Low-temperature coke oven flue waste gas cleaning technology and equipment thereof

A technology of coke oven flue and chemical equipment, applied in chemical instruments and methods, separation of dispersed particles, ammonium sulfate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

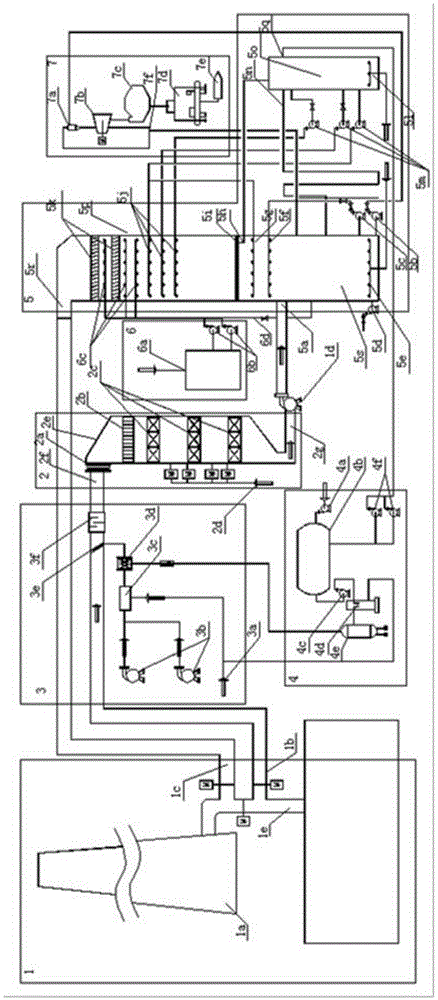

Image

Examples

Embodiment 1

[0070] A low-temperature coke oven flue gas cleaning process, the process includes a low-temperature denitrification process and an ammonia desulfurization process;

[0071] The specific steps are:

[0072] (1) Ammonia is mixed with hot air to form a mixed gas of ammonia and air;

[0073] (2) The coke oven flue gas is mixed evenly with the mixed gas of ammonia and air, and the catalyst catalyzes denitrification;

[0074] (3) The denitrified coke oven flue gas is sequentially desulfurized with the atomized ammonium sulfate secondary circulation fluid and the atomized ammonium sulfate primary circulation fluid and then discharged;

[0075] When using the atomized ammonium sulfate primary circulating fluid for desulfurization reaction, the denitrified coke oven flue gas is sprayed with the upper, middle and lower layers of the ammonium sulfate primary circulating fluid in sequence; the upper layer of the ammonium sulfate primary circulating fluid The pH value is 6, the pH value...

Embodiment 2

[0092] A low-temperature coke oven flue gas cleaning process, the process includes a low-temperature denitrification process and an ammonia desulfurization process;

[0093] The specific steps are:

[0094] (1) Ammonia is mixed with hot air to form a mixed gas of ammonia and air;

[0095](2) The coke oven flue gas is mixed evenly with the mixed gas of ammonia and air, and the catalyst catalyzes denitrification;

[0096] (3) The denitrified coke oven flue gas is sequentially desulfurized with the atomized ammonium sulfate secondary circulation fluid and the atomized ammonium sulfate primary circulation fluid and then discharged;

[0097] When using the atomized ammonium sulfate primary circulating fluid for desulfurization reaction, the denitrified coke oven flue gas is sprayed with the upper, middle and lower layers of the ammonium sulfate primary circulating fluid in sequence; the upper layer of the ammonium sulfate primary circulating fluid The pH value is 5.5, the pH valu...

Embodiment 3

[0115] A low-temperature coke oven flue gas cleaning process, the process includes a low-temperature denitrification process and an ammonia desulfurization process;

[0116] The specific steps are:

[0117] (1) Ammonia is mixed with hot air to form a mixed gas of ammonia and air;

[0118] (2) The coke oven flue gas is mixed evenly with the mixed gas of ammonia and air, and the catalyst catalyzes denitrification;

[0119] (3) The denitrified coke oven flue gas is sequentially desulfurized with the atomized ammonium sulfate secondary circulation fluid and the atomized ammonium sulfate primary circulation fluid and then discharged;

[0120] When using the atomized ammonium sulfate primary circulating fluid for desulfurization reaction, the denitrified coke oven flue gas is sprayed with the upper, middle and lower layers of the ammonium sulfate primary circulating fluid in sequence; the upper layer of the ammonium sulfate primary circulating fluid The pH value is 5.7, the pH val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com