Cu-Sn-Zn-S semiconductor material with adjustable forbidden band width and preparation method thereof

A technology of cu-sn-zn-s and bandgap width, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., to achieve stable properties, high environmental friendliness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of preparation method of the Cu-Sn-Zn-S semiconductor nanoparticle of adjustable bandgap width, the steps are as follows:

[0030] 1) The amount of material taken by weighing is 0.2 mmol of cupric chloride, 0.1 mmol of stannous chloride and 0.7 mmol of zinc chloride, dissolved in 50 milliliters of absolute ethanol, adding 2 mmol of thiourea, and ultrasonically making it dispersion. The obtained solution was distilled off ethanol at 50° C. by a rotary evaporator to obtain a precursor.

[0031] 2) The precursor is dispersed in 10 ml of oleylamine solution under ultrasonic conditions. Heat at 200°C for 10 minutes. After cooling to room temperature, absolute ethanol was added dropwise to precipitate the nanoparticles.

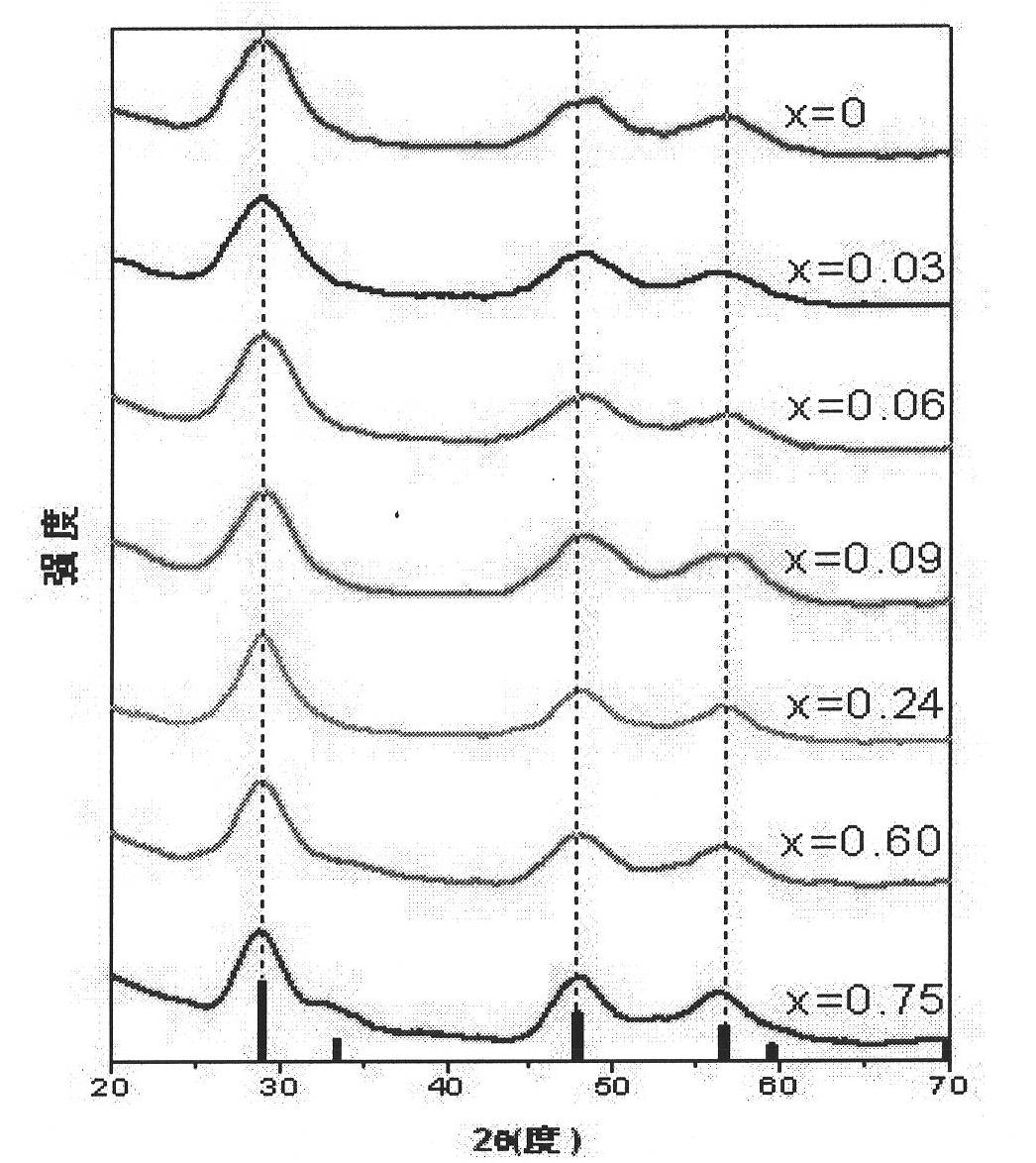

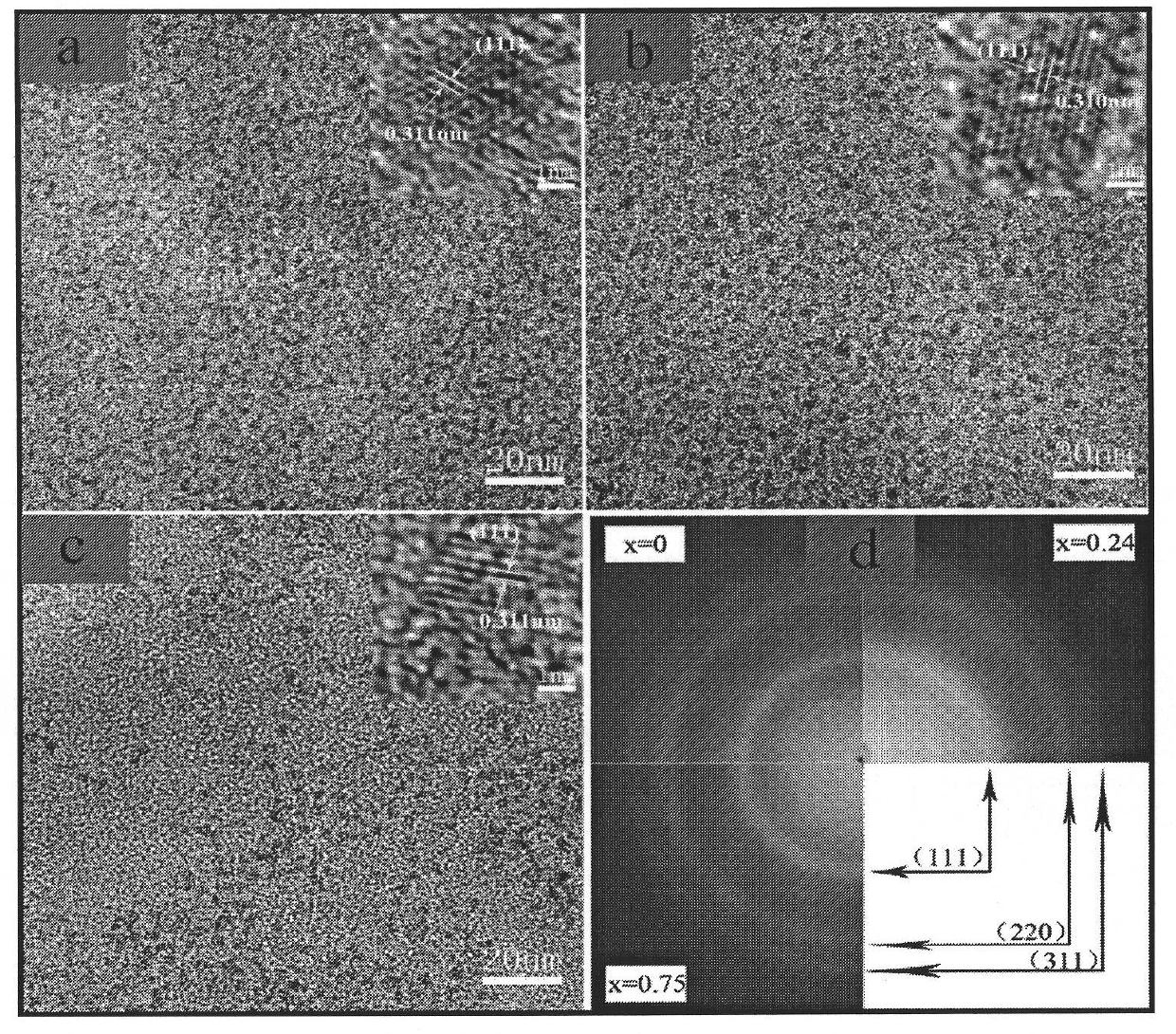

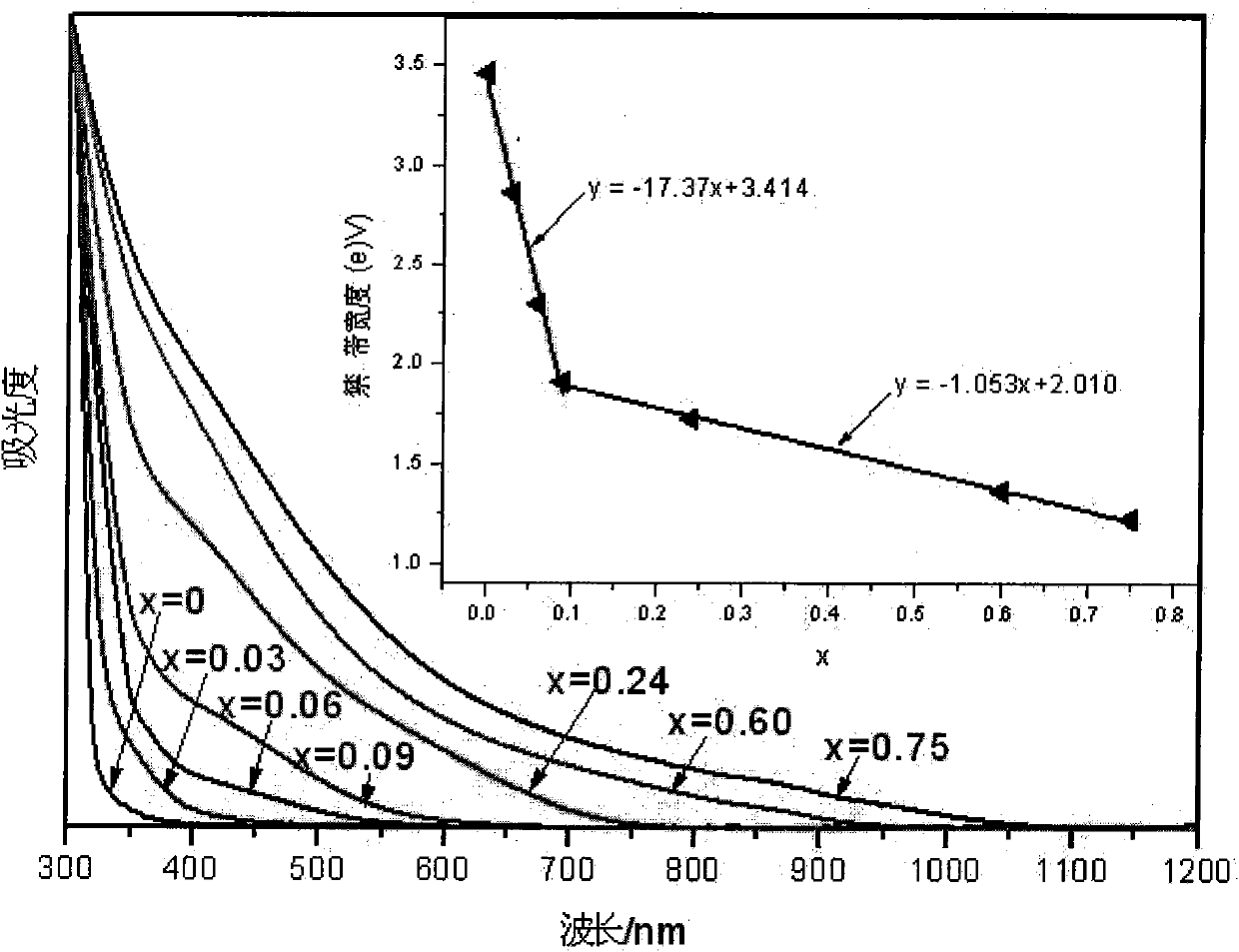

[0032] 3) The precipitate was washed several times with absolute ethanol, and redispersed in toluene to obtain monodisperse Cu 0.2 sn 0.1 Zn 0.7 S nanoparticles. The optical properties and bandgap of nanoparticles, such as image...

Embodiment 2

[0033] Embodiment 2: a kind of preparation method of the Cu-Sn-Zn-S semiconductor nanoparticle of adjustable bandgap width, the steps are as follows:

[0034] 1) The amount of material taken by weighing is 0.2 mmol of cupric chloride, 0.1 mmol of stannous chloride and 0.7 mmol of zinc chloride, dissolved in 20 milliliters of ethylene glycol, adding 2 mmol of thiourea, and ultrasonically dispersion.

[0035] 2) Add 5 ml of oleylamine, stir and heat at 200° C. for 10 minutes. After cooling to room temperature, the precipitate was collected.

[0036] 3) The precipitate was washed several times with absolute ethanol, and redispersed in toluene to obtain monodisperse Cu 0.2 sn 0.1 Zn 0.7 S nanoparticles.

Embodiment 3

[0037] Embodiment 3: a kind of preparation method of the Cu-Sn-Zn-S semiconductor nanoparticle of adjustable bandgap width, the steps are as follows:

[0038] 1) The amount of material taken by weighing is 0.2 mmol of cupric chloride, 0.1 mmol of stannous chloride and 0.7 mmol of zinc chloride, dissolved in 520 milliliters of ethylene glycol, adding 2 mmol of thiourea, and ultrasonically dispersion.

[0039] 2) Add 5 ml of oleylamine and 20 ml of liquid paraffin, and heat at 200° C. for 10 minutes. After cooling to room temperature, the liquids were separated, the organic phase was diluted with n-hexane, and absolute ethanol was added dropwise to precipitate the nanoparticles.

[0040] 3) The precipitate was washed several times with absolute ethanol, and redispersed in toluene to obtain monodisperse Cu 0.2 sn 0.1 Zn 0.7 S nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com