A Mechanical Clamping Mechanism That Can Accurately Adjust Clamping Angle

A clamping mechanism and precise technology, applied in the direction of controlling mechanical energy, electromechanical devices, electrical components, etc., can solve the problems of reducing the accuracy of adjustment, low operation success rate, manpower, etc., to improve accuracy and stability, and improve adaptability Performance, accuracy-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

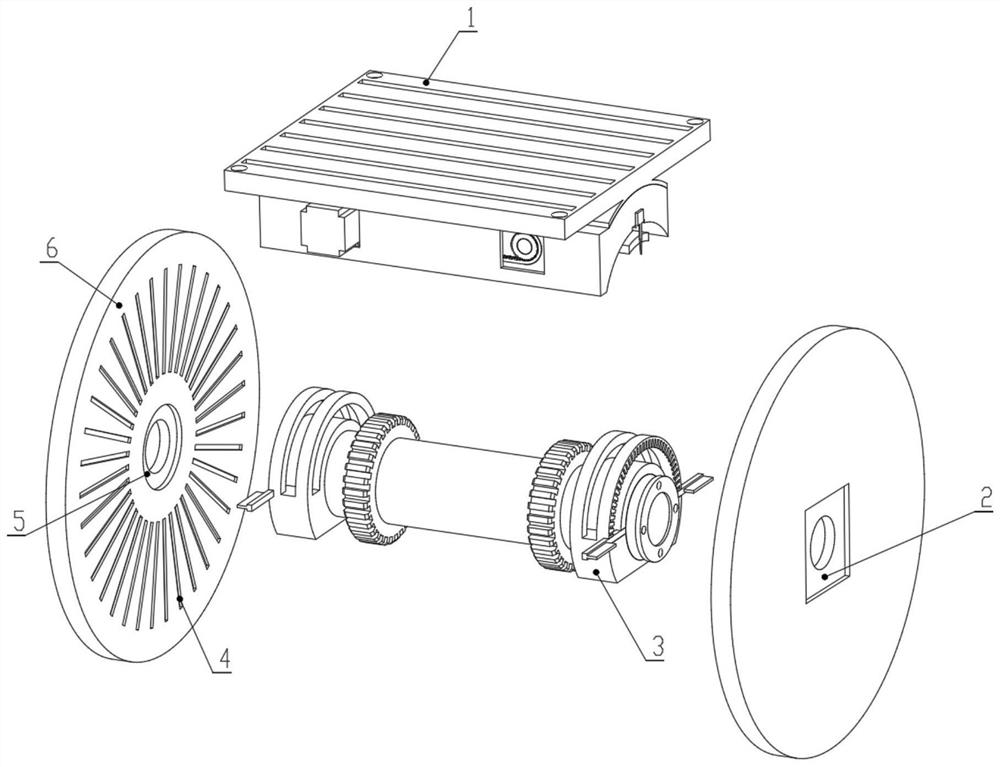

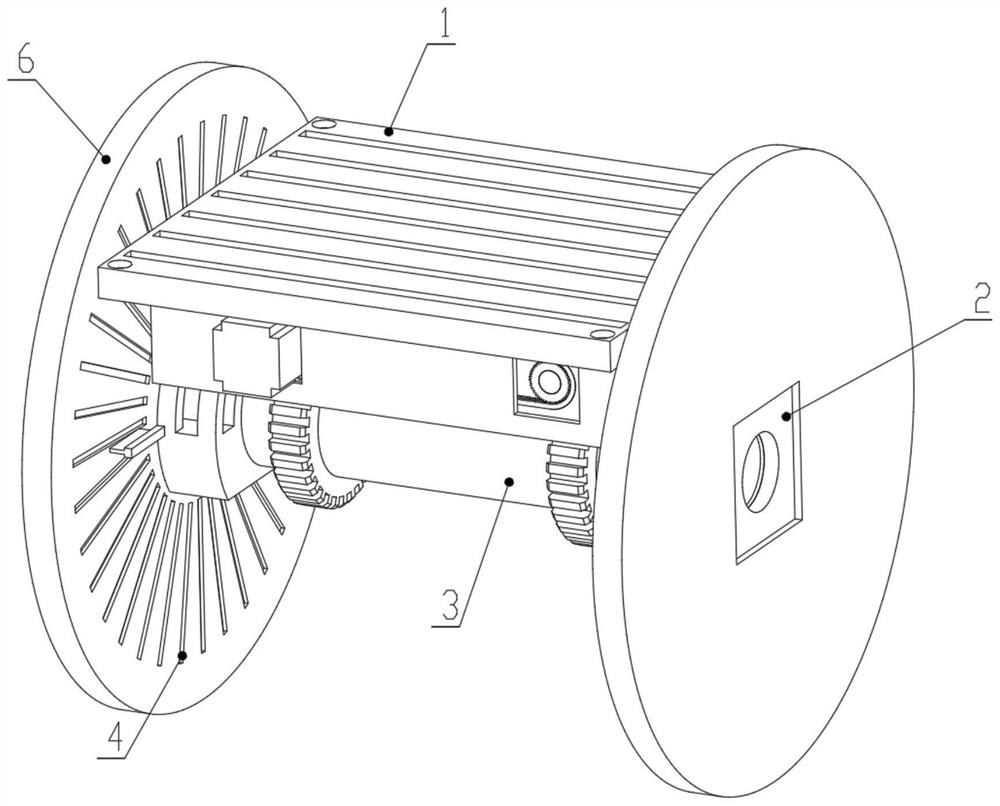

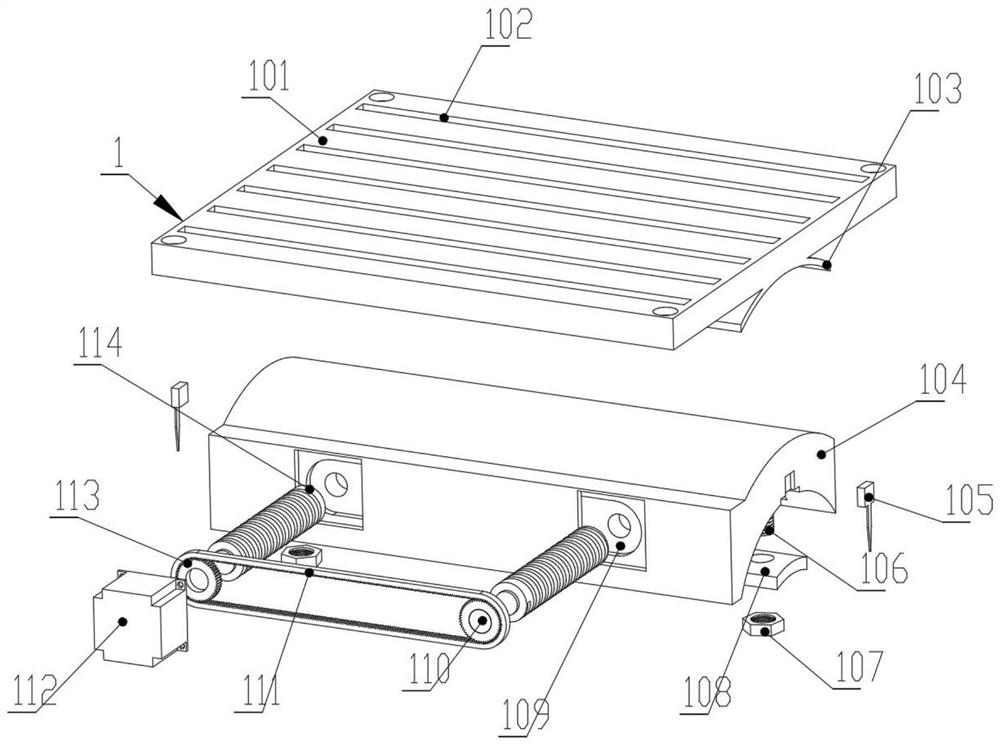

[0030] See Figure 1-8One embodiment of the present invention: a mechanical clamping mechanism that accurately adjusts clamping inclination angle, including a positioning mechanism 1, a motor tank 2, a support mechanism 3, a dial 4, a socket, a restricted card 6,

[0031] The side end surface of the support mechanism 3 is symmetrically rotated by the insertion groove 5, and the central end surface of the limit card 6 is uniformly is equivalent to the positioning disc 4, the limit card 6 The outer end surface is opened, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com