Water-based sound-proof damping coating and preparation method thereof

A damping coating, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of not taking into account the performance of vibration and noise reduction, high damping, etc., to achieve excellent vibration and noise reduction effect, comprehensive performance improvement, restraint Vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0041] Take 10 parts of water and 0.2 parts of wetting and dispersing agent, stir and mix evenly, add 10 parts of talc powder and 5 parts of calcium carbonate under high-speed dispersion conditions, and prepare an inorganic filler water dispersion slurry.

[0042] Under high-speed dispersion conditions, polymer emulsion A and polymer emulsion B (see Table 1 for the type, dosage and glass transition temperature of the emulsion) were added to the inorganic filler water dispersion slurry, and then 5 parts of aluminum hydroxide and 5 parts of zinc borate were added in sequence. Then add 30 parts of mica powder, 0.1 parts of reinforcing fiber, 0.2 parts of antifungal agent and 2 parts of defoamer, and finally add 0.5 parts of thickener to adjust the consistency, and then the water-based sound insulation and damping coating for vehicles can be prepared.

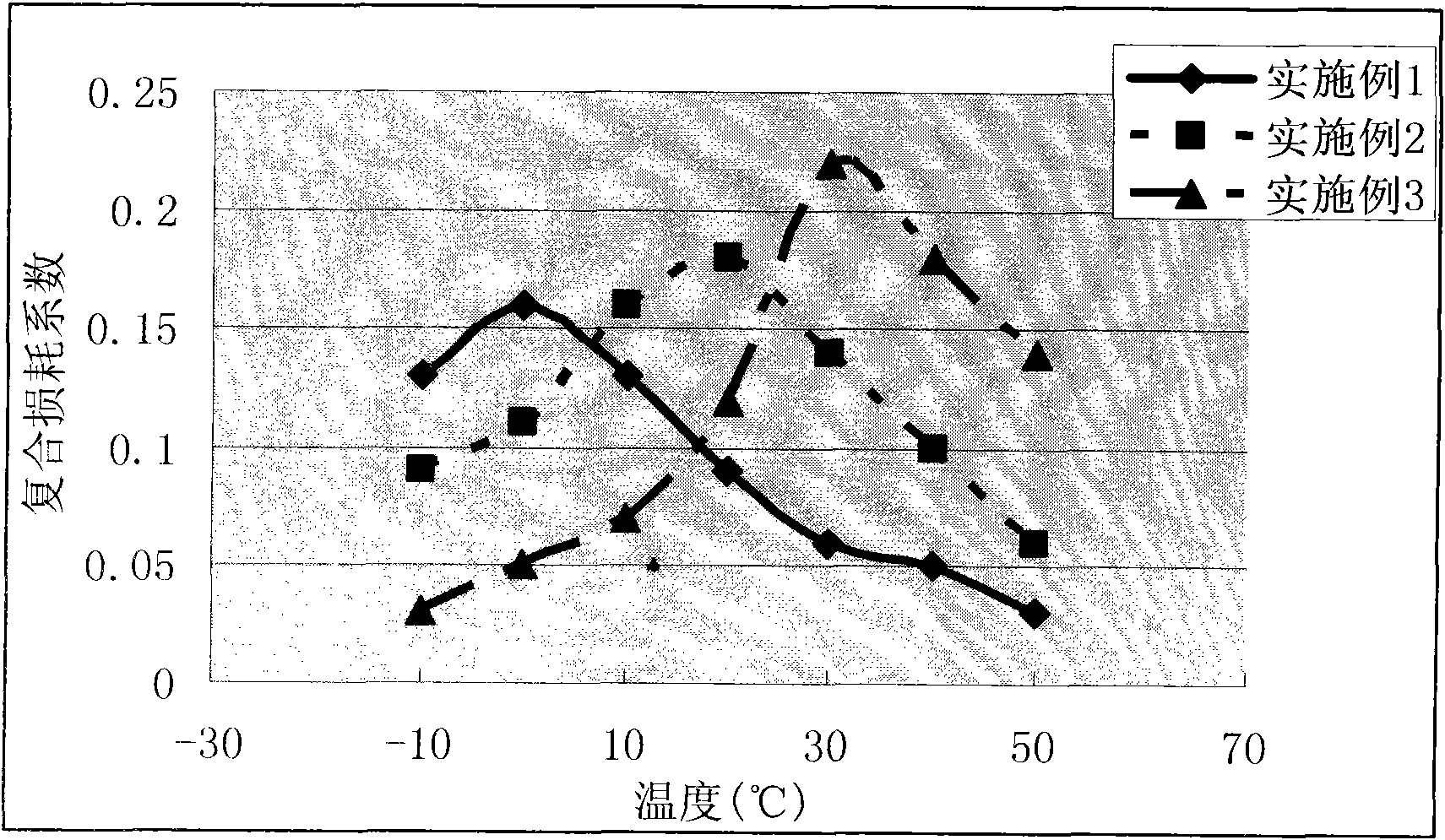

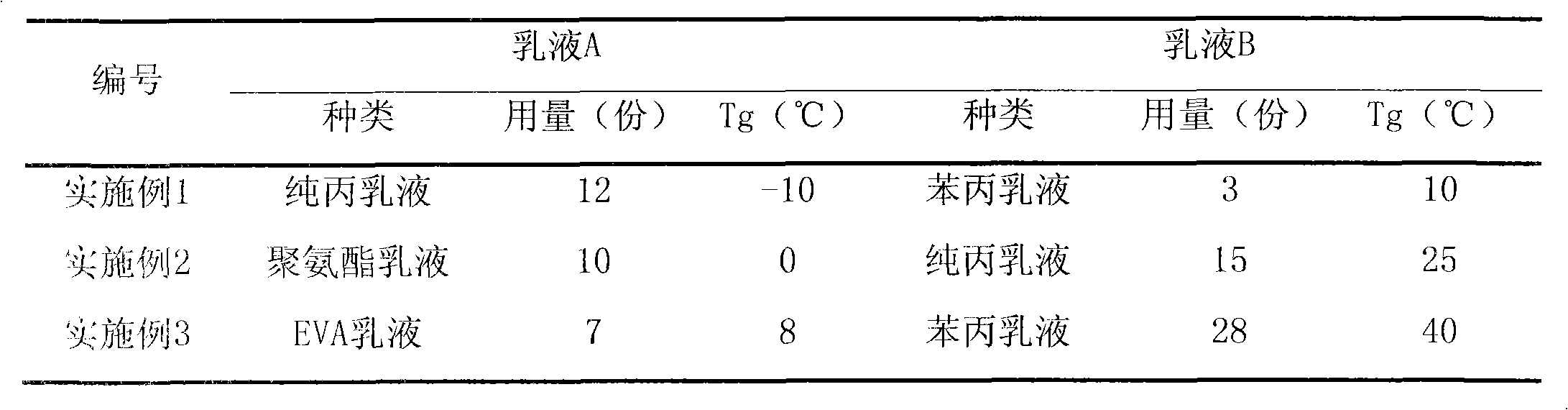

[0043] Table 1

[0044]

[0045] From figure 1 It can be seen from the figure that by adjusting the type and amount of polyme...

Embodiment 4-6

[0047]Take 15 parts of water and 0.5 parts of wetting and dispersing agent and stir and mix evenly, add filler A and filler B under high-speed dispersion conditions (see Table 2 for the type and amount of filler), and prepare water-dispersed slurry of inorganic filler.

[0048] Under high-speed dispersion conditions, add 10 parts of polyurethane emulsion and 15 parts of pure acrylic emulsion to the inorganic filler water dispersion slurry, then add 10 parts of magnesium hydroxide and 5 parts of aluminum phosphate in sequence, and then add filler C (see Table 2 for the type and amount of filler ), 0.1 part of reinforcing fiber, 0.2 part of antifungal agent and 2 parts of defoamer, and finally add 0.5 part of thickener to adjust the consistency, and the water-based sound-proof and damping coating for vehicles can be prepared.

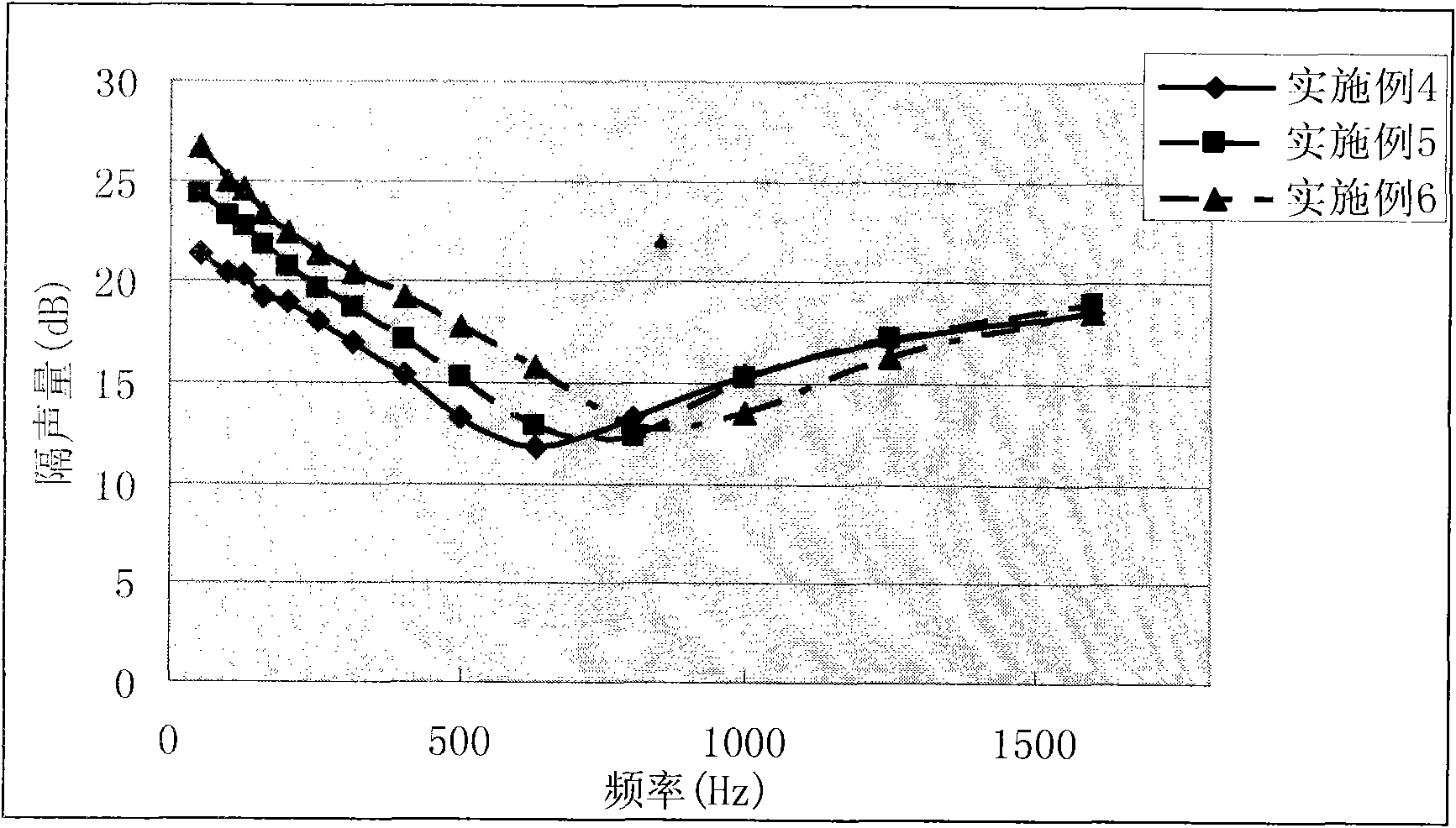

[0049] Table 2

[0050]

[0051] From figure 2 It can be seen from the figure that through the adjustment of inorganic fillers, water-based sound-in...

Embodiment 7-9

[0053] Take 20 parts of water and 0.8 parts of wetting and dispersing agent, stir and mix evenly, and add 15 parts of montmorillonite and 15 parts of calcium carbonate under high-speed dispersion conditions to prepare water-dispersed slurry of inorganic filler.

[0054] Under high-speed dispersion conditions, add 5 parts of vinyl acetate-ethylene copolymer emulsion and 25 parts of styrene-acrylic emulsion to the inorganic filler water dispersion slurry, and then add flame retardant A and flame retardant B in sequence (see Table 3 for the type and amount of flame retardant ), then add 25 parts of mica powder, 0.1 part of reinforcing fiber, 0.2 part of antifungal agent and 2 parts of defoamer, and finally add 0.5 part of thickener to adjust the consistency, and then the water-based sound-proof and damping coating for vehicles can be prepared.

[0055] table 3

[0056]

[0057] Table 4

[0058]

[0059] Table 4 shows the flame retardant performance data of water-based soun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com