Carbon ceramic shell-core-type three-dimensional particle electrode and preparing method thereof

A technology of particle electrodes and carbon ceramics, applied in chemical instruments and methods, water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve problems such as poor stability, high preparation cost, and single function, and achieve continuous Long service life, simple preparation process and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

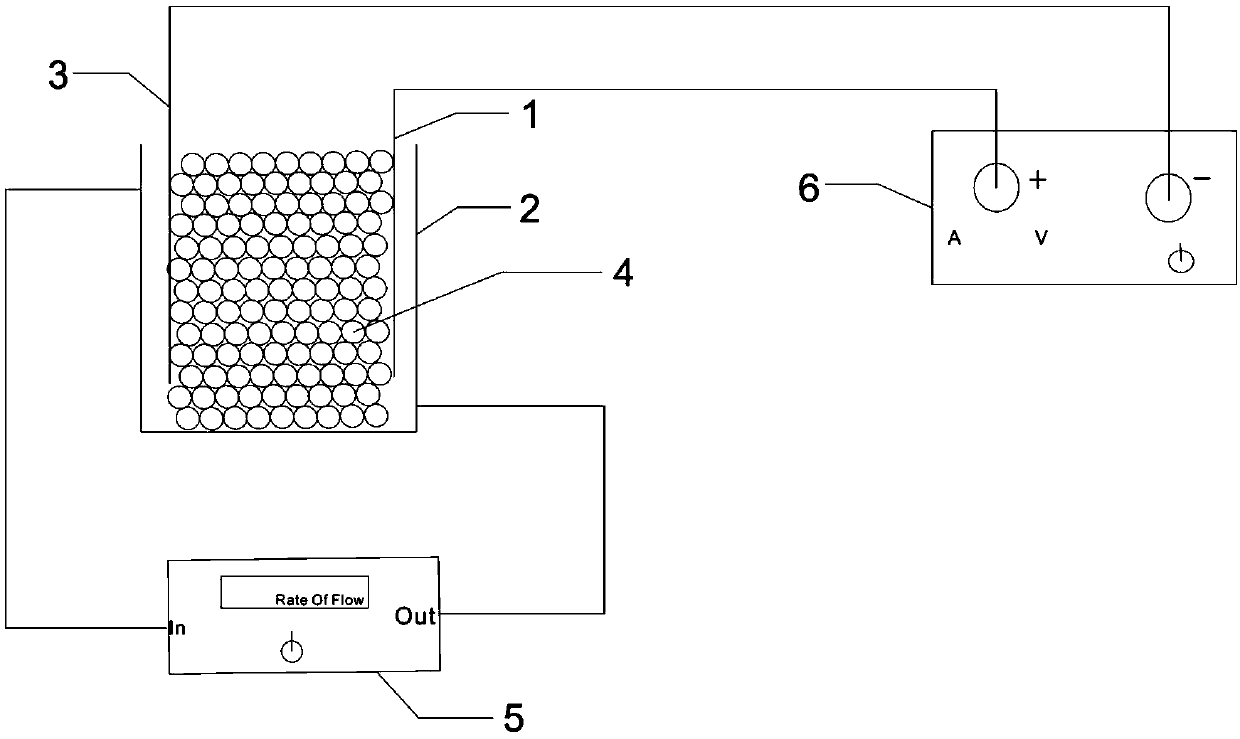

Method used

Image

Examples

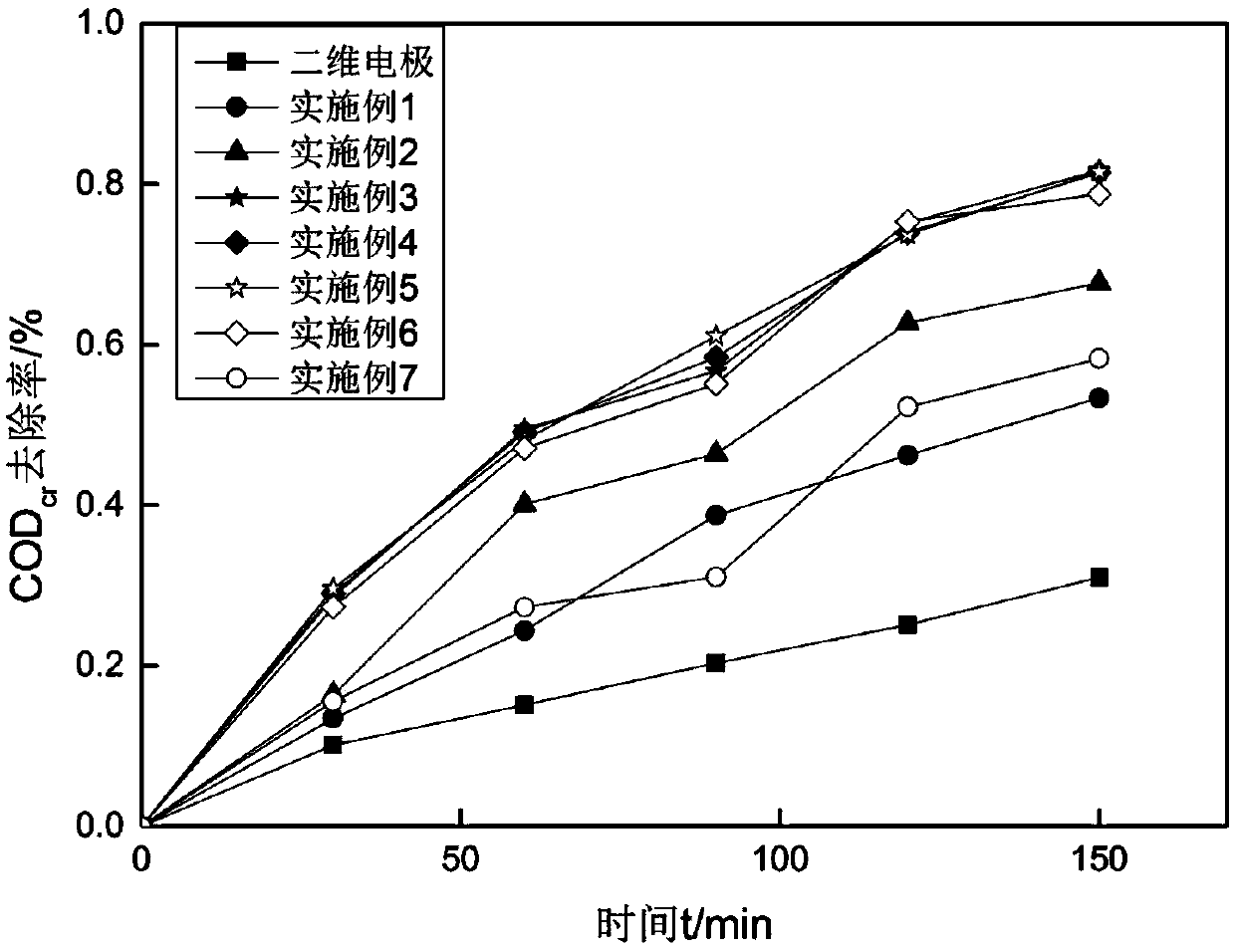

Embodiment 1

[0027] The carbon ceramic core-shell type three-dimensional particle electrode 4 includes clay 15wt%, and the bulk density of coal powder is 0.45t / m 3 -0.5t / m 3 , the metal salt whose content is 1wt% of coal powder.

[0028] A method for preparing a carbon ceramic core-shell type three-dimensional particle electrode, comprising the following steps:

[0029] Doping metal components into coal powder, the content of metal salt is 1wt% of coal powder, wherein the amount of zinc nitrate is 20wt% of the total metal salt, and the amount of copper sulfate is 25wt% of the total metal salt %, the amount of nickel oxide is 15wt% of the total metal salt, the amount of cobalt sulfate is 10wt% of the total metal salt, and the amount of ferrous sulfate is 20wt% of the total metal salt. The amount of tin is 5% of the amount of total metal salts, the amount of antimony oxide is 5wt% of the amount of total metal salts, and the coal powder and metal salts are mixed uniformly in the agglomerato...

Embodiment 2

[0031] The carbon ceramic core-shell type three-dimensional particle electrode 4 includes clay 20wt%, and the bulk density of coal powder is 0.45t / m 3 -0.5t / m 3 , the metal salt whose content is 3wt% of the coal powder.

[0032] A method for preparing a carbon ceramic core-shell type three-dimensional particle electrode, comprising the following steps:

[0033] Doping metal components into the coal powder, the content of the metal salt is 3wt% of the coal powder, wherein the amount of zinc sulfate is 20wt% of the total metal salt, and the amount of copper chloride is 20% of the total metal salt 25wt%, the amount of nickel sulfate is 15wt% of the total metal salt, the amount of cobalt nitrate is 10wt% of the total metal salt, the amount of ferrous sulfate is 20wt% of the total metal salt, sulfuric acid The amount of stannous is 5% of the amount of total metal salts, and the amount of antimony oxide is 5wt% of the amount of total metal salts. Coal powder and metal salts are mi...

Embodiment 3

[0035] The carbon ceramic core-shell type three-dimensional particle electrode 4 includes clay 20wt%, and the bulk density of coal powder is 0.45t / m 3 -0.5t / m 3 , the metal salt whose content is 5wt% of coal powder.

[0036] A method for preparing a carbon ceramic core-shell type three-dimensional particle electrode, comprising the following steps:

[0037] Doping metal components into the coal powder, the content of the metal salt is 5wt% of the coal powder, wherein the amount of zinc sulfate is 20wt% of the total metal salt, and the amount of copper chloride is 20% of the total metal salt 25wt%, the amount of nickel sulfate is 15wt% of the total metal salt, the amount of cobalt nitrate is 10wt% of the total metal salt, the amount of ferrous sulfate is 20wt% of the total metal salt, sulfuric acid The amount of stannous is 5% of the amount of total metal salts, and the amount of antimony oxide is 5wt% of the amount of total metal salts. Coal powder and metal salts are mixed un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com