbonyl derived metal powders results in struts having about 85%-95% porosity or a metal density of about 5%-15%.

[0027] The term “about” before a series of values, unless otherwise indicated, shall apply to each value in the series.

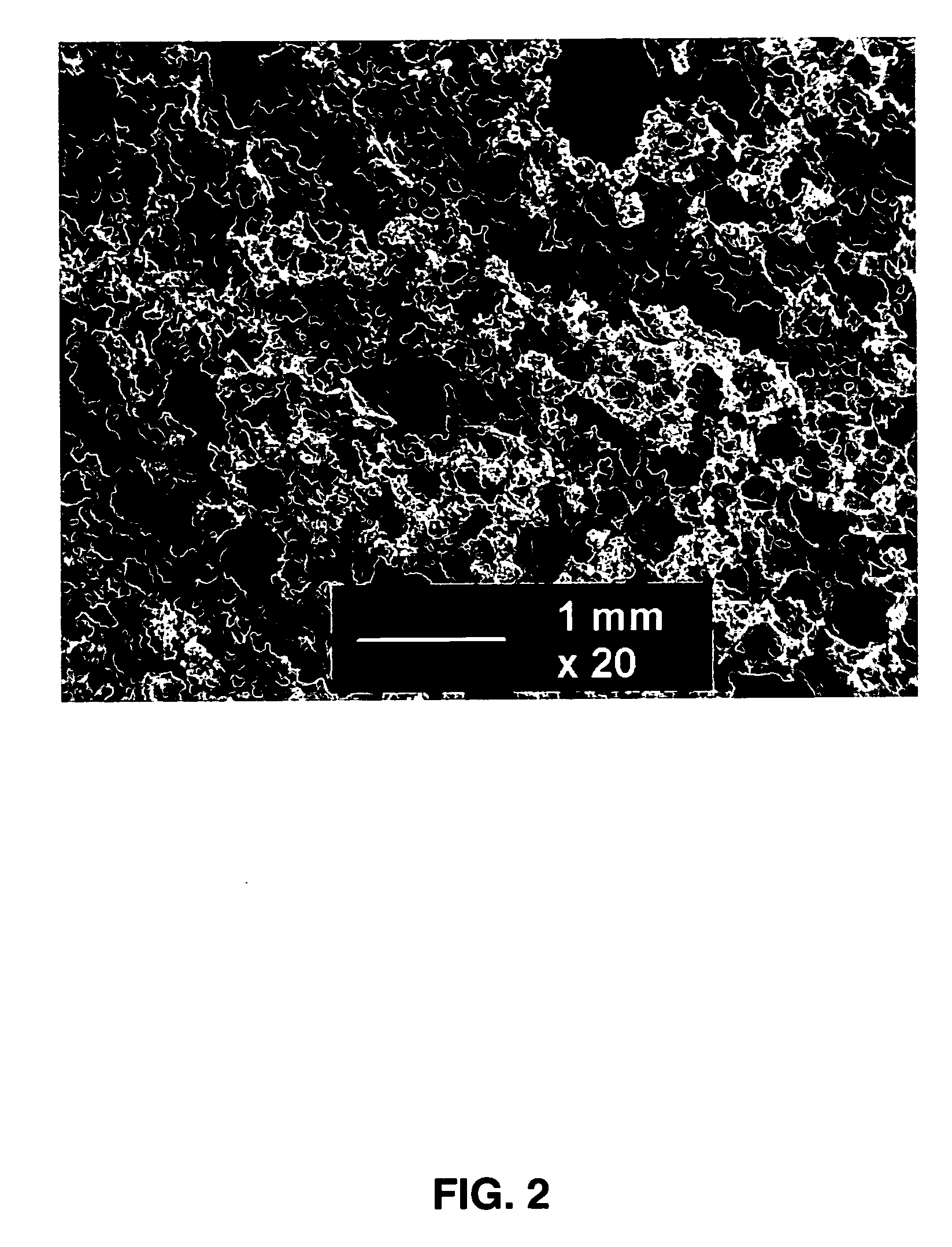

[0028] The term “filamentary” means, a characteristic three-dimensional chain-like network of fine or extra fine particles exhibited, for non-limiting example, by Inco® T255 nickel powder.

[0029] The assignee of the present invention (Inco Limited) produces and sells a series of ultra fine and exceedingly pure filamentary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com