Electrolyte mixture, composition for conductive polymer synthesis and conductive polymer solid electrolytic capacitor formed by using the same

A conductive polymer and polymer technology, applied in solid electrolytic capacitors, capacitor parts, capacitor electrolytes/absorbers, etc., can solve the problems of inability to completely cover capacitors, large leakage current, increased leakage current, etc., and achieve excellent equivalent The effect of series resistance performance and excellent electrostatic capacitance performance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

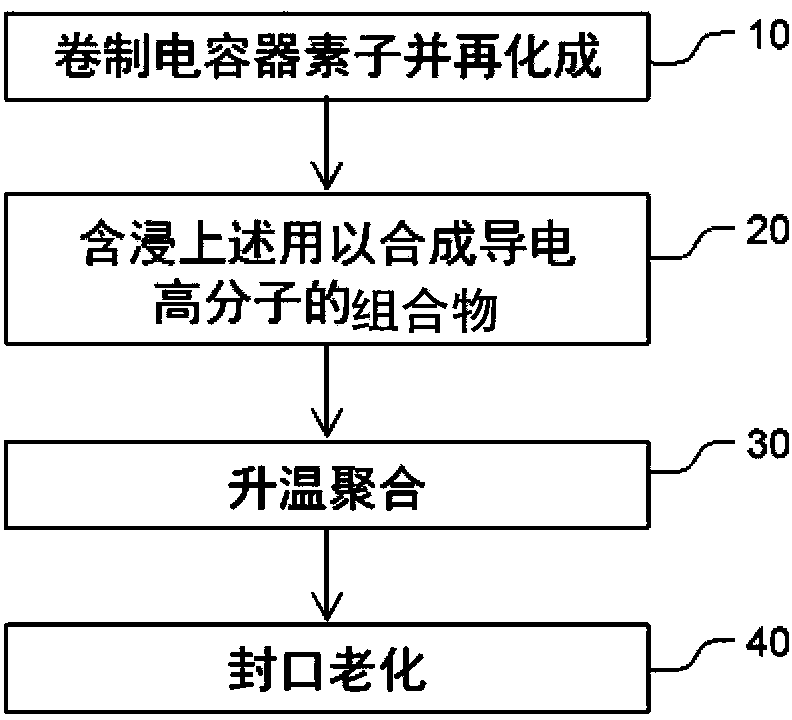

[0057] Pour 30wt% 3,4-ethylenedioxythiophene (EDOT) monomer solution with 5.0wt% nitrogen-containing polymer (polyvinylpyrrolidone) into a beaker, and dry it at 50°C to 125°C. The results are as follows: Figure 2A shown. After that, pour 50wt% ferric p-toluenesulfonate solution into the beaker, and raise the temperature to 170 degrees Celsius at a rate of 5 degrees per minute to carry out the polymerization reaction. The result is shown in 2B.

example 2-5

[0061] The positive electrode aluminum foil is electrochemically electrolyzed at 143 volts to form an aluminum oxide dielectric layer on the aluminum foil, and then a separator paper is sandwiched between the aluminum oxide dielectric layer and the electrochemically etched high surface area negative electrode aluminum foil, and then wound into a capacitor element . This element is re-formed by organic acid aqueous solution, and after repairing the damaged alumina dielectric layer, it is first impregnated with 3,4-ethylenedioxythiophene (EDOT) monomers listed in Table 1 and nitrogen-containing A polymer solution (a solution of polyvinylpyrrolidone (macromolecular weight average molecular weight: 1.3 million)) was impregnated with a solution containing 45 wt% of iron tosylate (Fe(III)p-tosylate). Then the temperature is raised to accelerate the progress of the polymerization reaction. During the reaction, the maximum temperature can reach 170 degrees Celsius to ensure the comple...

example 6

[0063] The solid electrolytic capacitor was fabricated by the same preparation method as in Example 2, except that the nitrogen-containing polymer was changed to polyvinylpyrrolidone with a weight average molecular weight of 10,000, and the addition amount was controlled at 5 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com