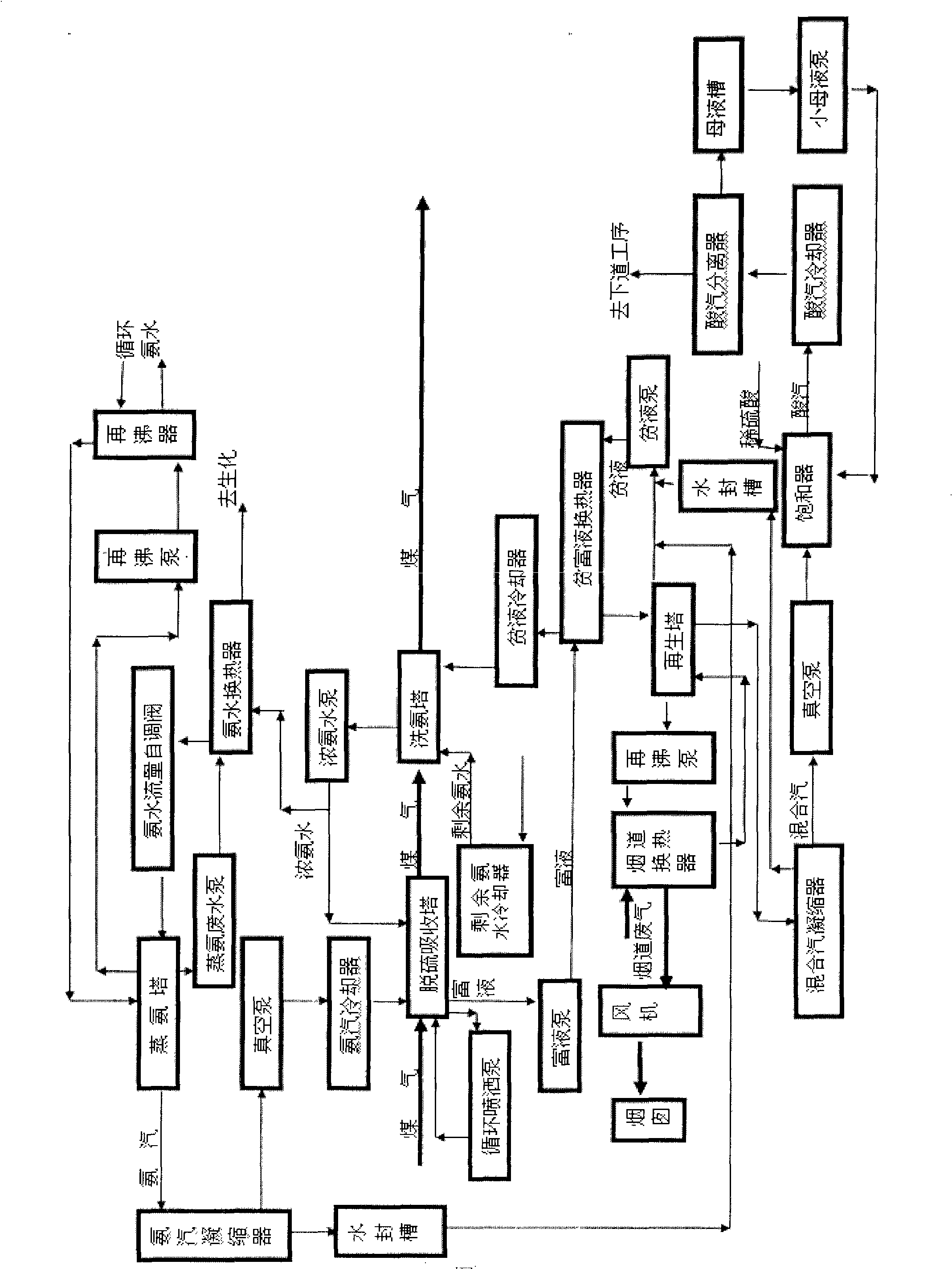

Desulphurization process by vacuum ammonia method

A vacuum and ammonia process technology, applied in the petroleum industry, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of complex process, low removal efficiency, high process energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

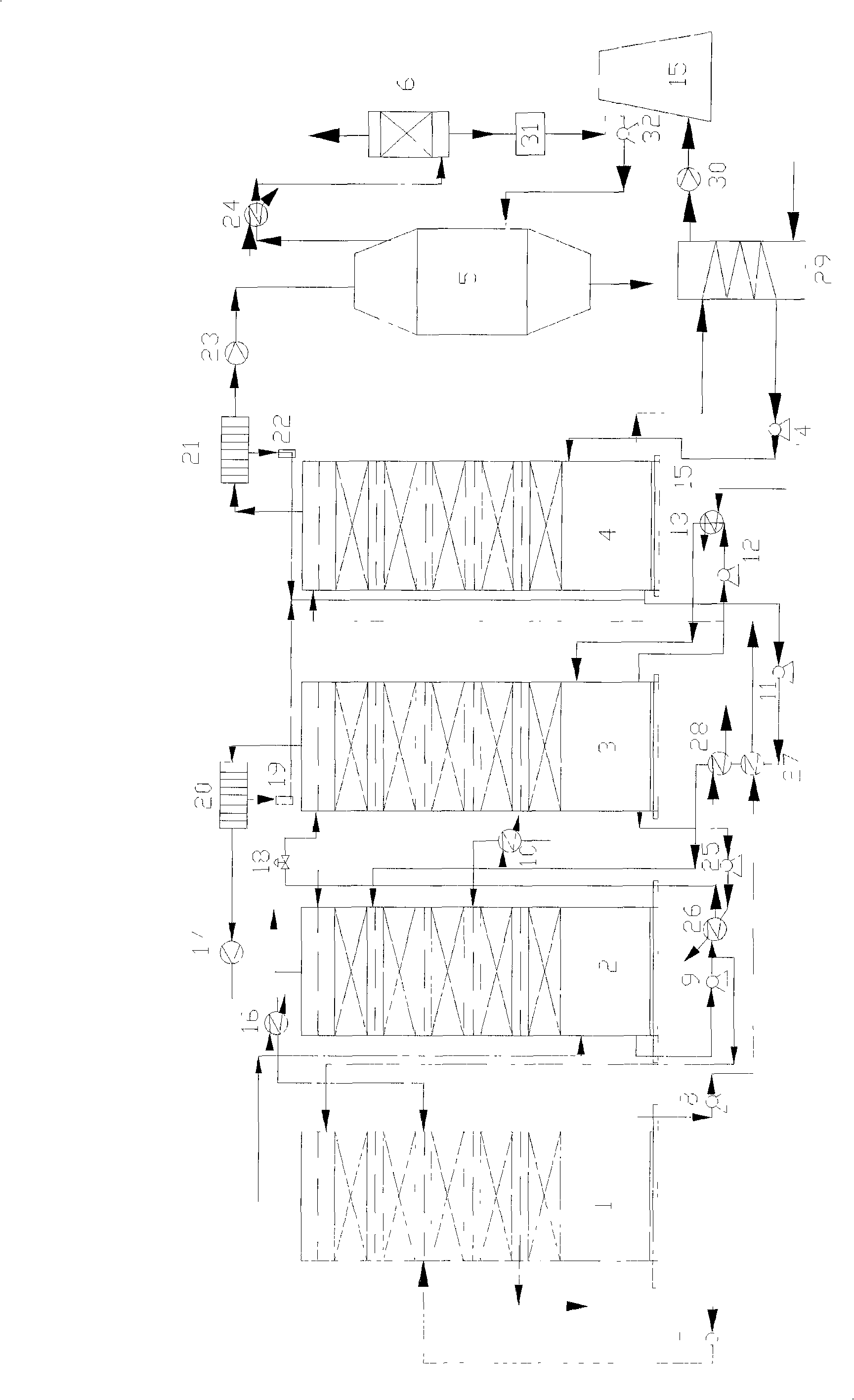

[0026] figure 2 Middle: 1. Desulfurization absorption tower, 2. Ammonia washing tower, 3. Ammonia distillation tower, 4. Regeneration tower, 5. Saturator, 6. Acid vapor separator, 7. Circulating spray pump, 8. Rich liquid pump, 9 , concentrated ammonia water pump, 10, residual ammonia water cooler, 11, greedy liquid pump, 12, reboil pump, 13, reboiler, 14, reboil pump, 15, chimney, 16, ammonia vapor cooler, 17, vacuum pump , 18. Ammonia water flow self-regulating valve, 19. Water seal tank, 20. Ammonia vapor condenser, 21. Mixed steam condenser, 22. Water seal tank, 23. Vacuum pump, 24. Acid vapor cooler, 25. Ammonia distillation wastewater pump, 26, ammonia water heat exchanger, 27, greedy rich liquid heat exchanger. 28. Liquid cooler, 29. Flue gas heat exchanger, 30 exhaust fan, 31. Mother liquor tank, 32. Small mother liquor pump

[0027] The patent of the present invention is implemented through the following specific steps: 70,000 m of gas is processed per hour 3 For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com