Method and device for coking by coke tar residue and blended coal

A coal blending coking and tar residue technology, applied in the field of waste oil residue treatment, can solve the problems of no long-term stable operation, low value-added utilization, fluctuations in coke quality, etc., to prevent sedimentation and stratification, improve fluidity, and reduce corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

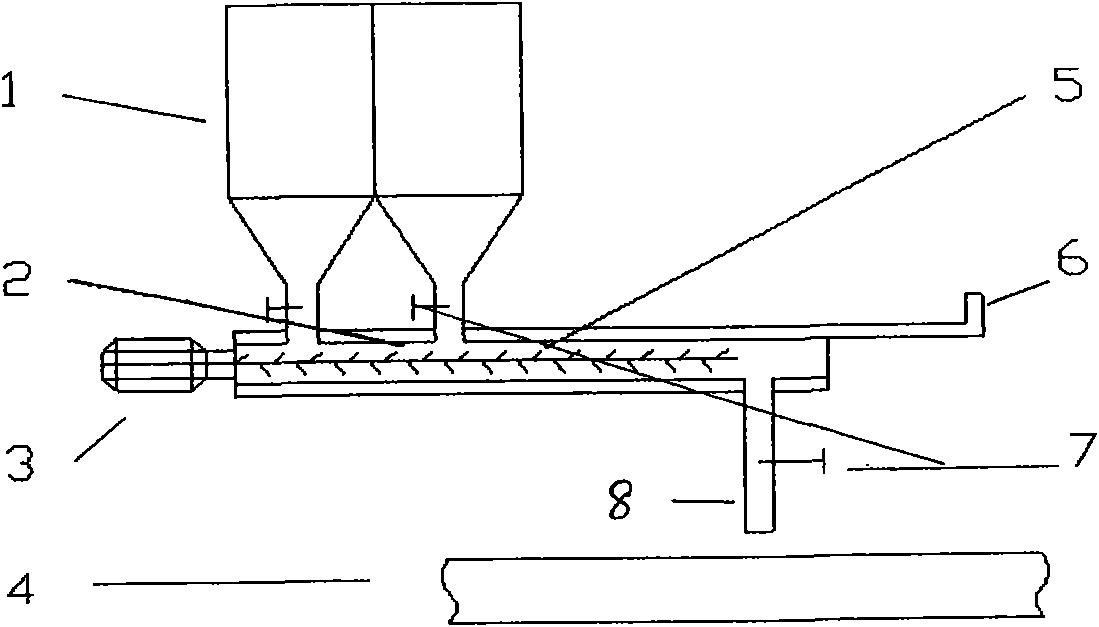

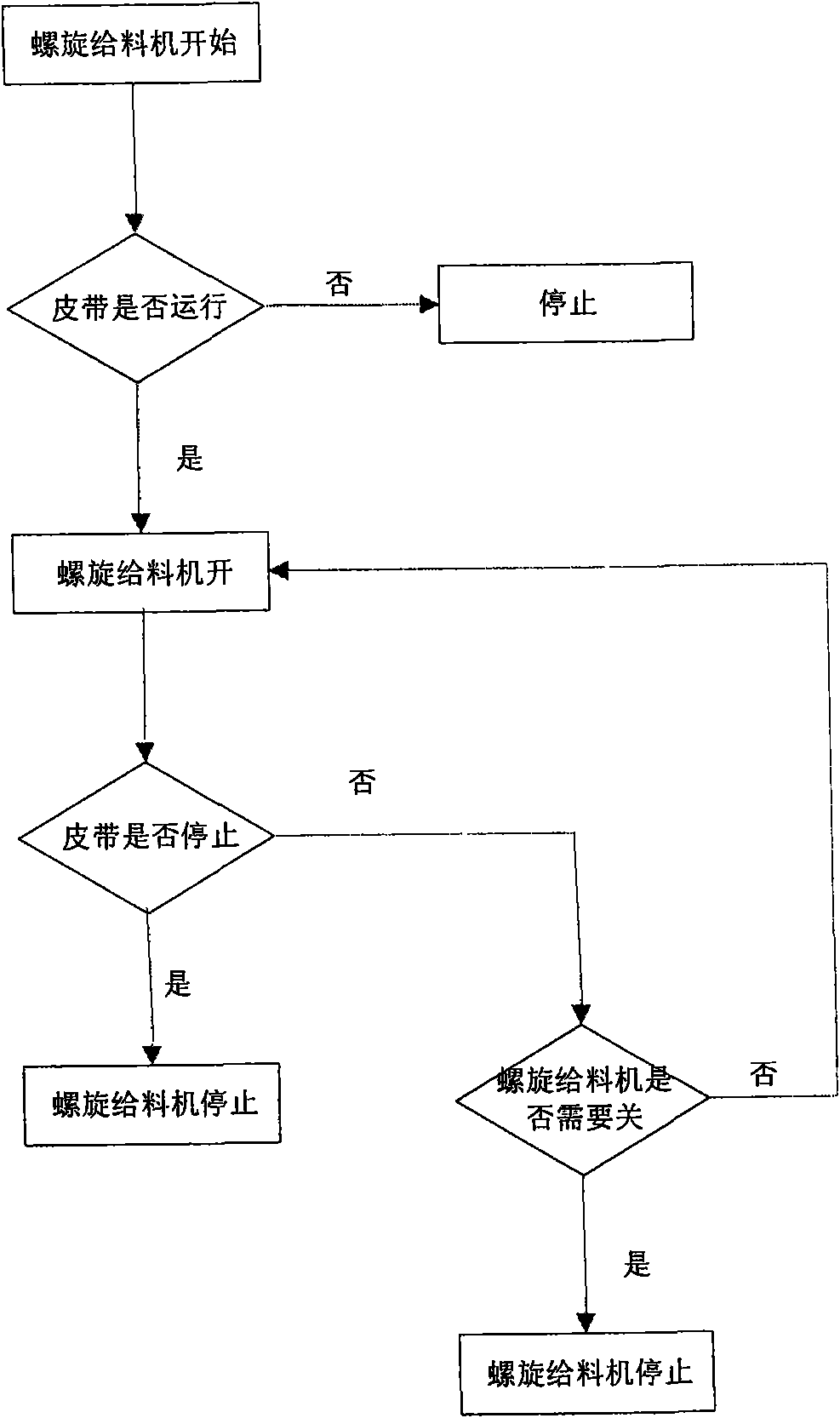

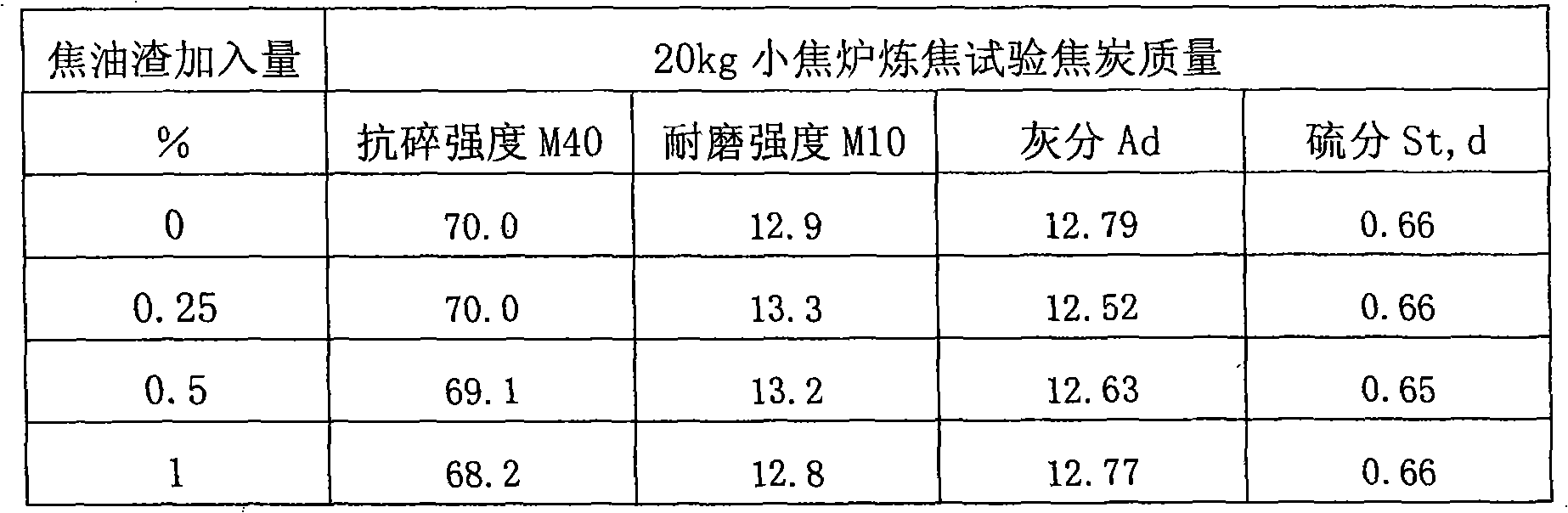

[0029] A method for blending tar residue with coal for coking, comprising the following steps: transporting tar residue through a tar residue tank to a sealed feeding tower, heating and transporting with steam, conveying materials through a screw feeder, and running through a screw feeding electric valve and a belt The chain control accurately adds the tar residue to the blended coal, so that the tar residue can be used reasonably. The above-mentioned steam is superheated steam, which maintains the temperature of the tar residue at 60-80°C, enhances the fluidity of the tar residue, and stabilizes the delivery effect. The above-mentioned transport of materials by the screw conveyor can control the flow rate of the tar residue relatively accurately, and can control the proportion of the tar residue at 0.3-0.5% of the coal blending weight. The above-mentioned screw feeding and belt interlocking control, the schematic diagram of screw feeding and belt interlocking control is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com