Steel ladle composite working lining and repairing method for slag line position thereof

A technology for working lining and slag line, which is applied in the field of lining repair of iron and steel metallurgical ladle, can solve the problems of spalling, high requirements for digging and repairing process, and shortening the service life of working lining, and achieves low production cost, safe use performance, and thermal shock stability. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

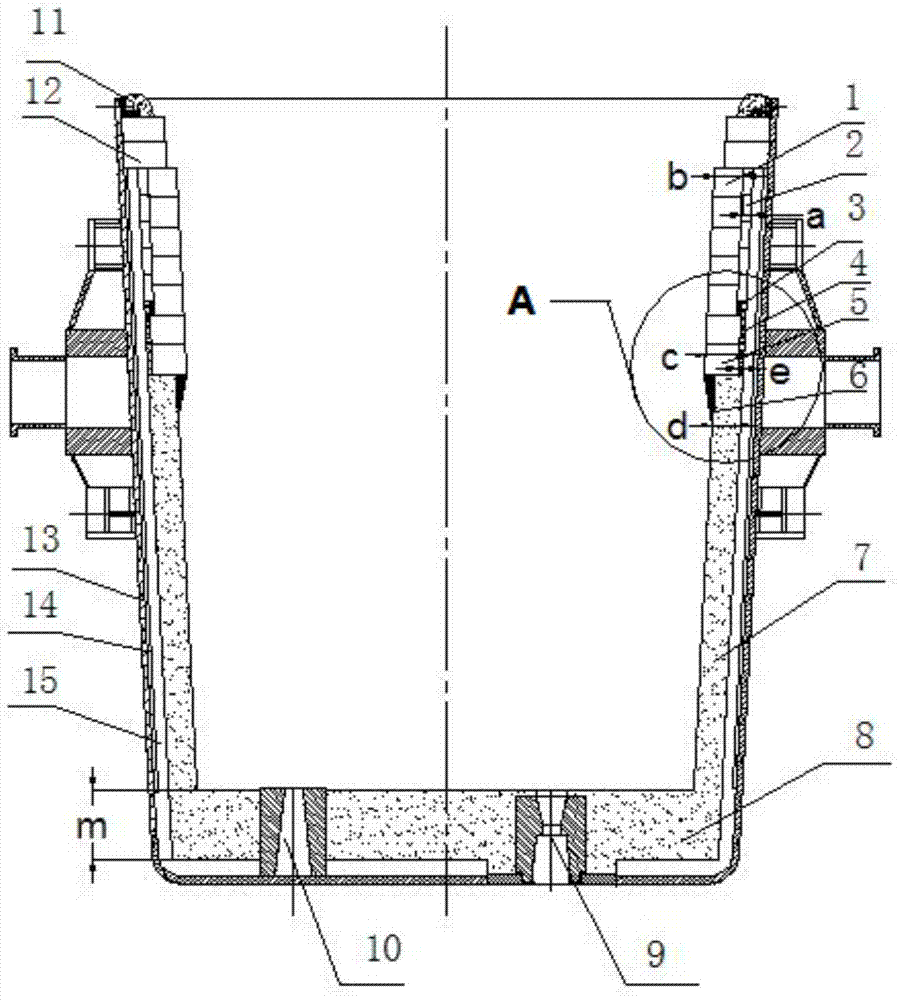

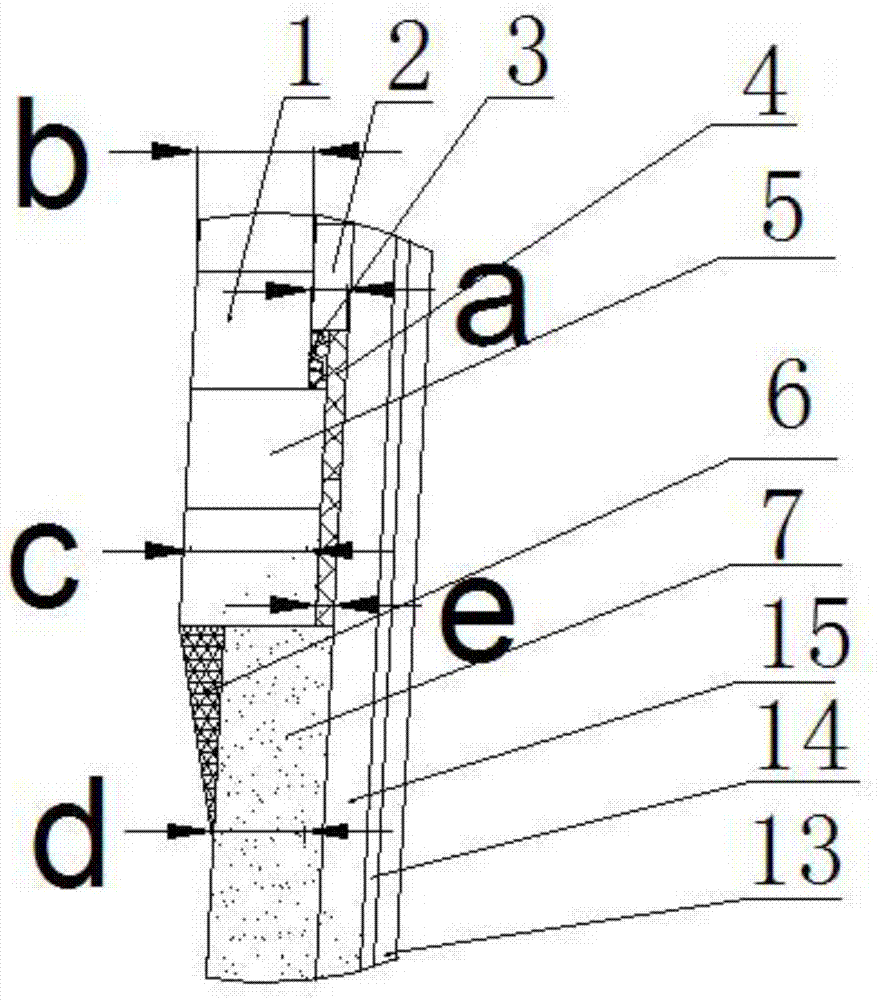

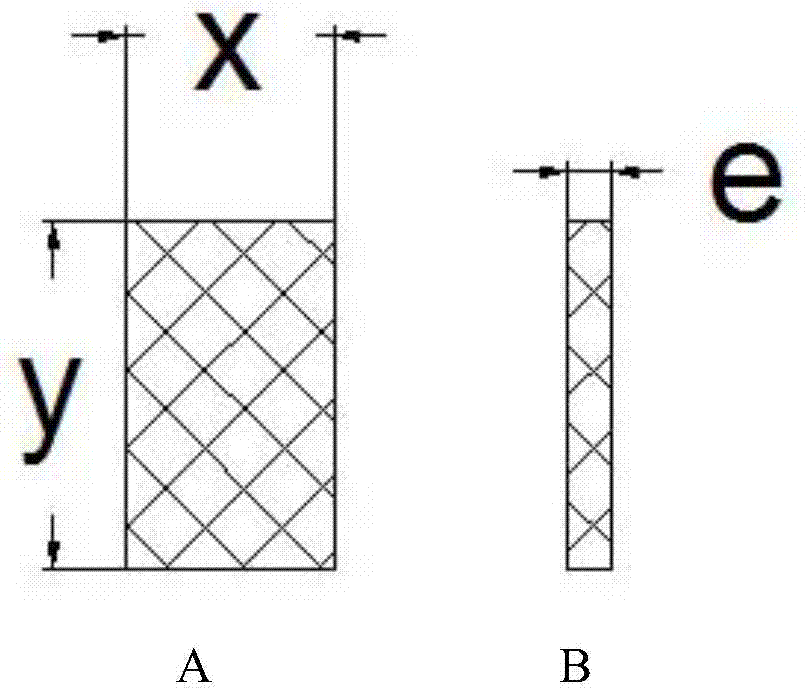

[0055] Such as figure 1 , figure 2 , image 3 As shown, a ladle composite working lining, including magnesia carbon brick 1 for the outer ring of the slag line, 2 aluminum magnesia carbon bricks for the inner ring of the slag line, 4 inner ring bricks at the bottom of the slag line, 5 outer ring bricks at the bottom of the slag line, leveling material 3, Gunning material layer 6, ladle wall working lining castable 7, ladle bottom working lining castable 8, ladle edge castable 11, single-ring cladding brick 12, and the inner wall of the ladle cladding 13 is provided with permanent lining heat-insulating and refractory in sequence The plate 14 and the permanent lining castable 15, on the top of the permanent lining castable 15 at the bottom of the bag, from bottom to top, are the bottom working lining castable 8, the wall working lining castable 7, the slag line part, and the single-ring cladding Bricks 12 and edge castables 11, the bottom-covered working lining castables 8 a...

Embodiment 2

[0080] Others are the same as embodiment 1, the difference is:

[0081] The inner ring brick 4 at the bottom of the slag line is set up by laying flat and vertically, and the number of layers of the inner ring brick 4 at the bottom of the slag line is 2 layers;

[0082] The aluminum-magnesium-carbon bricks 2 in the inner ring of the line are laid flat, and the number of layers of the aluminum-magnesian carbon bricks 2 in the inner ring of the slag line is 4 layers;

[0083] The outer ring brick 5 at the bottom of the slag line and the magnesia-carbon brick 1 at the outer ring of the slag line are all laid flat. The number of layers of the outer ring brick 5 at the bottom of the slag line is 3 layers. The number of layers of carbon brick 1 is 4 layers.

[0084] The single-ring cladding brick 12 is arranged close to the ladle shell 13, and the number of layers of the single-ring cladding brick 12 is 2 layers;

[0085] The length a of the alumina-magnesia-carbon brick 2 in the ...

Embodiment 3

[0103] Others are the same as embodiment 1, the difference is:

[0104] The inner ring brick 4 at the bottom of the slag line is set up vertically, and the number of layers of the inner ring brick 4 at the bottom of the slag line is 1 layer;

[0105] The alumina-magnesia-carbon bricks 2 in the inner ring of the slag line are laid flat, and the number of layers of the magnesia-carbon bricks 2 in the inner ring of the slag line is 7 layers;

[0106] The outer ring brick 5 at the bottom of the slag line and the magnesia-carbon brick 1 at the outer ring of the slag line are all set up by laying flat. The number of layers of carbon brick 1 is 7 layers.

[0107] The single-ring cladding brick 12 is arranged close to the ladle shell 13, and the number of layers of the single-ring cladding brick 12 is 1 layer;

[0108] The length a of the alumina-magnesia-carbon brick 2 in the inner ring of the slag line is 40 mm, and the length b of the magnesia-carbon brick 1 in the outer ring of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com