Superfine regeneration powder compound geopolymer cementing material

A geopolymer and recycled powder technology, which is applied in solid waste management, cement production, sustainable waste treatment, etc., can solve problems such as the inability to more effectively tap the utilization methods and potential technical value of recycled powder from construction waste. Achieve the effects of increasing value and use value, saving large investment, promoting circular economy, energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] 1. Preparation and performance test of highly active ultrafine recycled powder from waste bricks

[0030] First, the waste brick construction waste is cleaned by crushing, iron removal, mud removal, and sundry removal, and then the clean waste brick is broken into small particles, which are sent to the ultrafine grinding equipment for ultrafine grinding of the waste brick. The performance test of the prepared superfine waste brick recycled powder was carried out, and the test results are shown in Table 1. Among them, the ignition loss, sulfur trioxide content and free calcium oxide content refer to GB / T176; the stability test refers to GB / T1346; the specific surface area test refers to GB / T8074; the activity index refers to pulverized coal according to the method of GB / T17671 Ash activity index test was carried out. The performance test and analysis results show that the superfine waste brick recycled powder has a high specific surface area, high activity, good stabili...

Embodiment

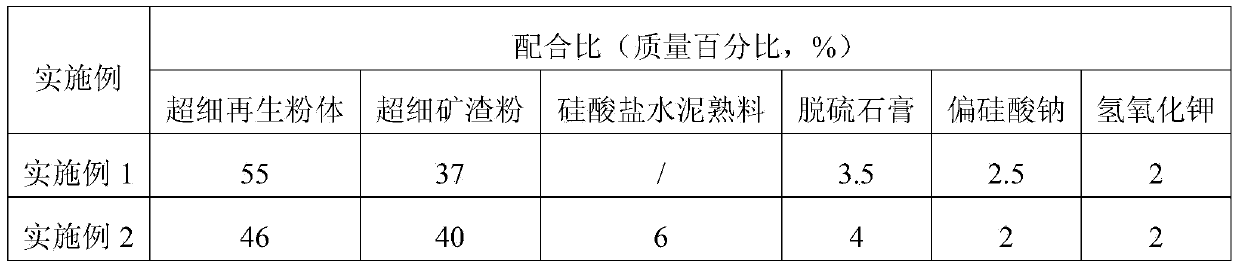

[0040] According to above-mentioned embodiment, prepared two kinds of composite geopolymer gelling materials respectively according to the mix ratio in the following table 3:

[0041] Table 3 Mixing ratio of composite geopolymer cementitious materials

[0042]

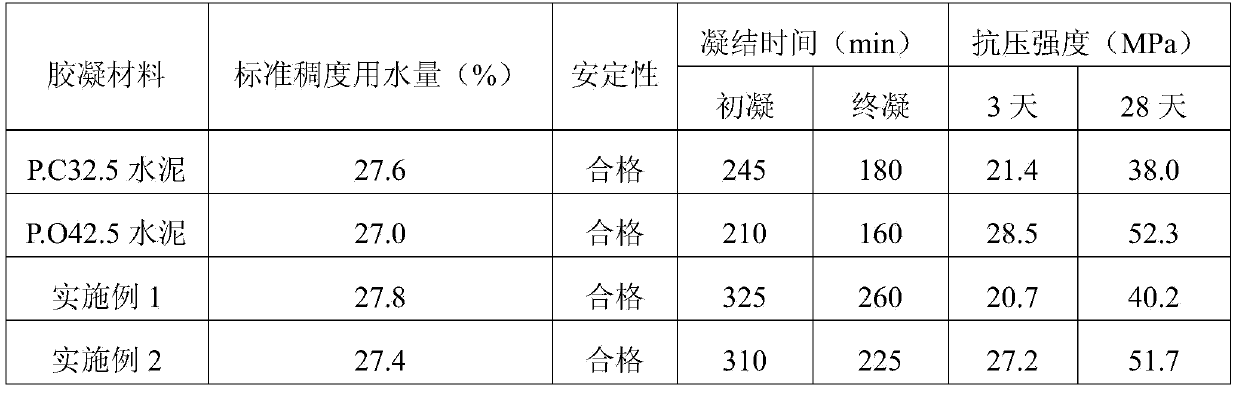

[0043] With reference to the cement test method stipulated in GB / T1346, the standard consistency water consumption, setting time and stability of the composite geopolymer cementitious materials of Examples 1 and 2 of the present invention and corresponding grades of cement were tested.

[0044] According to the cement mortar strength test method specified in GB / T17671-1999, the compressive strength of the composite geopolymer cementitious materials and corresponding grades of cement in Examples 1 and 2 of the present invention was tested.

[0045] The measurement results are shown in Table 4

[0046] Table 4 The performance of composite geopolymer cementitious material of the present invention and corresponding gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com