Process for treating coking waste water containing phenol and cyanogen by physical chemistry method and special device therefor

A treatment process and technology for cyanide wastewater, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of substandard solubility and high energy consumption for ammonia steaming, and achieve the treatment effect. Good, low operating cost, ensuring zero-emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

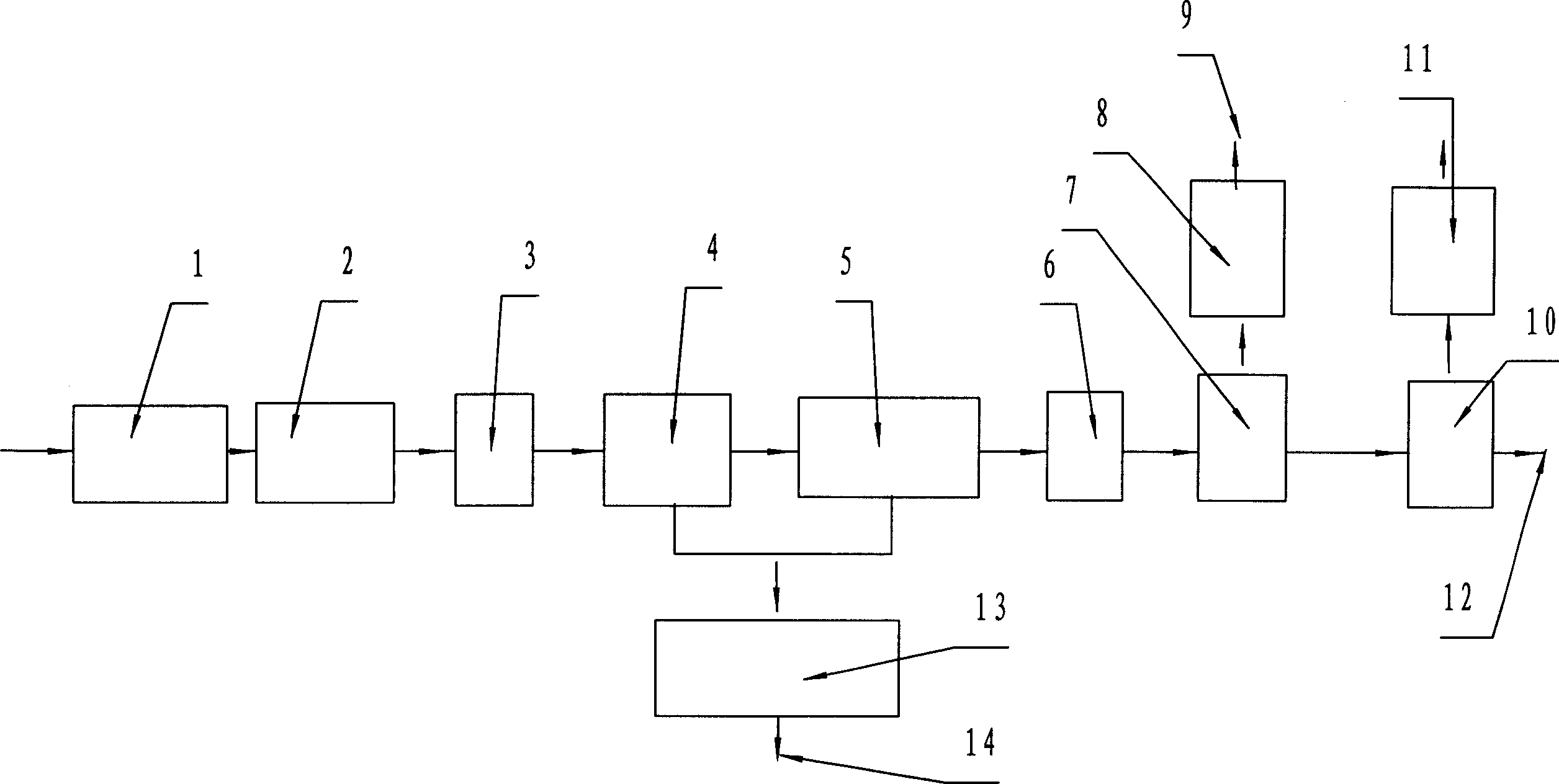

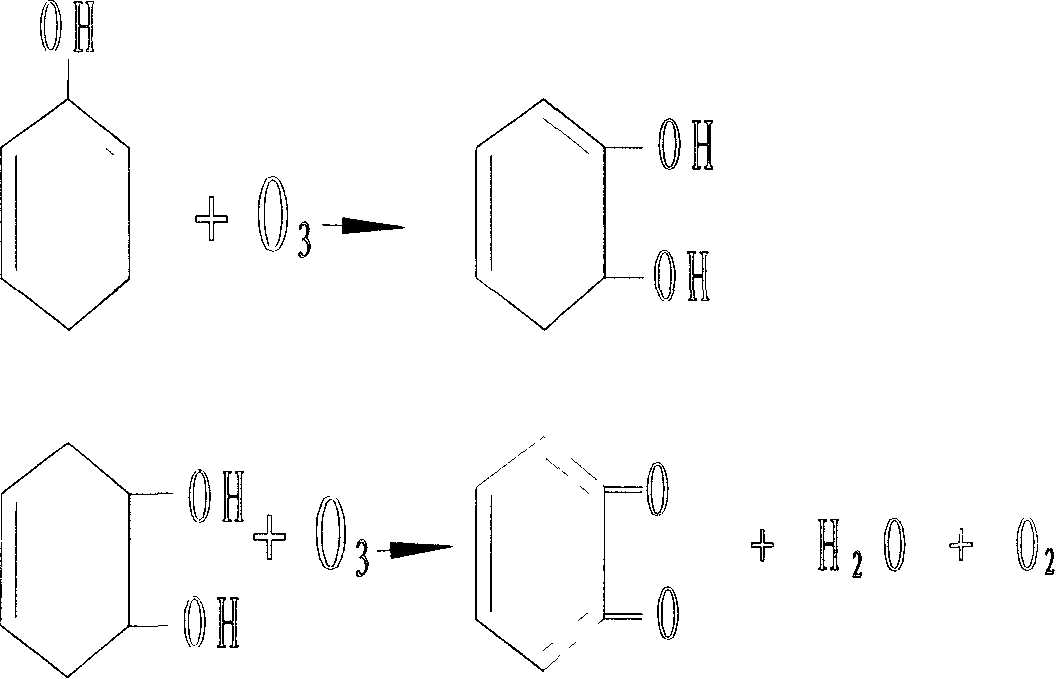

[0026] Example 1, a physicochemical coking phenol cyanide wastewater treatment process, the process flow is: air flotation deoiling → iron coagulation desulfurization and decyanation → coke adsorption and filtration to remove suspended sediment → desorption method to remove NH 3 -N→Ozone oxidation removes phenols and organic matter, and the treated wastewater is used as supplementary water for coal washing and coke quenching in coking plants.

[0027] The air flotation and deoiling process adopts an ejector air flotation and deoiling device, and the gas filling ratio is 7-8%.

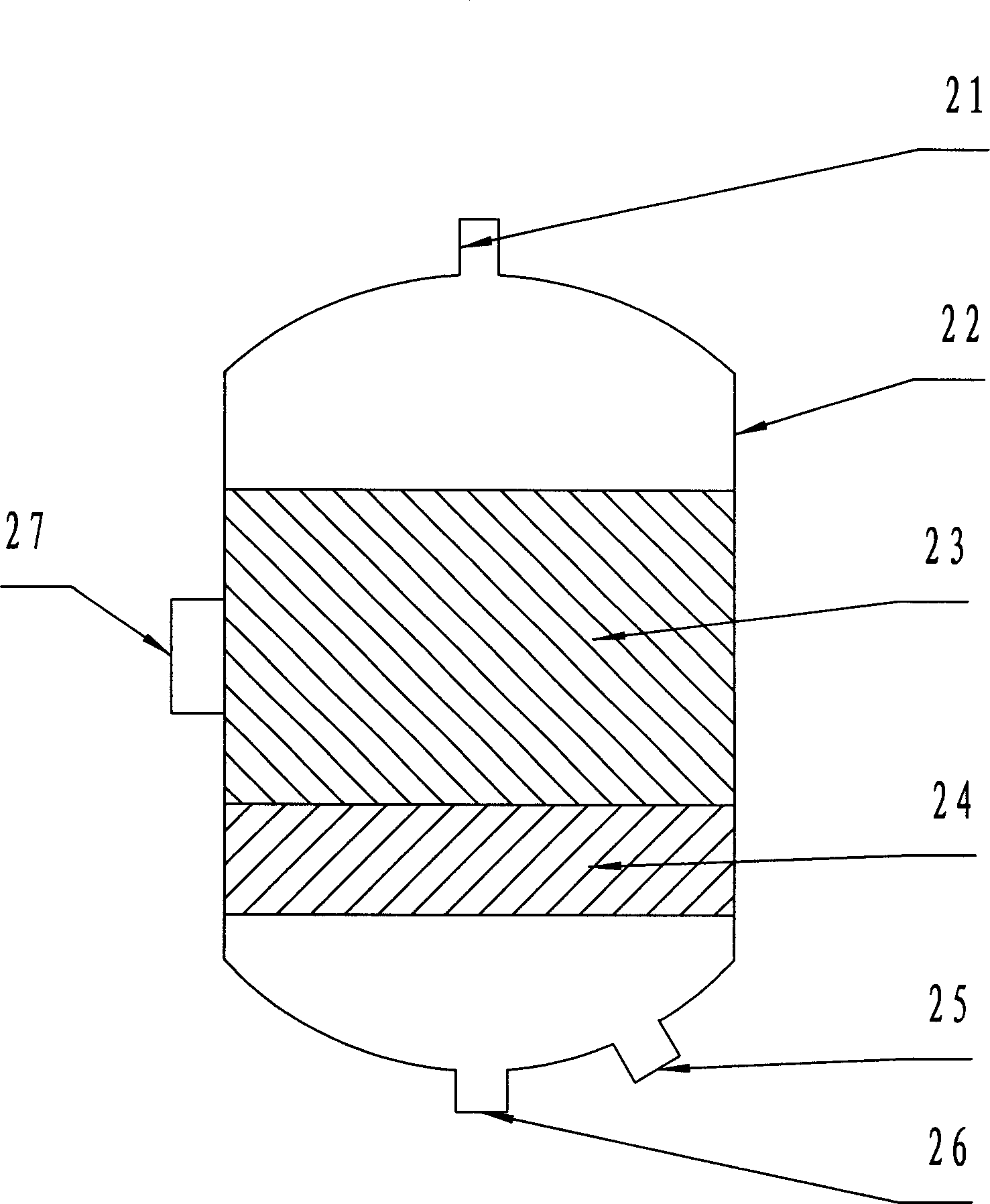

[0028] The ferrocoagulation desulfurization and decyanation process is carried out in a special reactor, in which Fe is obtained from elemental iron according to the micro-battery effect 2+ , thiocyanide and Fe 2+ The reaction produces FeS and Fe which are insoluble in water 2 [Fe(CN) 6 ]

[0029] Its main reaction is as follows:

[0030]

[0031]

[0032]

[0033]The reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com