Heat resistant alcohol-soluble self-bonding paint used for self-bonding insulated winding wire and manufacturing method thereof

A technology of insulating windings and manufacturing methods, applied in the direction of organic insulators, plastic/resin/wax insulators, coatings, etc., can solve the problems of low temperature resistance, poor alcohol solubility, and self-adhesive three-layer insulated winding wires, etc. Achieve high withstand voltage, good high frequency performance, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Raw material ratio:

[0039] Raw material Weight Percentage (%)

[0040] m-cresol 90kg 43.63

[0041] Xylene 90kg 43.63

[0042] h 2 Nylon 15kg 7.27

[0043] E. s-7 Nylon 9kg 4.36

[0044] A S Resin 0.880kg 0.43

[0045] E. 51 Epoxy resin 1.320kg 0.64

[0046]

[0047] 594 curing agent 0.079kg 0.04

[0048] 206.279kg 100%

Embodiment 2

[0050] Raw material ratio:

[0051] Raw material Weight Percentage (%)

[0052] m-cresol 92.83kg 44.77

[0053] Xylene 92.83kg 44.77

[0054] h 2 Nylon 10.31kg 4.97

[0055] E. s-7 Nylon 9.88kg 4.77

[0056] A S Resin 0.21kg 0.1

[0057] E. 51 Epoxy resin 1.21kg 0.58

[0058] 594 curing agent 0.072kg 0.035

[0059]

[0060] 207.34kg 100%

Embodiment 3

[0062] Raw material ratio:

[0063] Raw material Weight Percentage (%)

[0064] m-cresol 72.2kg 35

[0065] Xylene 72.2kg 35

[0066] h 2 Nylon 41.26kg 20

[0067] E. s-7 Nylon 14.44kg 7

[0068] A S Resin 2.06kg 1

[0069] E. 51 Epoxy resin 3.34kg 1.62

[0070] 594 curing agent 0.20kg 0.097

[0071]

[0072] 205.7kg 100%

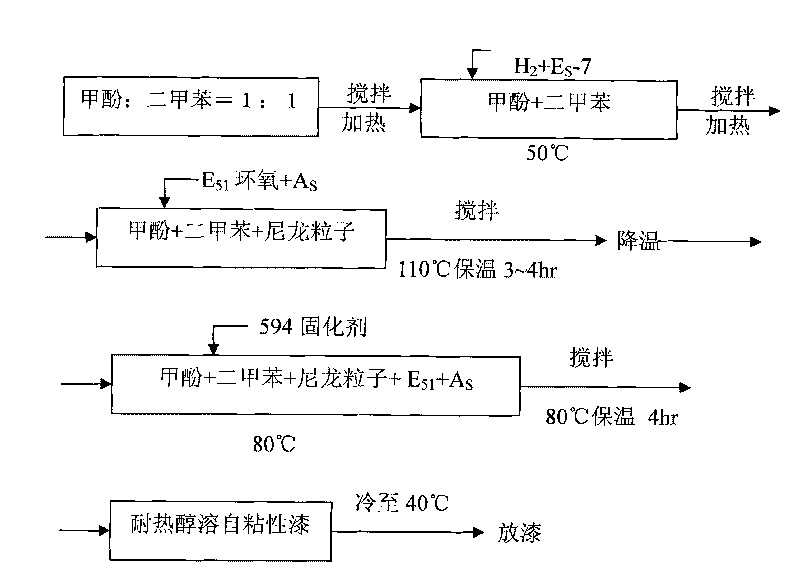

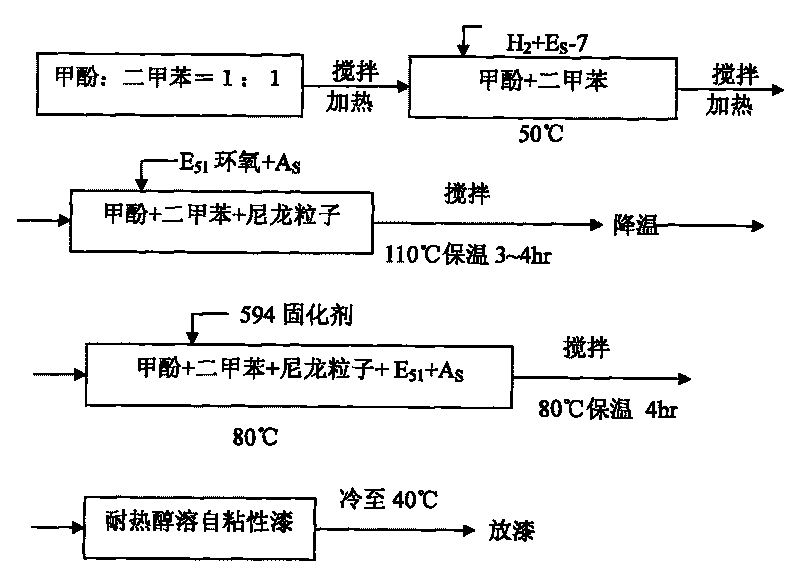

[0073] Use 200 liters of reactor equipment to prepare heat-resistant alcohol self-adhesive paint, and its preparation process route is as follows figure 1 As shown, the preparation method comprises the following process steps:

[0074] (1) Add the raw materials cresol and xylene into the reactor at a weight ratio of 1:1, stir and heat to 50°C;

[0075] (2) Add H in proportion to the material obtained in step (1) 2 Nylon, E s-7 Nylon stirring;

[0076] (3) Add E in proportion to the material obtained in step (2) 51 Epoxy resin, A S Stir the resin and heat it to 110°C, and keep it warm for 3 to 4 hours;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com