Low temperature sintering high voltage ceramic capacitor dielectric

A capacitor dielectric and high-voltage ceramic technology is applied in the field of low-temperature sintering high-voltage ceramic capacitor dielectrics, which can solve the problems of complex preparation process and increased manufacturing cost, and achieve the effects of cost reduction, low dielectric loss and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

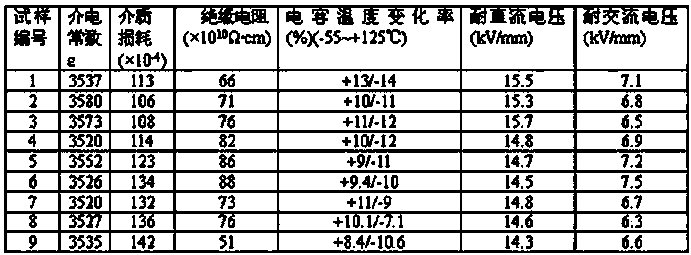

[0027] The present invention will be further described in conjunction with embodiment now. Table 1 provides the formulas of a total of 9 samples of the embodiments of the present invention.

[0028] The main raw material of the formula of the embodiment of the present invention altogether 9 samples adopts ceramic capacitor grade pure, at first adopts conventional chemical raw material to synthesize BaTiO respectively with solid phase method during preparation. 3 , SrTiO 3 , BaZrO 3 , ZnB 2 o 4 Glass powder and BaCu(B 2 o 5 ), then mix the ingredients according to the above formula, mix the prepared materials with distilled water or deionized water by planetary ball mill ball mill, material: ball: water = 1:3: (0.6~1.0) (mass ratio), ball mill for 4~8 hours Finally, dry the dry powder, add 8-10% of its weight to the dry powder with a concentration of 10% polyvinyl alcohol solution, granulate, pass through a 40-mesh sieve after mixing, and then grind it under a press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com