Machining method of metal packaging shell of large-scale and large-power integrated circuit

An integrated circuit and metal packaging technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problem of not being able to reach industrial production, not fully satisfying the processing of large-scale high-power integrated circuit shells, and not fully satisfying the product environment Adaptability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

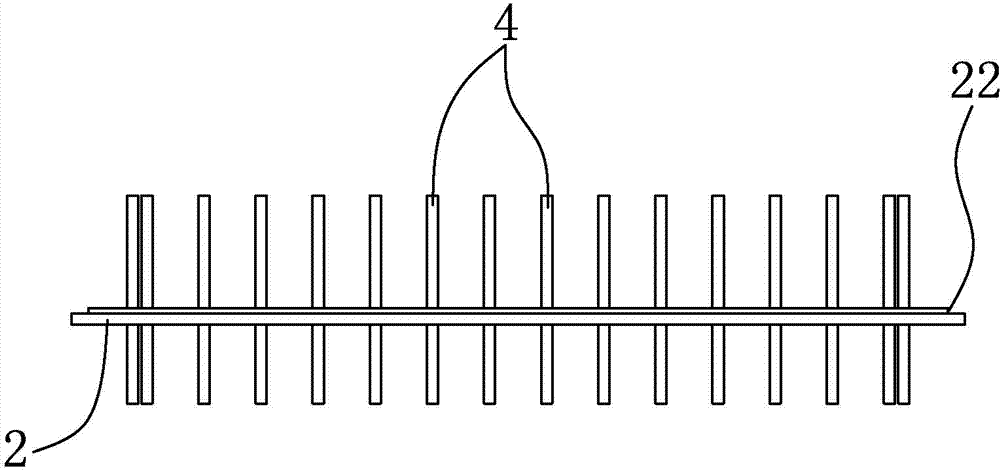

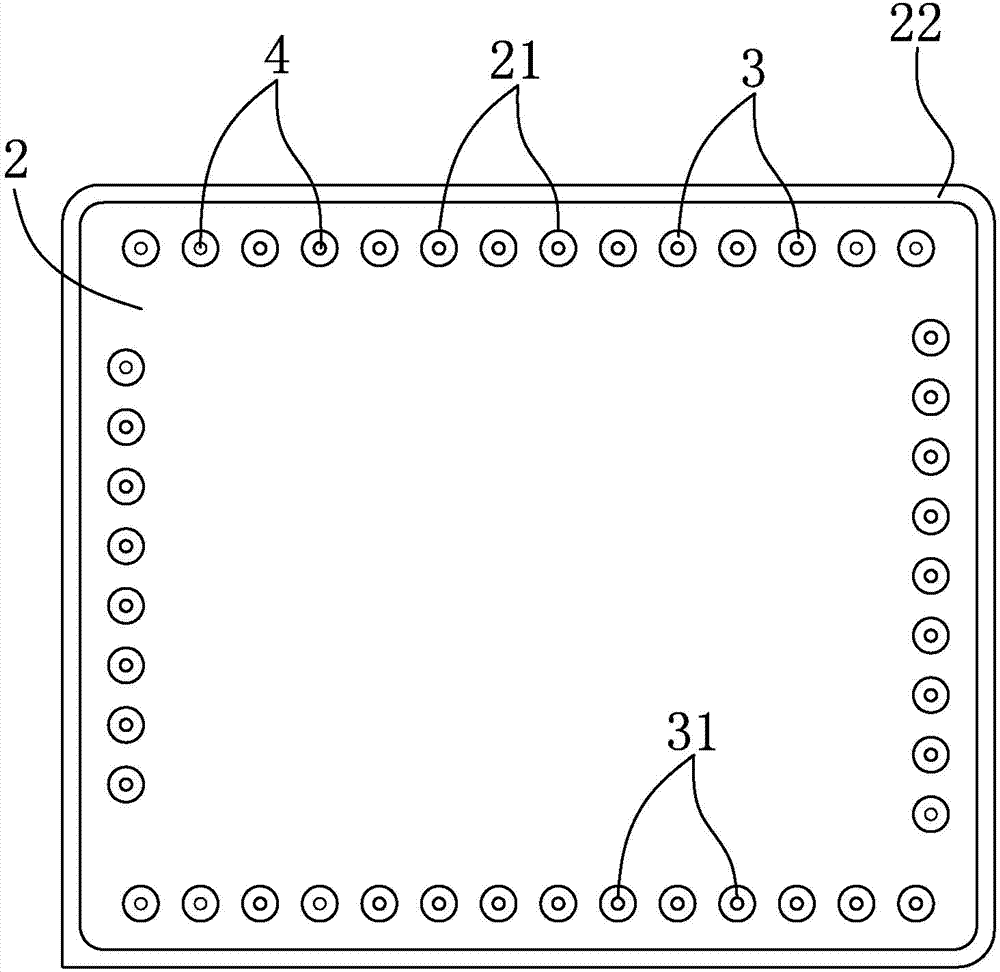

[0046] For the processing method of large-scale and high-power integrated circuit metal packaging shell, see figure 2 — Figure 5 , the shell includes a base and an outer cover 1, the base is composed of a base plate 2, forty-five glass blanks 3, and forty-five lead pins 4, and the base plate 2 is provided with forty-five pins for placing lead pins 4 and glass blanks. 3 through the first through hole 21, the lead pin 4 is placed in the first through hole 21 on the bottom plate 2 through the glass gob 3;

[0047] The processing method of the base includes the following process steps:

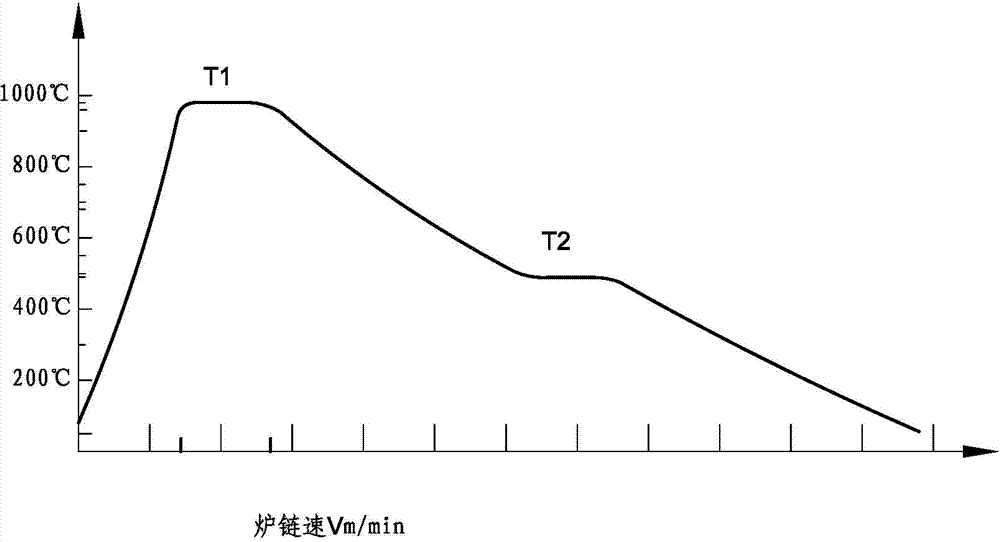

[0048] (1) Use the processing center LMC-1000 to process the Kovar alloy sheet material 4J29 into a rectangular bottom plate 2 with forty-five first through holes 21 for placing the lead pins 4 and the glass blank 3. The periphery of the bottom plate 2 is provided with Place the step 22 of the outer cover 1, after the machining is completed, sandblast the surface of the bottom plate 2, and then ...

Embodiment 2

[0057] For the processing method of large-scale and high-power integrated circuit metal packaging shell, see figure 2 — Figure 5 , the shell includes a base and an outer cover 1, the base is composed of a base plate 2, forty-five glass blanks 3, and forty-five lead pins 4, and the base plate 2 is provided with forty-five pins for placing lead pins 4 and glass blanks. 3 through the first through hole 21, the lead pin 4 is placed in the first through hole 21 on the bottom plate 2 through the glass gob 3;

[0058] The processing method of the base includes the following process steps:

[0059] (1) Use the processing center LMC-1000 to process the Kovar alloy sheet material 4J29 into a rectangular bottom plate 2 with forty-five first through holes 21 for placing the lead pins 4 and the glass blank 3. The periphery of the bottom plate 2 is provided with Place the step 22 of the outer cover 1, after the machining is completed, sandblast the surface of the bottom plate 2, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com