A Plasma Synthetic Jet Generator with Controllable Cavity Temperature and Its Application

A plasma and synthetic jet technology, applied in the direction of plasma, electrical components, etc., can solve the problems of improving performance, low jet velocity, and reduced jet flow, so as to improve continuous service life, increase jet intensity, and increase discharge energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

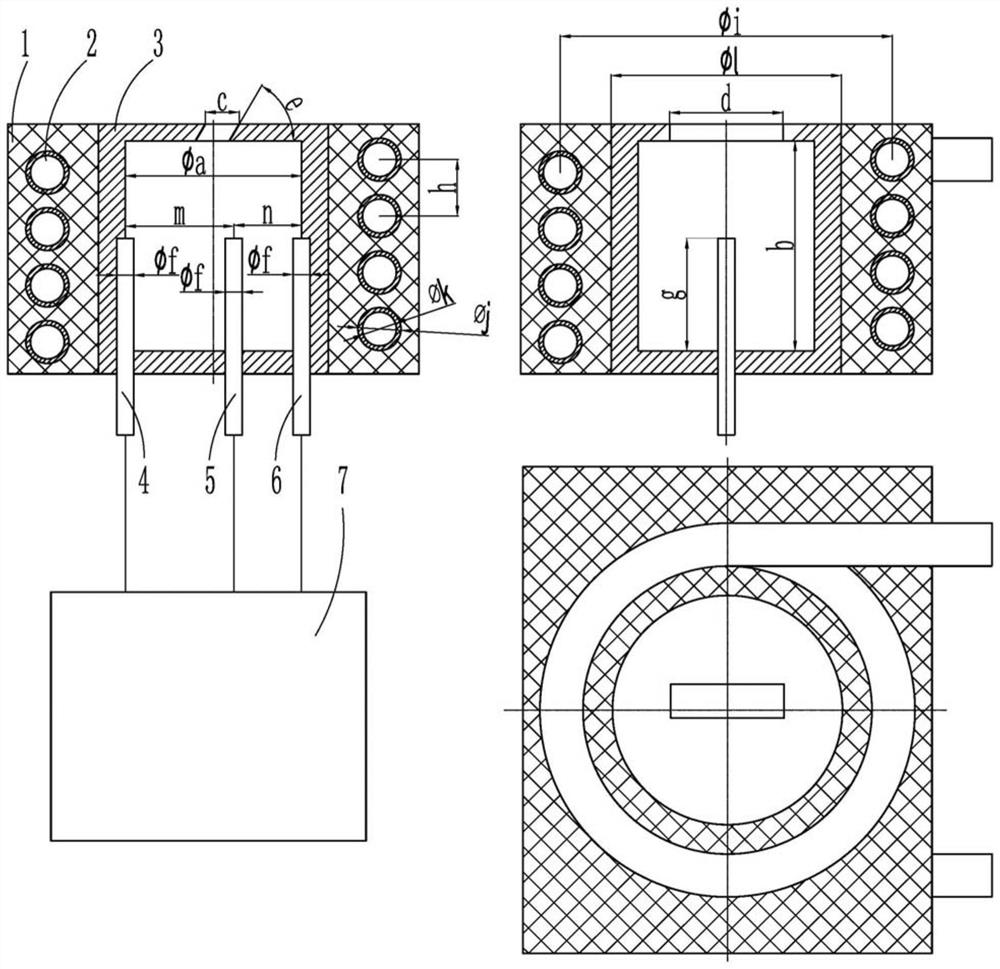

[0026] figure 1 It is a schematic structural diagram of a plasma synthetic jet generator with controllable cavity temperature provided by an embodiment of the present invention. Such as figure 1 As shown, the plasma synthetic jet generator with controllable chamber temperature includes: thermal management components and plasma synthetic jet generator; electrodes include anode 4, cathode 6 and excitation pole (also known as trigger pole) 5; the chamber Body 3, the electrode and the DC high-voltage pulse power supply 7 constitute a plasma synthetic jet generator; the heat management component includes the heat-conducting support structure 1 and heat pipe 2; the DC high-voltage pulse power supply and the electrode pass through a wire Connected; the electrodes form a high-frequency arc under the excitation of the DC high-voltage pulse power supply (voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com