Method for preparing multi-color long afterglow water borne luminescent coatings

A luminescent paint and long afterglow technology, which is applied in the fields of chemical materials and light industry, can solve problems such as weak adhesion, uneven brightness, poor water resistance, and poor wear resistance, and achieve long luminescence time, good comprehensive performance, and easy construction. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

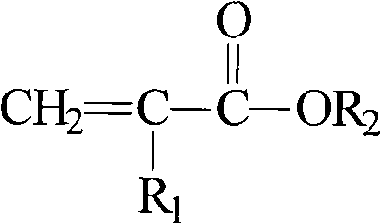

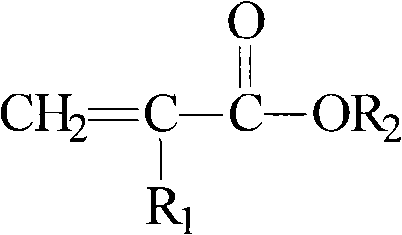

Method used

Image

Examples

Embodiment 1

[0041] Dissolve 5 g of sodium lauryl sulfate (emulsifier) and 3 mL of OP-10 in 100 mL of water, and then transfer them to a three-necked flask. After dissolving 0.5 g of ammonium persulfate with 50 mL of water, it was added to the above-mentioned three-necked flask, stirred with a mechanical stirrer, and heated. Mix three kinds of monomers, including 100mL of methyl methacrylate, 100mL of butyl acrylate and 10mL of methacrylic acid. Use), join in the above-mentioned three-necked flask, the reaction temperature is constant, and the reaction time is 20min. The remaining mixed monomers were added dropwise to the reaction solution in the three-necked flask with a dropping funnel, and then the initiator solution (aqueous solution of ammonium persulfate) was added dropwise. The reaction temperature when the initiator solution was added dropwise was 70°C. After the dropwise addition was completed, the reaction was continued for 30 min.

Embodiment 2

[0043] Dissolve 8g of sodium lauryl sulfate (emulsifier) and 2mL of OP-10 in 120mL of water, and then transfer them to a three-necked flask. After dissolving 0.8 g of dibenzoyl peroxide with 50 mL of water, it was added to the above-mentioned three-necked flask, stirred with a mechanical stirrer, and heated. Mix three kinds of monomers, including 150mL of nonyl acrylate, 90mL of butyl methacrylate and 10mL of acrylic acid. When the temperature of the solution in the three-necked flask rises to 80°C, take 20mL of mixed monomers (the remaining mixed monomers are for use) , added in the above-mentioned three-necked flask, the reaction temperature was constant, and the reaction time was 20min. The remaining mixed monomers were added dropwise to the reaction solution in the three-necked flask with a dropping funnel, and then the initiator solution (aqueous solution of dibenzoyl peroxide) was added dropwise. The reaction temperature when the initiator solution was added dropwise w...

Embodiment 3

[0045] Dissolve 10 g of sodium lauryl sulfate (emulsifier) and 5 mL of OP-10 in 150 mL of water, and then transfer them to a three-necked flask. After dissolving 1.0 g of azobisisobutyronitrile with 50 mL of water, it was added to the above-mentioned three-necked flask, stirred with a mechanical stirrer, and heated. Mix three kinds of monomers, including 120 mL of methyl methacrylate, 100 mL of butyl methacrylate and 6 mL of methacrylic acid. When the temperature of the solution in the three-necked flask rises to 100° C., take 40 mL of the mixed monomers (the remaining Body stand-by), join in the above-mentioned three-necked flask, the reaction temperature is constant, and the reaction time is 20min. The remaining mixed monomers were added dropwise to the reaction solution in the three-necked flask with a dropping funnel, and then the initiator solution (azobisisobutyronitrile aqueous solution) was added dropwise. The reaction temperature when the initiator solution was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com