Bio-drying and dehumidifying coupled heat-pump flap tower type sludge drying process and system thereof

A technology of biological drying and sludge drying, applied in biological sludge treatment, dewatering/drying/concentrating sludge treatment, sludge treatment, etc., can solve the problems of high operating cost, burden, and long drying time. , to achieve the effect of improving energy efficiency and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

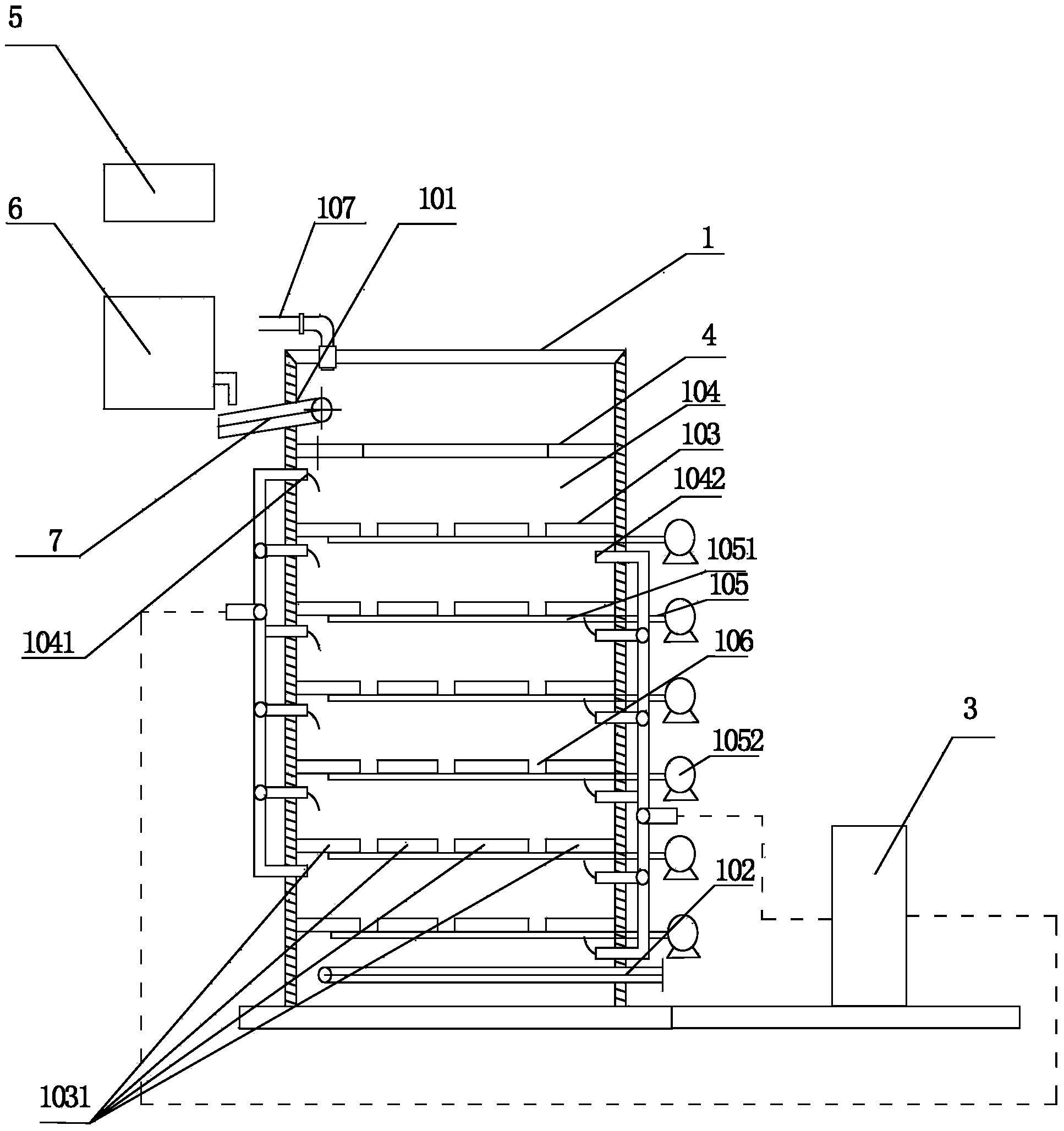

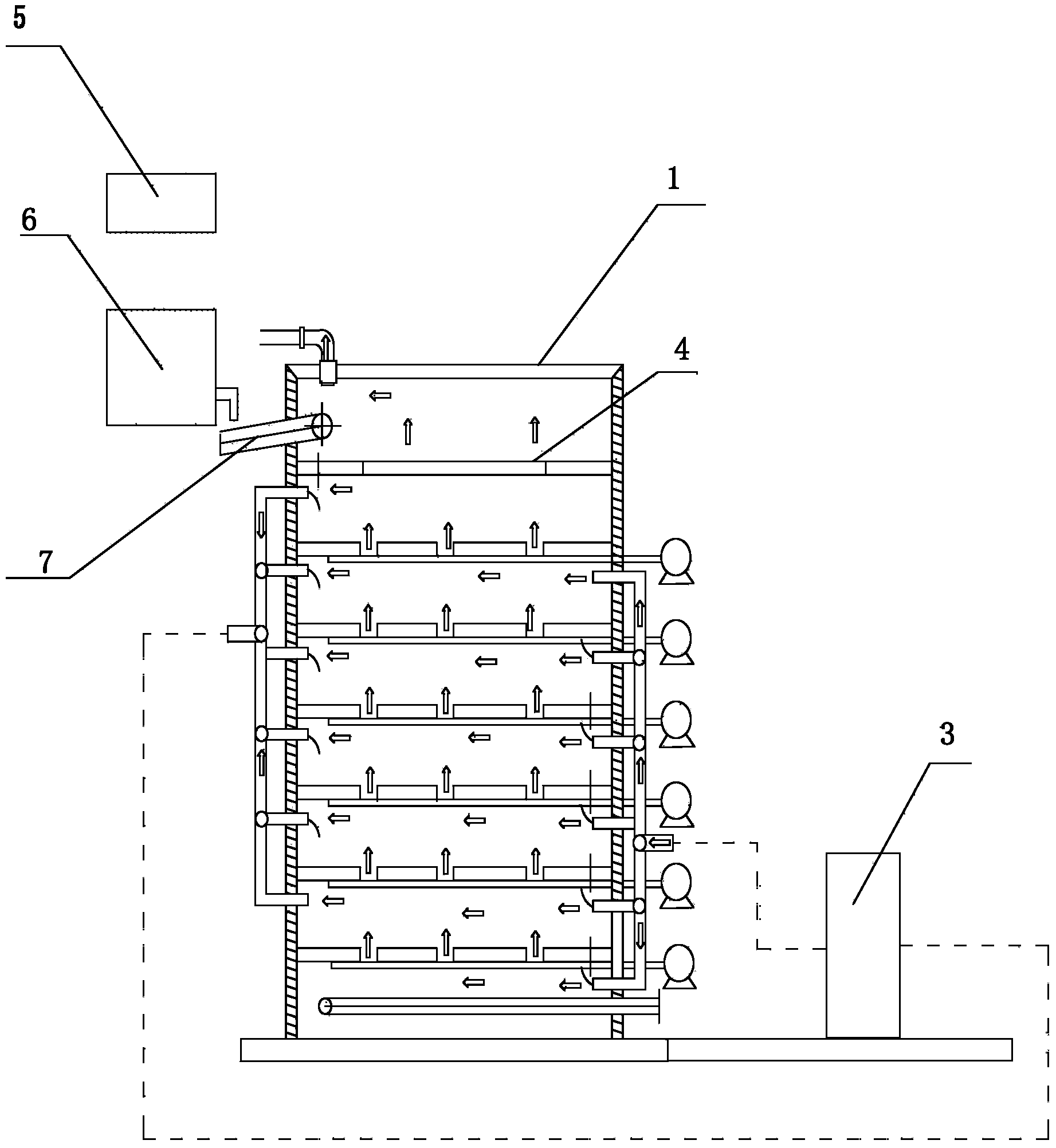

[0041] Such as figure 1 As shown, the water-containing sludge from the sewage treatment plant is taken. After dehydration, its water content is 79%, and its weight is 1000Kg. The organic matter accounts for 38% of the dry weight of the sludge. 50% of the finished clinker is dried with 1000Kg of sludge and 40kg of straw to obtain sludge with a moisture content of 64% and a total weight of 2040Kg. Then add 50Kg of a 10% aqueous solution of compound probiotic powder and stir evenly. The uniformly stirred sludge is added from the distributor 4 to the first layer of fermentation bin 104 of the vertical fermentation tower 1 through the raw material conveying mechanism. Type fermentation tower 1, dehumidification heat pump unit 3, dehumidification heat pump unit 3 supplies dry hot air at 45±10°C to the fermentation chamber 104, controls the temperature in the fermentation chamber 104 to be 50±5°C, and the humidity is 45% to 55%. The fresh air supply rate is 4-12 cubic meters per hou...

specific Embodiment 3

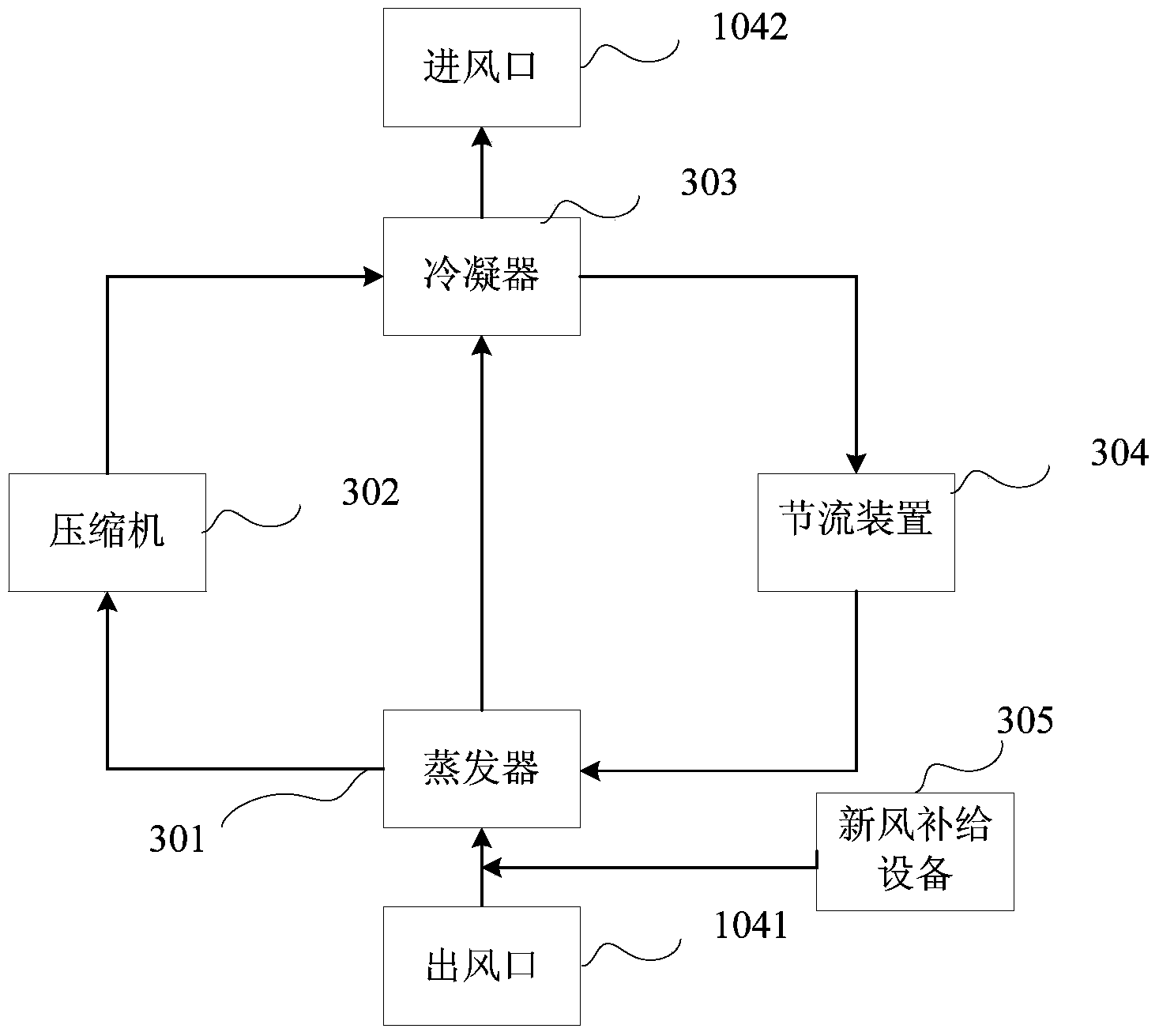

[0044] Such as Figure 1~4 As shown, a biological drying coupling dehumidification heat pump unit flap tower sludge drying system includes a vertical fermentation tower 1, the top of the vertical fermentation tower 1 is provided with a feed port 101, and the bottom is provided with a finished product The output mechanism 102 is provided with a multi-layer fermentation chamber 104 formed by several layers of flap structures 103 from top to bottom inside the vertical fermentation tower 1, and the number of layers of the flap structures 103 is 3 to 10 layers. It is preferably 4 to 5 floors. In addition, it also includes a dehumidification heat pump unit 3 composed of an evaporator 301, a compressor 302, a condenser 303 and a throttling device 304 connected end to end. An air outlet 1041 communicated with the evaporator 301, and an air inlet 1042 communicated with the condenser 303 is provided on the other side of the fermentation chamber 104 to form a dehumidification circuit. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com