Adsorption material, preparation method thereof, dye wastewater treatment method and application of adsorption material and dye wastewater treatment method

A technology for adsorbing material and dye wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] According to a particularly preferred embodiment of the present invention, the adsorption material is prepared according to the following method:

[0048] Preparation of impregnating solution: prepare an aqueous solution ( mn 2+ , Sn 2+ 、Ni 2+ , Sb 3+ 、Co 2 + The mass ratio is 3-6:3-6:2-3:2-3:1, wherein the concentration of non-ionic polyacrylamide is 25-30mg / L, metal cation (Mn 2+ , Sn 2+ 、Ni 2+ , Sb 3+ 、Co 2+ ) total concentration of 25-30mg / L.

[0049] Adsorption material preparation: The alumina honeycomb ceramics with a diameter of 2-3cm and a height of 1-2cm are impregnated in the above-mentioned impregnation solution by excessive impregnation. The volume ratio of alumina honeycomb ceramics to the impregnation solution is about 1: 8-12. Immersion time 1-3h, temperature 25-35 ℃. Hang the impregnated alumina honeycomb ceramics to dry in the air to remove excess solution, then put it into an oven, and dry it at 80-85° C. for 20-24 hours. Obtain adsorben...

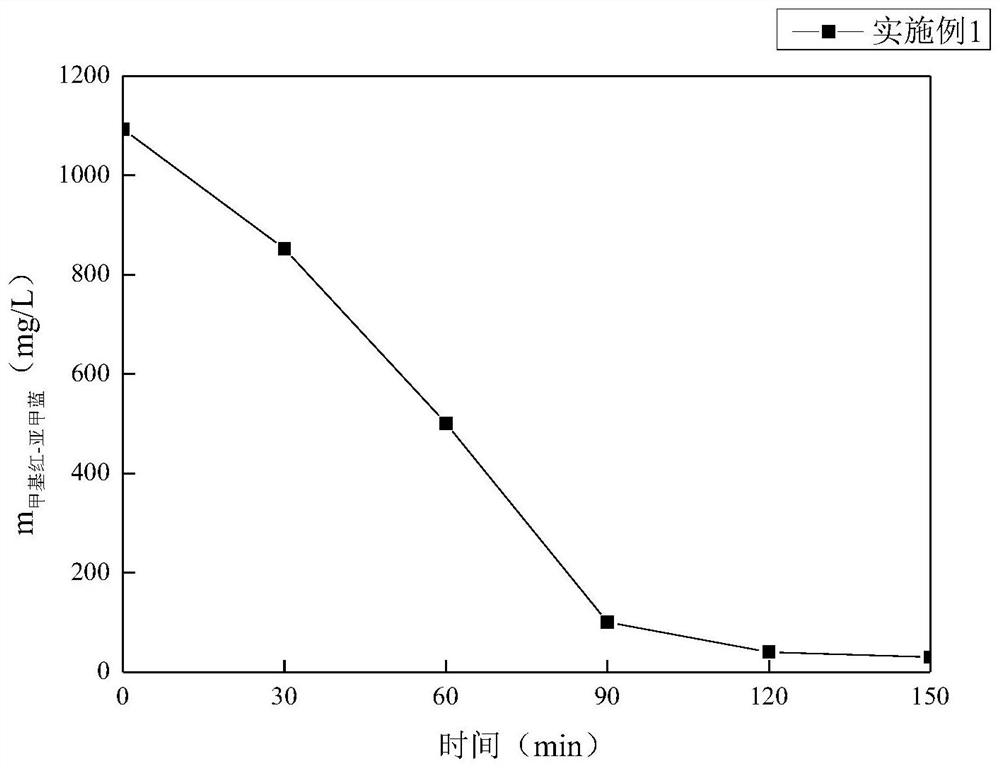

Embodiment 1

[0059] Adsorbent material A1 was prepared as follows:

[0060] Preparation of impregnation solution: prepare an aqueous solution (Mn 2+ , Sn 2+ 、Ni 2+ , Sb 3+ 、Co 2+ The mass ratio is 3:3:2:2:1), wherein, the concentration of non-ionic polyacrylamide is 30mg / L, metal cation (Mn 2+ , Sn 2+ 、Ni 2 + , Sb 3+ 、Co 2+ ) The total concentration is 30mg / L.

[0061] Adsorption material preparation: The alumina honeycomb ceramics with a diameter of 2.5±0.5cm and a height of 1.5±0.5cm are impregnated in the impregnation solution mentioned above by means of excessive impregnation. The volume ratio of the alumina honeycomb ceramics to the impregnation solution is about 1:10. Immersion time 2h, temperature 30 ℃. Hang the impregnated alumina honeycomb ceramics to dry in the air to remove excess solution, then put it into an oven, and dry it at 80°C for 24h. Adsorbent material A1 is obtained.

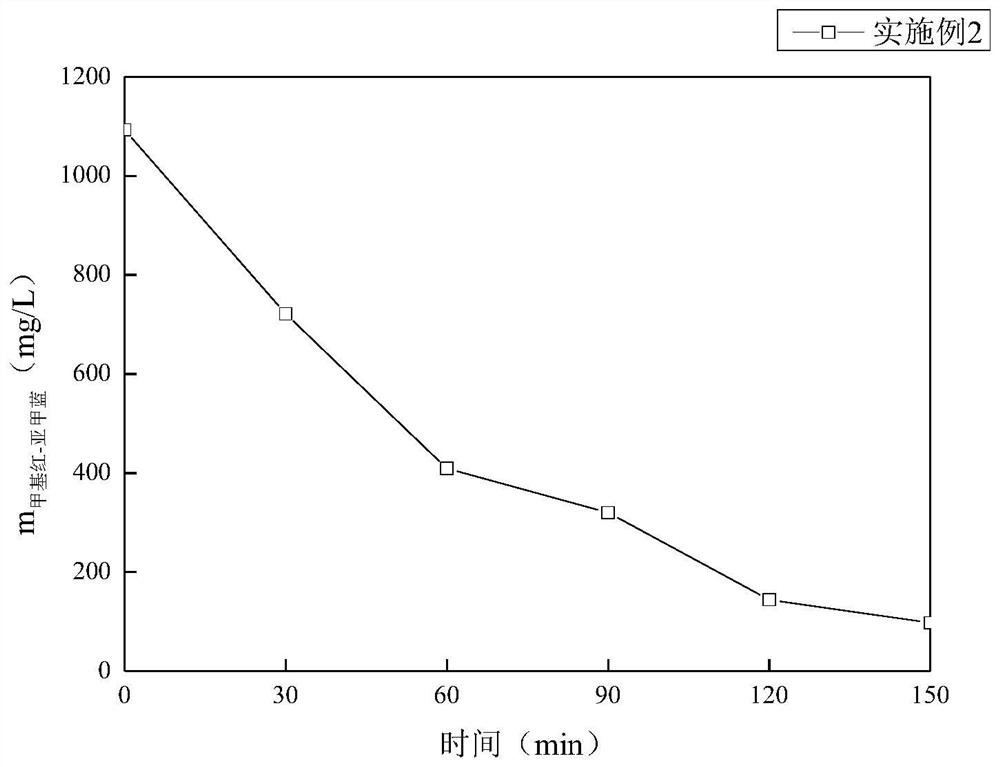

Embodiment 2

[0063] Adsorbent material A2 was prepared as follows:

[0064] Preparation of impregnation solution: prepare an aqueous solution (Mn 2+ , Sn 2+ 、Ni 2+ , Sb 3+ 、Co 2+ The mass ratio is 4:4:2:2:1), wherein, the concentration of non-ionic polyacrylamide is 10mg / L, metal cation (Mn 2+ , Sn 2+ 、Ni 2 + , Sb 3+ 、Co 2+ ) The total concentration is 20mg / L.

[0065] Adsorption material preparation: The alumina honeycomb ceramics with a diameter of 2.5±0.5cm and a height of 1.5±0.5cm are impregnated in the impregnation solution mentioned above by means of excessive impregnation. The volume ratio of the alumina honeycomb ceramics to the impregnation solution is about 1:10. Immersion time 2h, temperature 30 ℃. Hang the impregnated alumina honeycomb ceramics to dry in the air to remove excess solution, then put it into an oven, and dry it at 80°C for 24h. Adsorbent material A2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com