Low-loss high-voltage ceramic capacitor dielectric

A capacitor dielectric and high-voltage ceramic technology, which is applied to fixed capacitor dielectrics and components of fixed capacitors, etc., can solve the problems of complex preparation process, increased manufacturing cost, and high dielectric loss, and achieve cost reduction, low dielectric loss, and safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

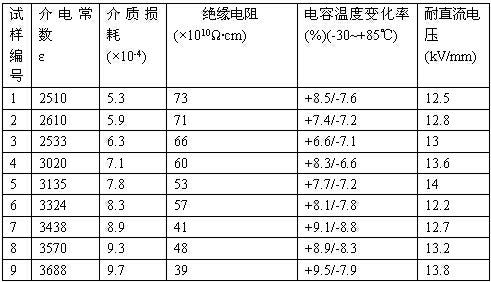

[0032] The present invention is described further in conjunction with embodiment now, and table 1 provides the formula of altogether 9 samples of the embodiment of the present invention.

[0033] The main raw material of the formula of the embodiment of the present invention totally 9 samples adopts ceramic capacitor grade pure, at first adopts conventional chemical raw material to synthesize BaTiO respectively with solid-phase method during preparation 3 , MgTiO 3 , BaZrO 3 , SrZrO 3 , CaTiSiO 3 , and then mix the ingredients according to the above formula, mix the prepared materials with distilled water or deionized water using a planetary ball mill, material: ball: water = 1:3: (0.6~1.0), after ball milling for 4~8 hours, dry to obtain Dry powder, add polyvinyl alcohol solution with a concentration of 10% (percentage by weight) accounting for 8-10% of its weight in the dry powder, granulate, pass through a 40-mesh sieve after mixing, and then proceed under a pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com