Electrode material for three-dimensional electrode and preparation method and application thereof

An electrode material and three-dimensional electrode technology, which are applied in chemical instruments and methods, water treatment parameter control, water/sewage treatment equipment, etc., can solve the problems of complex preparation process, poor stability, and high cost, and achieve simple and stable preparation methods. Good, high applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

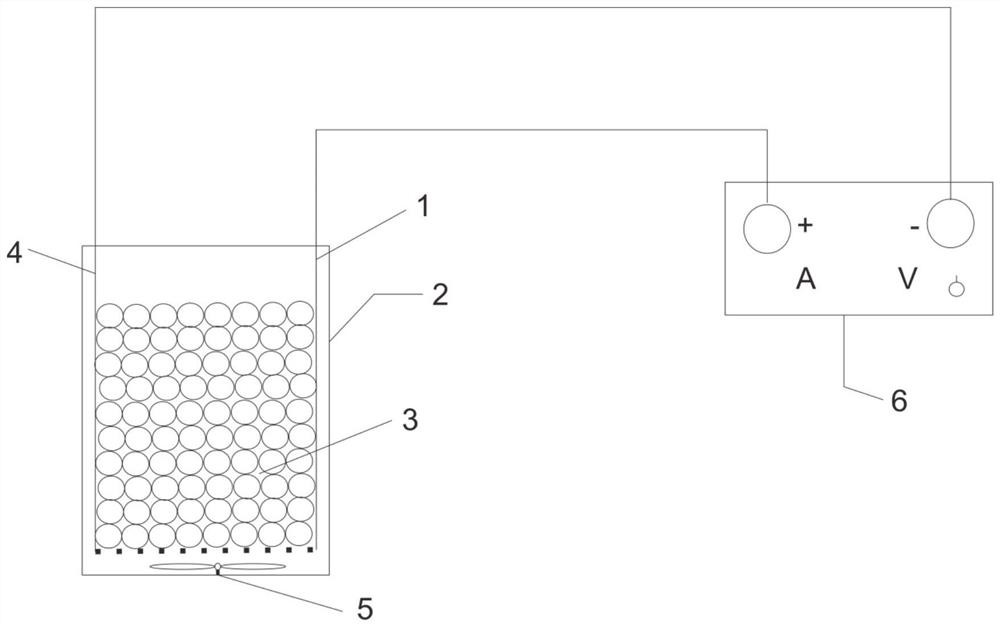

Method used

Image

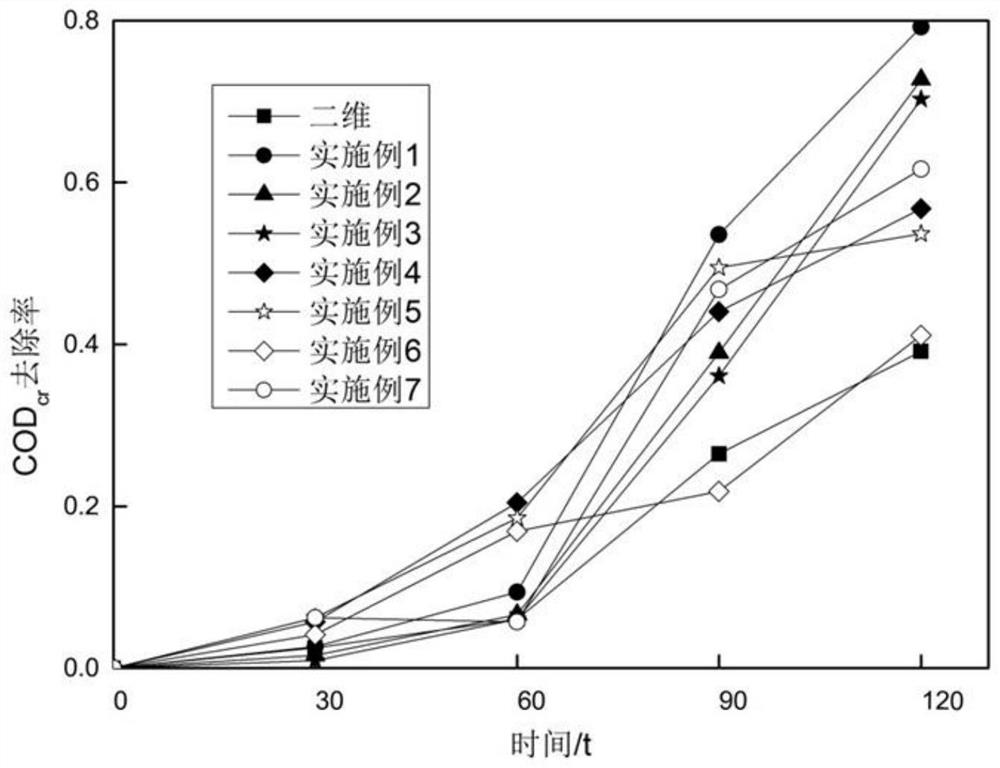

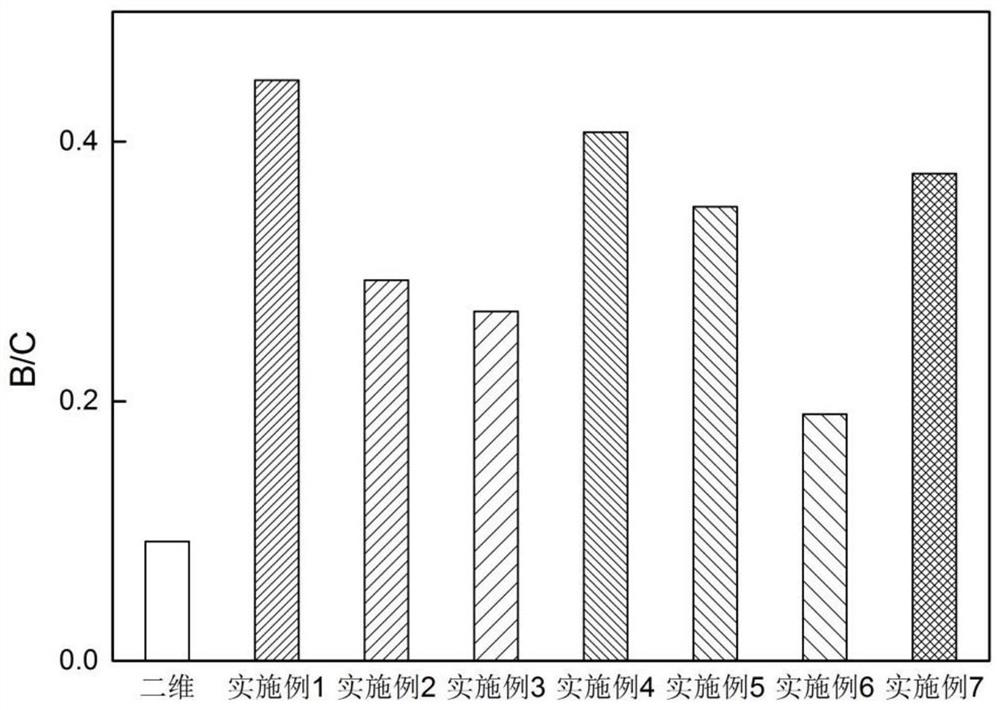

Examples

Embodiment 1

[0063] The electrode material A1 was prepared according to the following method:

[0064] (1) Add nonionic polyacrylamide (weight average molecular weight 150,000), ferric sulfate heptahydrate, copper sulfate pentahydrate, nickel nitrate hexahydrate, cerium nitrate hexahydrate and cobalt nitrate hexahydrate into water to prepare an impregnation solution. Among them, the concentration of non-ionic polyacrylamide is 20 mg / L, and the total concentration of metal ions is 30 mg / L. Fe 2+ 、Cu 2+ 、Ni 2+ 、Ce 3+ 、Co 2+ The mass ratio is 6:6:5:5:4.

[0065] (2) At 45°C, impregnate alumina honeycomb ceramics (diameter 2.5±0.5cm, height 1.5±0.5cm) with an average weight of 15.26g in the impregnation solution prepared in step (1), using excessive impregnation (impregnation Liquid and alumina honeycomb ceramic volume ratio is 2:1), impregnated for 2h.

[0066] (3) Hang the impregnated alumina honeycomb ceramics to dry, remove excess solution therein, and put it into an oven for drying...

Embodiment 2

[0069] Prepare and obtain electrode material A2 according to the following method:

[0070] (1) Add nonionic polyacrylamide (weight average molecular weight 150,000), ferric sulfate heptahydrate, copper sulfate pentahydrate, nickel nitrate hexahydrate, cerium nitrate hexahydrate and cobalt nitrate hexahydrate into water to prepare an impregnation solution. Among them, the concentration of non-ionic polyacrylamide is 20 mg / L, and the total concentration of metal ions is 20 mg / L. Fe 2+ 、Cu 2+ 、Ni 2+ 、Ce 3+ 、Co 2+ The mass ratio is 5:5:2:2:1.

[0071] (2) At 45°C, impregnate alumina honeycomb ceramics (diameter 2.5±0.5cm, height 1.5±0.5cm) with an average weight of 17.50g in the impregnating solution prepared in step (1), using excessive impregnation (impregnation Liquid and alumina honeycomb ceramic volume ratio is 2:1), impregnated for 2h.

[0072] (3) Hang the impregnated alumina honeycomb ceramics to dry, remove excess solution therein, and put it into an oven for dryi...

Embodiment 3

[0075] Prepare and obtain electrode material A3 according to the following method:

[0076] (1) Add nonionic polyacrylamide (weight average molecular weight 150,000), ferric sulfate heptahydrate, copper sulfate pentahydrate, nickel nitrate hexahydrate and cerium nitrate hexahydrate into water to prepare an impregnation solution. Among them, the concentration of non-ionic polyacrylamide is 15 mg / L, and the total concentration of metal ions is 20 mg / L. Fe 2+ 、Cu 2+ 、Ni 2+ 、Ce 3+ The mass ratio is 3:3:2:2.

[0077] (2) At 45°C, immerse alumina honeycomb ceramics (2.5±0.5cm in diameter, 1.5±0.5cm in height) with an average weight of 16.31g in the impregnating solution prepared in step (1), using the method of excessive impregnation (The volume ratio of impregnation solution to alumina honeycomb ceramics is 2:1), impregnation for 2h.

[0078] (3) Hang the impregnated alumina honeycomb ceramics to dry, remove excess solution therein, and put it into an oven for drying at 80° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com