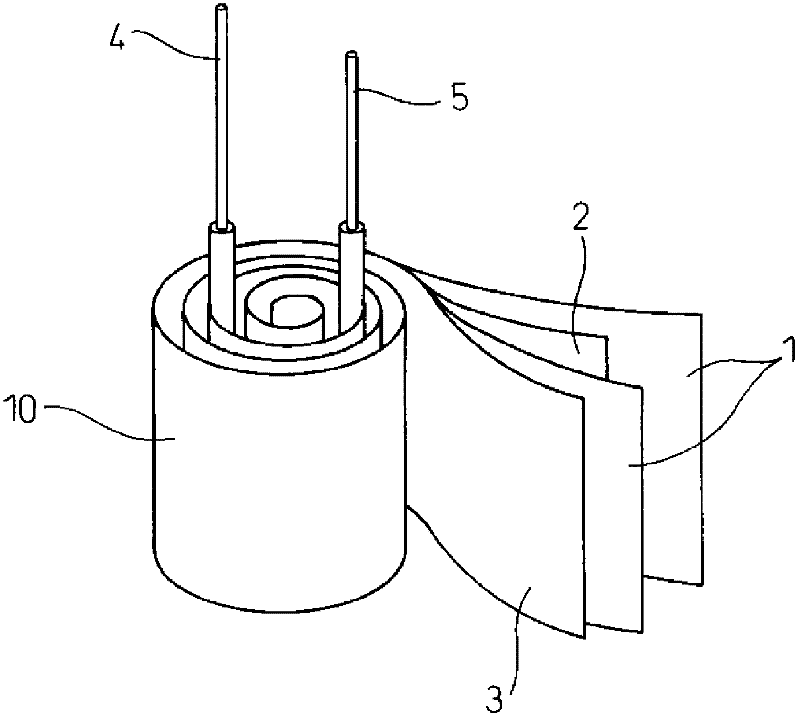

Solid electrolytic capacitor

A technology of solid electrolysis and capacitors, applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of inability to achieve high withstand voltage, narrow application range of solid electrolytic capacitors, and inability to achieve high-capacity capacitor miniaturization, etc. Effects of low ESR, high capacity ESR, and high withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

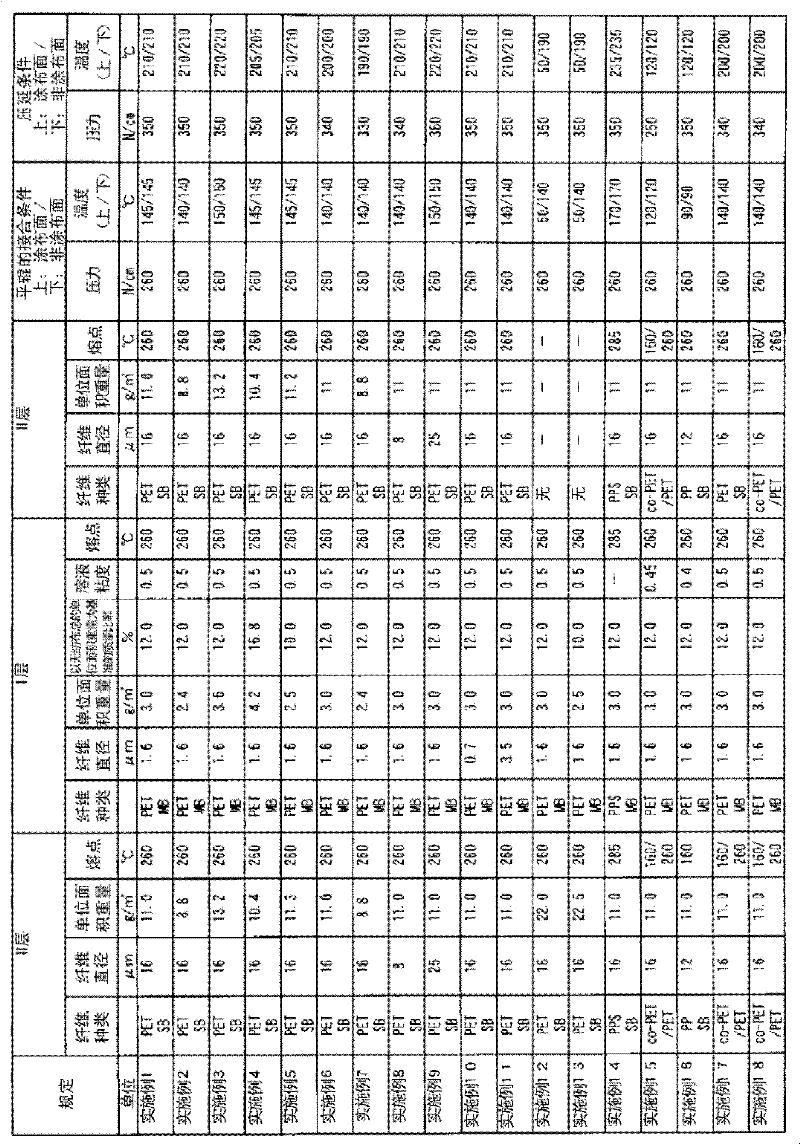

Embodiment 1~11、19、22、23、25、27

[0165] The multilayer nonwoven fabrics of Examples 1 to 11 were produced by the following method, and performance evaluation was implemented.

[0166] A nonwoven fabric layer (layer II) made of thermoplastic resin fibers is formed. Specifically, a solution of general-purpose PET (as a thermoplastic resin) (using OCP as a solvent, having a solution viscosity measured at a temperature of 35°C: ηsp / c=0.67) Viscosity tube measurement. Same as below.) By spunbonding method, at a spinning temperature of 300°C, the filament group was extruded toward the moving collecting net surface, and spinning was performed at a spinning speed of 4500m / min. Next, the filament group is sufficiently opened by corona charging with an electric charge of about 3 μC / g, and a long-fiber thermoplastic resin sheet is formed on the collecting net. The adjustment of fiber diameter is carried out by changing the drawing conditions.

[0167] Next, as the ultrafine fiber nonwoven fabric layer (layer I), using...

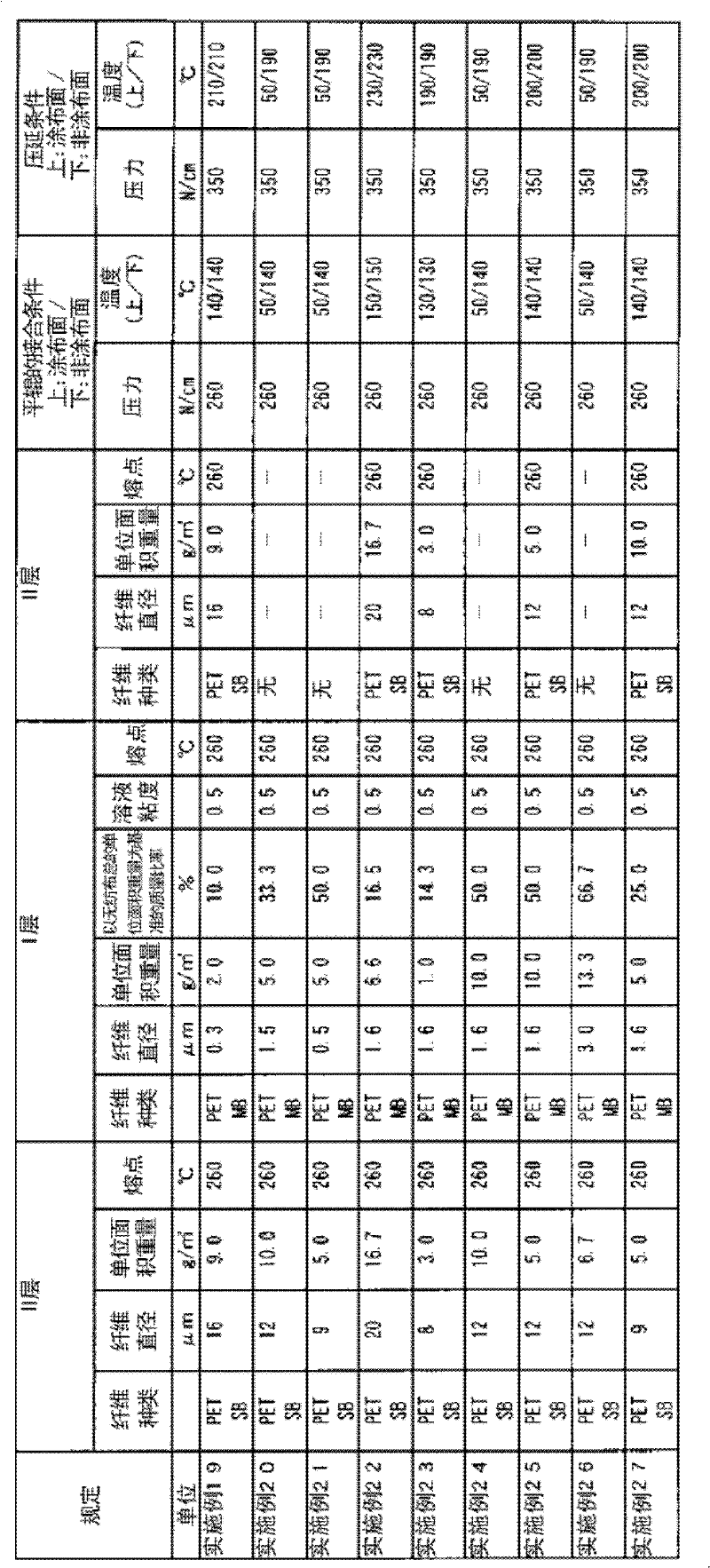

Embodiment 12、13、20、21、24、26

[0172] Unlike Examples 1-11, the same conditions as Examples 1-11 were used except the multilayer nonwoven fabric of a 2-layer structure (II layer and I layer). The conditions for forming a multilayer nonwoven fabric and the properties thereof are shown in Tables 1-2 and Tables 4-5, respectively. In addition, the capacitor performance is shown in Tables 7-8.

Embodiment 14

[0174] As the thermoplastic resin, PPS (Fortron manufactured by Polyplastics Corporation) was used. The conditions for forming a nonwoven fabric are as follows.

[0175] Layer II: Melt viscosity of resin: 70 g / 10 minutes (measured using a capillary rheometer, measurement conditions: load 5 kg, temperature 315.6° C.), spinning temperature: 320° C., spinning speed: 8000 m / min.

[0176] Layer I: melt viscosity of resin: 670g / 10min (measured by the same method as above, measurement conditions: load 5kg, temperature 315.6°C), spinning temperature: 340°C, heating air temperature: 390°C, heating air volume: 1000Nm 3 / hr / m.

[0177] In addition, the thermal bonding conditions using a flat roll are: line pressure: 260N / cm, roll temperature: up / down = 170°C / 170°C; calendering conditions are: line pressure: 350N / cm, roll temperature: up / down = 235°C / 235°C. The conditions for forming the multilayer nonwoven fabric and its properties are shown in Table 1 and Table 4, respectively. Oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com