Electrolytic ozone generator and preparation technique for cathode catalysis layer thereof

An ozone generator and cathode catalysis technology, applied in the field of electrochemistry, can solve the problems of low current efficiency, short electrode life and high ozone cost, and achieve the effects of improving current efficiency, stable performance and prolonging continuous service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

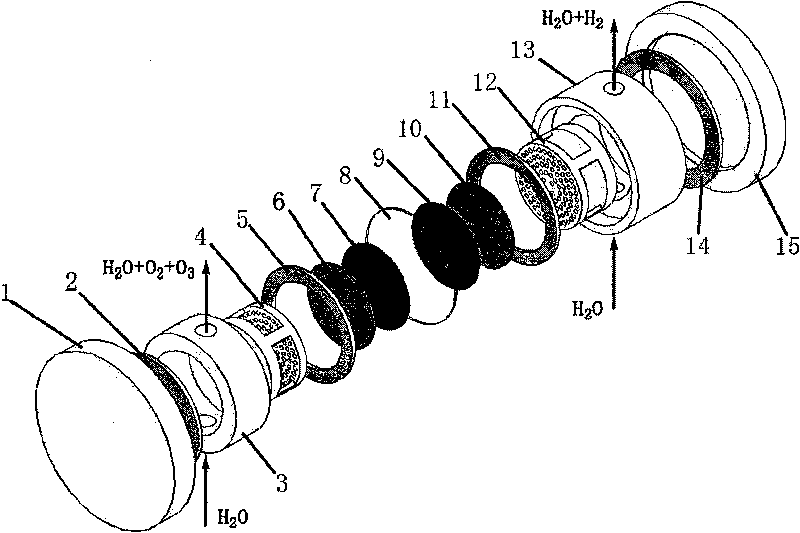

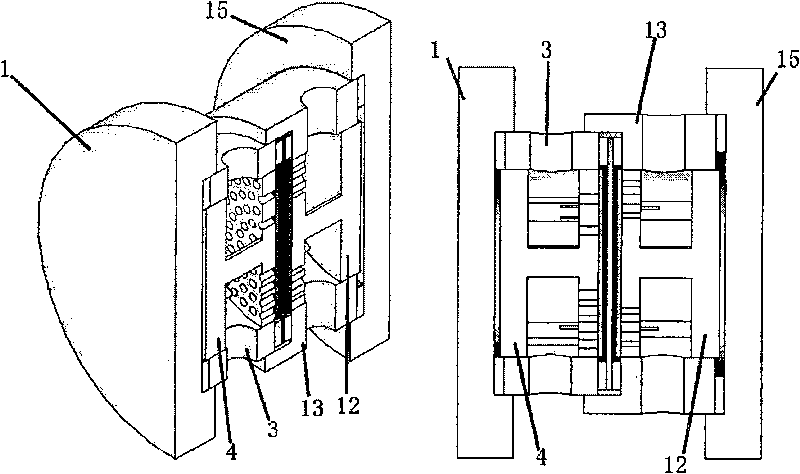

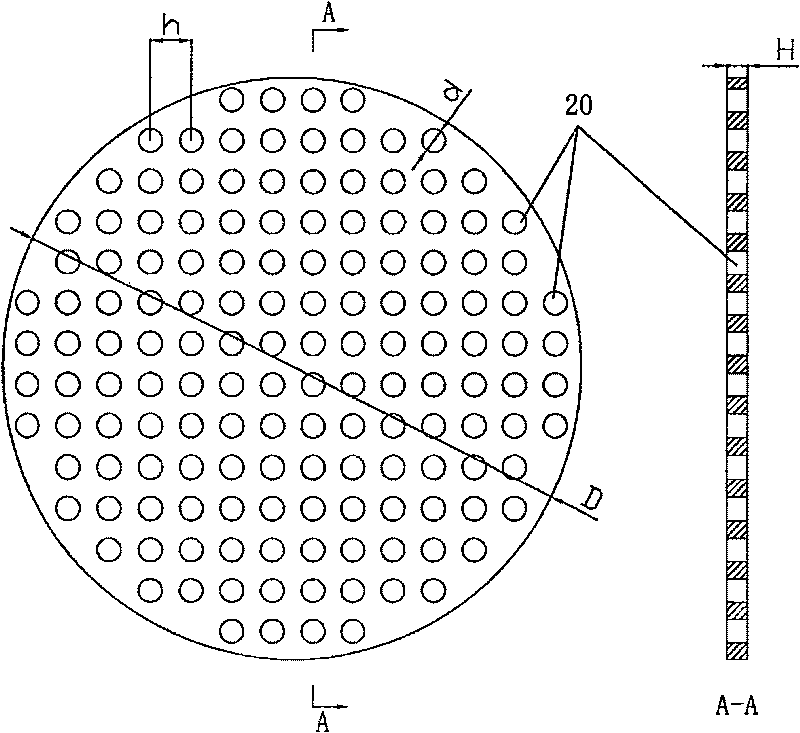

[0035] The thickness (H) of disc boron carbon anode piece (7) is 0.4mm, and diameter (D) is 35mm; The aperture (d) of axial small through hole (20) is 0.2mm, adjacent small through hole (20 ) hole spacing (h) is 3.0mm.

[0036] The preparation technology of cathode catalyst layer (9) is: the carbon-supported platinum and Nafion emulsion with a platinum loading of 10% are mPt:m Nafion = 1:1.8 mix, add appropriate amount of isopropanol and stir evenly, stir in a water bath at 65°C until it becomes a paste, roll at 25°C to form a film with a thickness of 0.15±0.02mm, dry at 60°C and cut into desired The size is the cathode catalytic layer.

[0037] The processed disc-shaped boron carbon anode sheet (7) and the prepared cathode catalytic layer (9) are installed in such as figure 1 or figure 2 In the shown electrolysis chamber, pure water is passed through the cathode and anode of the electrolysis chamber respectively, and the water flow rate is 4L / min.

Embodiment 2

[0039] The thickness (H) of disc boron carbon anode piece (7) is 0.8mm, and diameter (D) is 55mm; The aperture (d) of axial small through hole (20) is 0.5mm, adjacent small through hole (20 ) hole spacing (h) is 3.5mm.

[0040] The preparation technology of cathode catalyst layer (9) is: the carbon-supported platinum and Nafion emulsion with a platinum loading of 10% are mPt:m Nafion = 1:1.5 mixing, add appropriate amount of isopropanol and stir evenly, stir in 75°C water bath until paste, roll into 0.15±0.02mm thick film at 35°C, dry at 70°C and cut into required The size is the cathode catalytic layer.

[0041] The processed disc-shaped boron carbon anode sheet (7) and the prepared cathode catalytic layer (9) are installed in such as figure 1 or figure 2 In the shown electrolysis chamber, pure water is passed through the cathode and anode of the electrolysis chamber respectively, and the water flow rate is 10L / min.

Embodiment 3

[0043] The thickness (H) of disc boron carbon anode piece (7) is 1.2mm, and diameter (D) is 75mm; The aperture (d) of axial small through hole (20) is 0.8mm, adjacent small through hole (20 ) hole spacing (h) is 4.0mm.

[0044] The preparation technology of cathode catalyst layer (9) is: the carbon-supported platinum and Nafion emulsion with a platinum loading of 20% are mPt:m Nafion = 1:1.2 mix, add appropriate amount of isopropanol and stir evenly, stir in a water bath at 70°C until it becomes a paste, roll at 30°C to form a film with a thickness of 0.15±0.02mm, dry at 80°C and cut into desired The size is the cathode catalytic layer.

[0045] The processed disc-shaped boron carbon anode sheet (7) and the prepared cathode catalytic layer (9) are installed in such as figure 1 or figure 2 In the shown electrolysis chamber, pure water is passed through the cathode and anode of the electrolysis chamber respectively, and the water flow rate is 18L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com