Bipolar three-dimensional electrode catalyst packing and preparation method thereof

A three-dimensional electrode and catalyst technology, which is applied in the field of bipolar three-dimensional electrode catalyst filler and its preparation, can solve the problems of short-circuit current, loss of active components, reduction of current efficiency, etc., achieve long continuous service life, improve mechanical strength, improve The effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

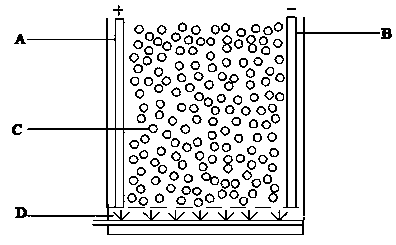

Method used

Image

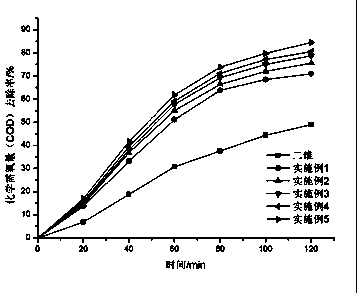

Examples

Embodiment 1

[0027] The bipolar three-dimensional electrode catalyst filler of this embodiment includes pottery clay, γ-Al 2 o 3 ; The clay 90 wt %, γ-Al 2 o 3 10wt%, additionally contains metal active components, the content of metal active components is clay and γ-Al 2 o 3 3wt% of the total amount.

[0028] The composition of the metal active component is: iron 20wt%, copper 30wt%, nickel 5wt%, zinc 10wt%, cobalt 3wt%, manganese 12wt%, tin 10wt%, antimony 8wt%, cerium 2wt%.

[0029] The bipolar three-dimensional electrode catalyst filler is spherical particles with a diameter of 10 mm.

[0030] The preparation method comprises the following steps: first, according to the ratio of pottery clay 90wt%, gamma-Al 2 o 3 10wt% weigh clay and γ-Al 2 o 3 , then add water equivalent to 67% of the weight of the pottery clay to the weighed pottery clay, stir to form a paste, and then add the weighed γ-Al 2 o 3 , stir evenly, then add the equivalent of pottery clay and γ-Al 2 o 3 3% met...

Embodiment 2

[0032] The bipolar three-dimensional electrode catalyst filler of this embodiment includes pottery clay, γ-Al 2 o 3 ; The clay 85 wt %, γ-Al 2 o 3 15 wt %, it also contains metal active components, and the content of metal active components is clay and γ-Al 2 o 3 5 wt % of the total amount.

[0033] The composition of the metal active component is: iron 25wt%, copper 25wt%, nickel 5wt%, zinc 10wt%, cobalt 1wt%, manganese 14wt%, tin 8wt%, antimony 7wt% and cerium 5wt%, each component weight The sum of the percentages is 100 wt %.

[0034] The bipolar three-dimensional electrode catalyst filler is spherical particles with a diameter of 4 mm.

[0035] The preparation method comprises the following steps: first according to the ratio of pottery clay 85wt%, gamma-Al 2 o 3 15wt% weigh clay and γ-Al 2 o 3 , then add water equivalent to 85% of the weight of the pottery clay to the weighed clay, stir to form a paste, and then add the weighed γ-Al 2 o 3 , stir evenly, then ...

Embodiment 3

[0037] The bipolar three-dimensional electrode catalyst filler of this embodiment includes pottery clay, γ-Al 2 o 3 ; The clay 80 wt %, γ-Al 2 o 3 20 wt %, it also contains metal active components, and the content of metal active components is clay and γ-Al 2 o 3 6 wt % of the total amount.

[0038] The composition of the metal active component is: iron 30wt%, copper 20wt%, nickel 5wt%, zinc 8wt%, cobalt 2wt%, manganese 15wt%, tin 10wt%, antimony 8wt% and cerium 2wt%, each component weight The sum of the percentages is 100%.

[0039] The bipolar three-dimensional electrode catalyst filler is spherical particles with a diameter of 5 mm.

[0040] The preparation method comprises the following steps: first, according to the ratio of pottery clay 80wt%, γ-Al 2 o 3 20wt% weigh clay and γ-Al 2 o 3 , then add water equivalent to 90% of the weight of the pottery clay to the weighed pottery clay, stir it into a paste, and then add the weighed γ-Al 2 o 3 , stir evenly, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com