An anti-reconnaissance and camouflage functional inorganic pigment, inorganic printing paint and fabric

A printing paint and inorganic pigment technology, applied in the field of pigments, can solve the problems of incomplete camouflage functionality, less pigment anti-reconnaissance function, etc., and achieve the effects of improving light fastness, excellent weather resistance, and improving wave absorbing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

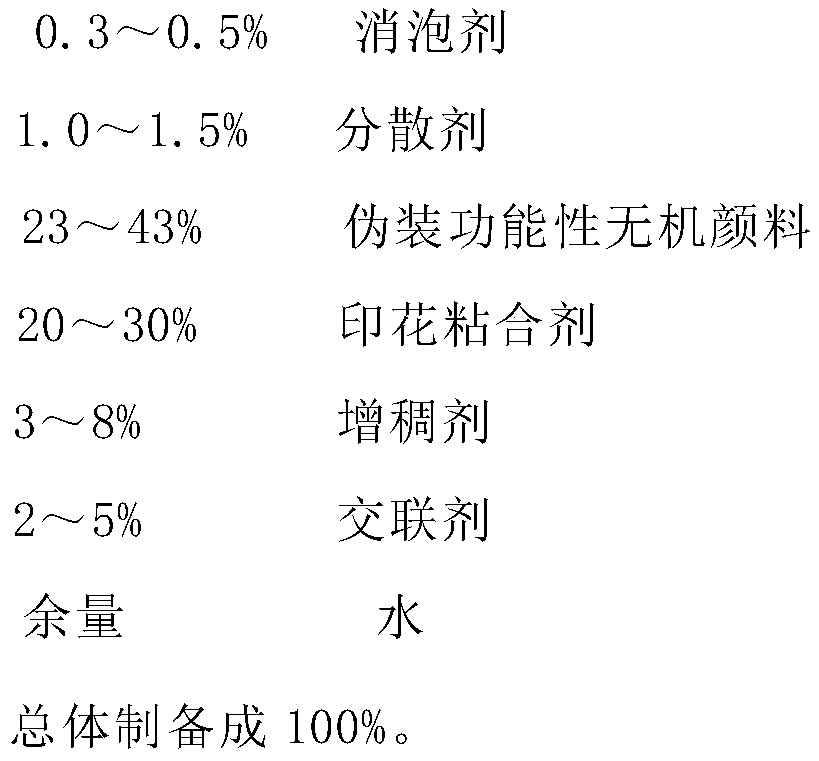

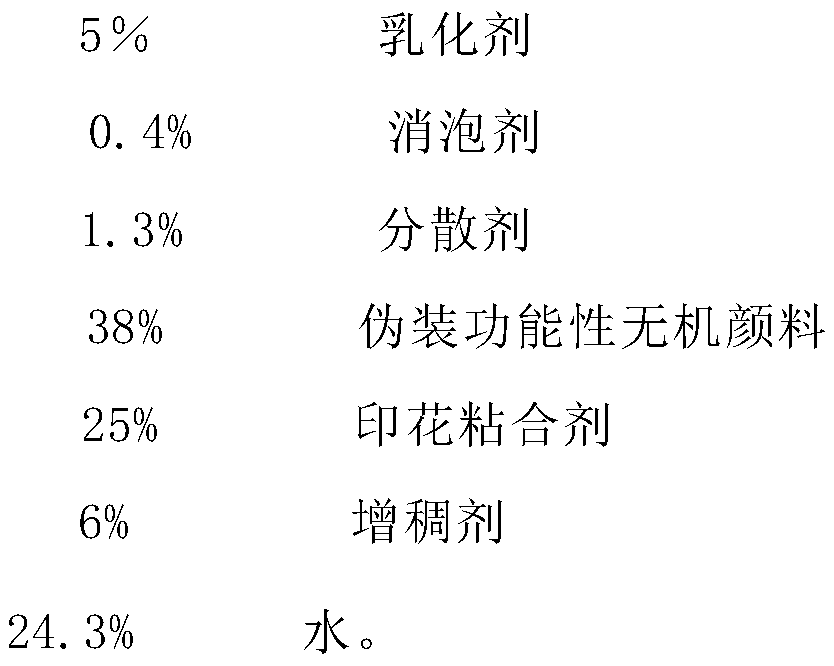

Embodiment 1

[0028] This embodiment discloses an anti-reconnaissance and camouflage functional inorganic pigment. The anti-reconnaissance and camouflage functional inorganic pigment includes titanium yellow, titanium chrome brown, cobalt blue, chrome green, titanium chrome yellow, titanium manganese brown, titanium cobalt green, Titanium Nickel Yellow, Copper Chrome Black and Iron Chrome Black. In this embodiment, functional inorganic pigments can be made into inorganic printing paints, that is, after adding emulsifiers, dispersants, defoamers, etc., and water to functional inorganic pigments, the near-infrared reflectance and Lightness L, a, b value, (L value represents lightness, a value represents the green-red value of color, and b value represents the blue-yellow value of color.) Obtain the color appearance that satisfies demand; In another embodiment of the present invention, Functional inorganic pigments can be made into inorganic coatings, that is, add organic solvent toluene to fu...

Embodiment 2

[0053] On the basis of embodiment 1, the printing anti-reconnaissance equipment fabric making method in embodiment 1 is as follows:

[0054] 1. Base cloth preparation.

[0055] Inorganic pigment printing has relatively strict requirements on the porosity of the base fabric. For the polyester filament base fabric, while meeting the mechanical strength requirements, its actual porosity must not be less than 12% to 18%. (For example: use 500D high-strength polyester filament produced by Jiangsu Hengli, plain weave structure, width 155cm, warp density of 180-200 per 10cm, weft density of 150-160 per 10cm.)

[0056] 2. Printing treatment

[0057] (1) Preparation of digital camouflage printing screen. According to the camouflage design, the printing screen is made, the mesh number of the screen is also 100-120 mesh, the width is 1.5m, and the flower back length is 1018mm.

[0058] (2) Printing production equipment.

[0059] Use the rotary screen printing machine of Zimmer Compan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com