An intelligent whole-process temperature-controlled steam curing kiln

A technology of steam curing and the whole process, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of low intelligence and poor intelligent control, so as to ensure the production of high-quality products, good intelligent control, and qualified products rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

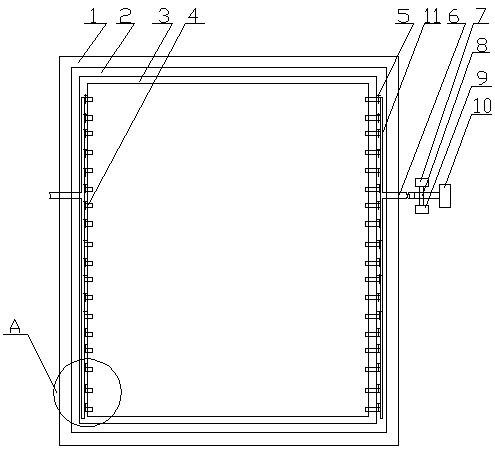

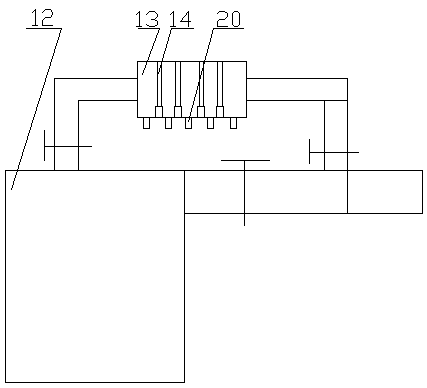

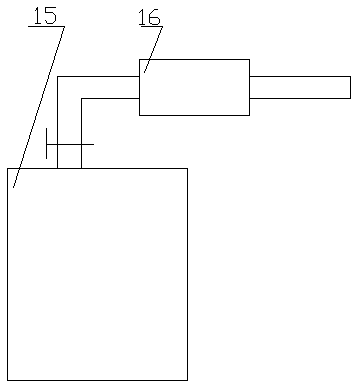

[0035] Embodiment 1: An intelligent full-process temperature-controlled steam curing kiln, including a kiln body, an adjustment mechanism set in the kiln body for adjusting temperature and humidity, and a control mechanism set outside the kiln body to obtain a suitable environment in the kiln body A control module; the adjustment mechanism includes a temperature adjustment module and a humidity adjustment module, wherein the temperature adjustment module is used for adjustment when the temperature is unbalanced; the humidity adjustment module is used for adjustment when the humidity is unbalanced.

[0036] The kiln body is sequentially provided with an insulation layer 3, a base frame layer 2 and a protective layer 1 from the inside to the outside, and a number of air nozzles 4 for temperature and humidity adjustment are arranged at the insulation layer 3, and the air nozzles 4 and An air pipe 11 is provided between the pedestal layer 2 and the protective layer 1, and the air p...

Embodiment 2

[0042] Embodiment 2: An intelligent full-process temperature-controlled steam curing kiln, including a kiln body, an adjustment mechanism set in the kiln body for adjusting temperature and humidity, and a control mechanism set outside the kiln body to obtain a suitable environment in the kiln body A control module; the adjustment mechanism includes a temperature adjustment module and a humidity adjustment module, wherein the temperature adjustment module is used for adjustment when the temperature is unbalanced; the humidity adjustment module is used for adjustment when the humidity is unbalanced.

[0043] The kiln body is sequentially provided with an insulation layer 3, a base frame layer 2 and a protective layer 1 from the inside to the outside, and a number of air nozzles 4 for temperature and humidity adjustment are arranged at the insulation layer 3, and the air nozzles 4 and An air pipe 11 is provided between the pedestal layer 2 and the protective layer 1, and the air p...

Embodiment 3

[0050] Embodiment 3: The difference between it and Embodiment 1 or 2 is: an intelligent whole-process temperature-controlled steam curing kiln using method:

[0051] 1) Put the pre-processed cement tower rod into the kiln body, then close the kiln door of the kiln body, and obtain internal environmental data through temperature and humidity sensors;

[0052] 2) According to the obtained internal environment data, the control module makes targeted adjustments, so as to ensure that each part of the cement tower pole can be maintained in a balanced manner, and avoid the maintenance caused by global supplementation due to the lack of water vapor in a certain place during the overall operation The phenomenon of time growth;

[0053] 3) First use steam heating to control the temperature at 75-85°C for 5-10 hours, then gradually slow down the amount of steam in the boiler, and pass the steam through the water vapor filter module to filter out the water vapor in it, and reduce it by 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com