Identifying and automatic aligning system for coking furnace machinery furnace number

An automatic alignment and mechanical furnace technology, applied in coke ovens, control systems, vector control systems, etc., can solve problems such as inability to reflect whether the vehicle is aligned, red coke landing accidents, wrong furnace numbers, etc., and achieve market application The effect of broad prospect, improvement of operation efficiency and improvement of control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Coke pushing machine 25, coal loading car 26, coke blocking machine 27, and electric locomotive 28 are each composed of PLC programmable controller 30, Ethernet card 31, HMI human-machine interface 32, switch 33, Ethernet 34, wireless adapter 35, and wireless antenna 37 and body 40 constitute.

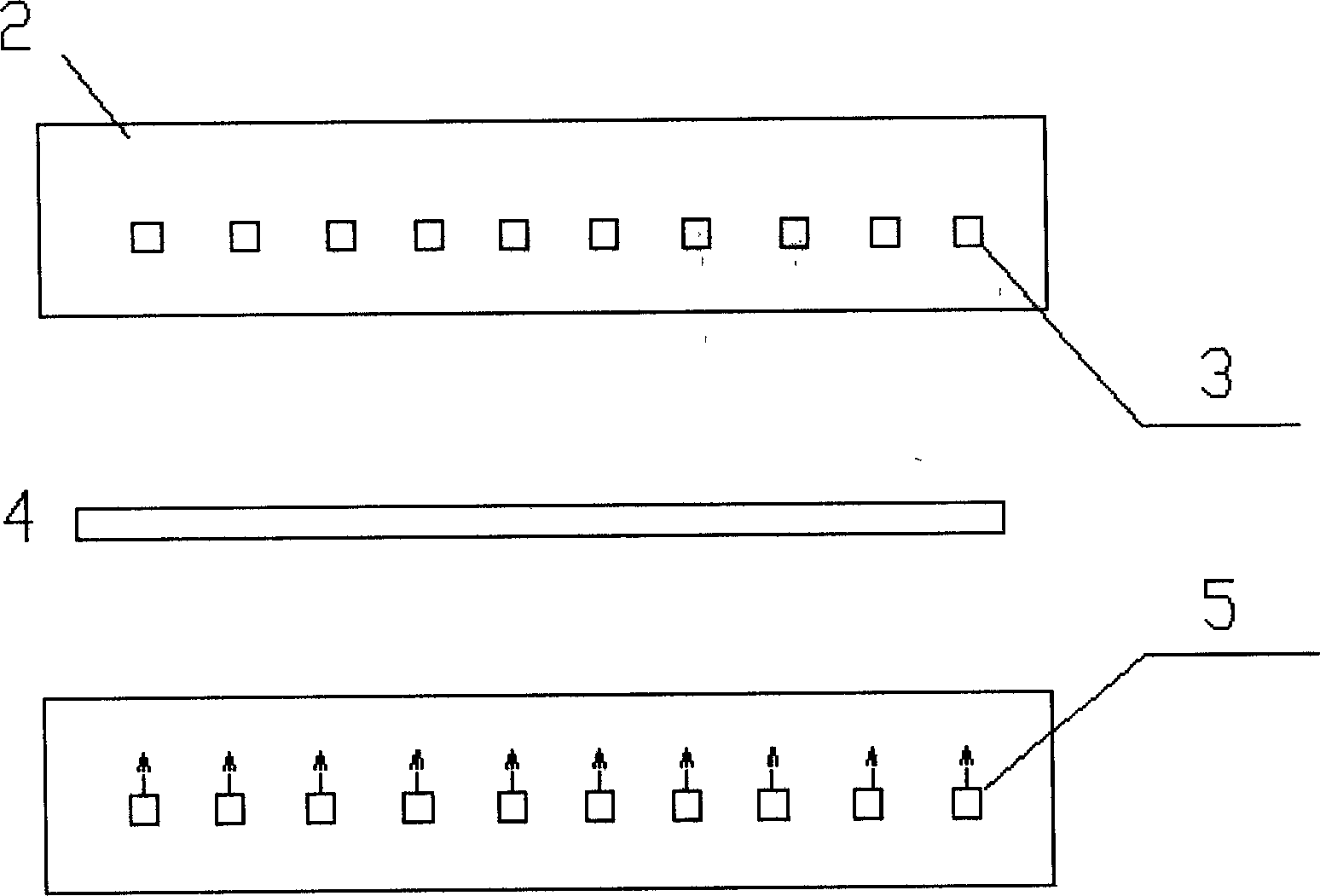

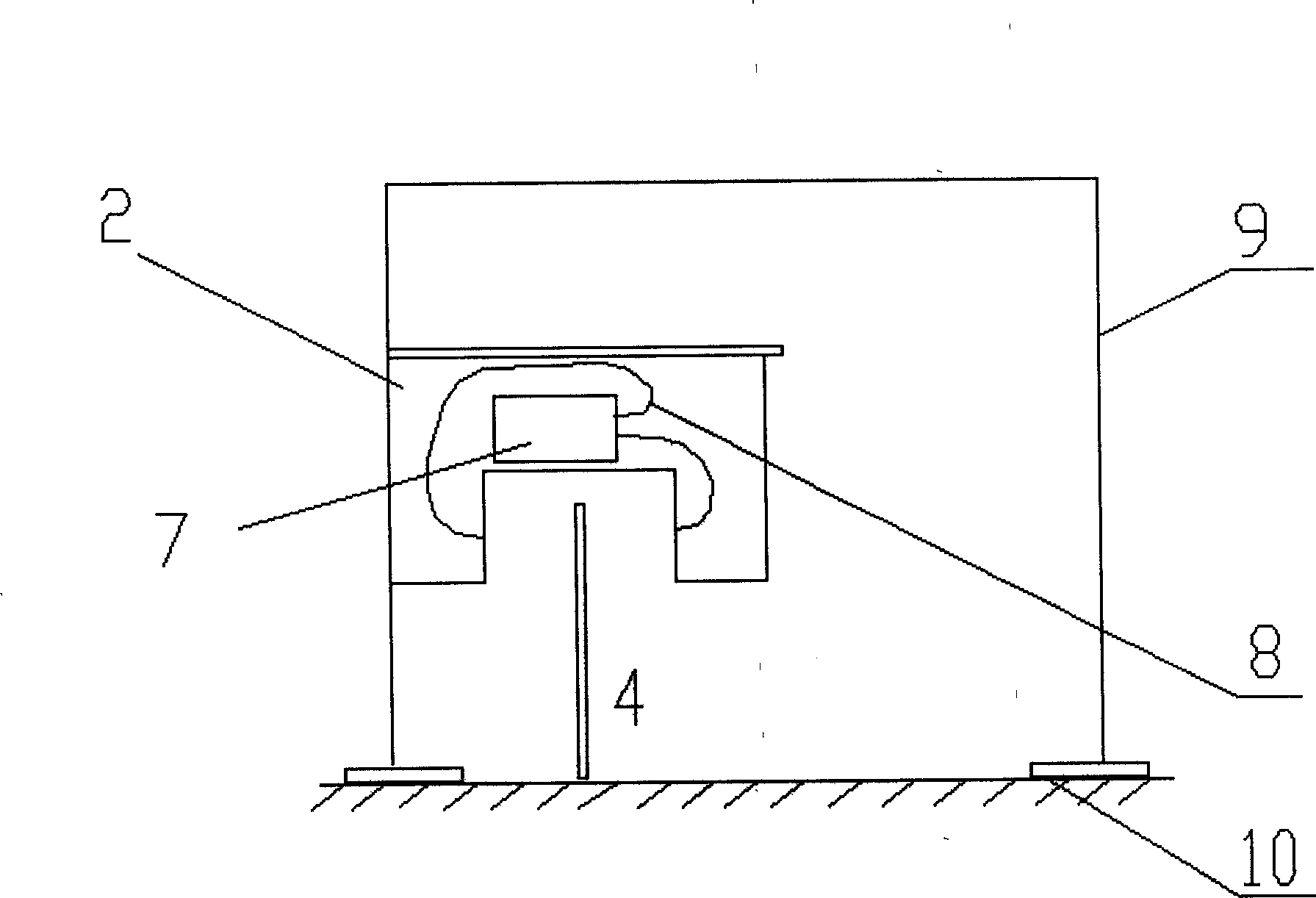

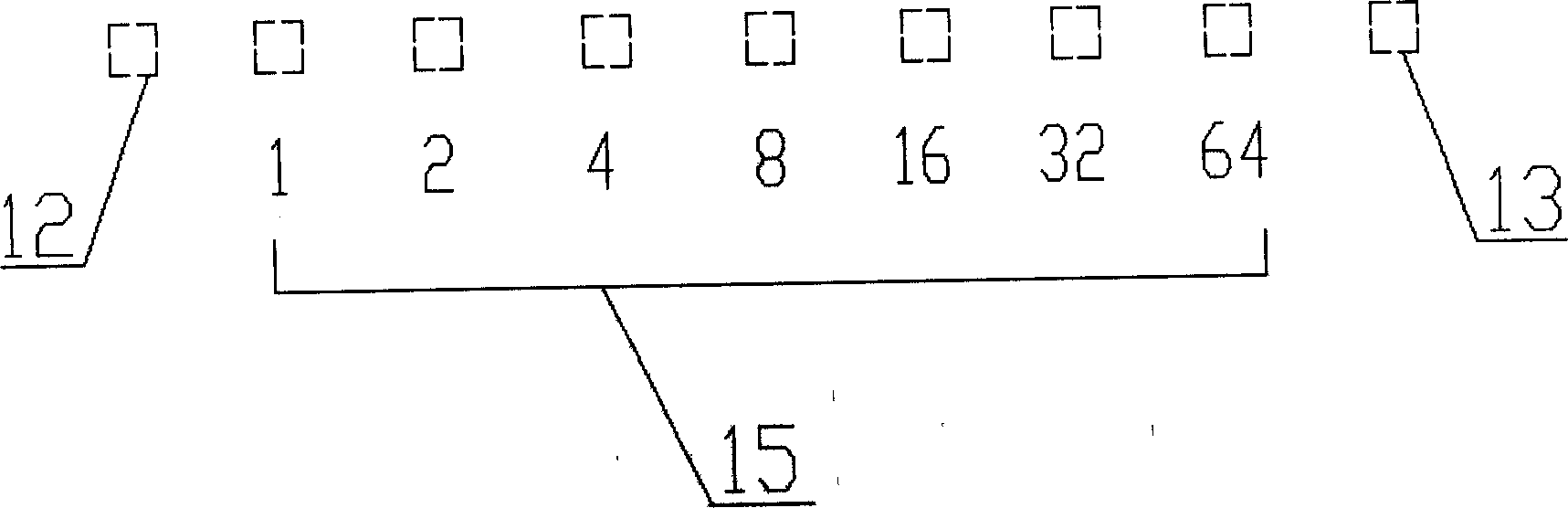

[0019] Furnace number identification system, the code plate 4 used for furnace number identification is coded according to the furnace number, using seven-digit binary code, with a start bit of 12, a check bit of 13, and a stop bit of 14, and the code plate 4 is placed corresponding to each furnace number On the track 10, there is a furnace number and a code disc 4; the code disc 4 corresponding to the furnace number is installed on the ground, and the code disc identification device 2 is installed on the vehicle. The code disc identification device 2 is composed of a receiving end 3 and a transmitting end 5, and a built-in The photoelectric switch 7 connected by the optical fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com