Low-cost coking coal blending system

A coal blending system, low-cost technology, applied in coke oven, petroleum industry and other directions, can solve the problems of incomplete detection means, complex prediction system, difficult application and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

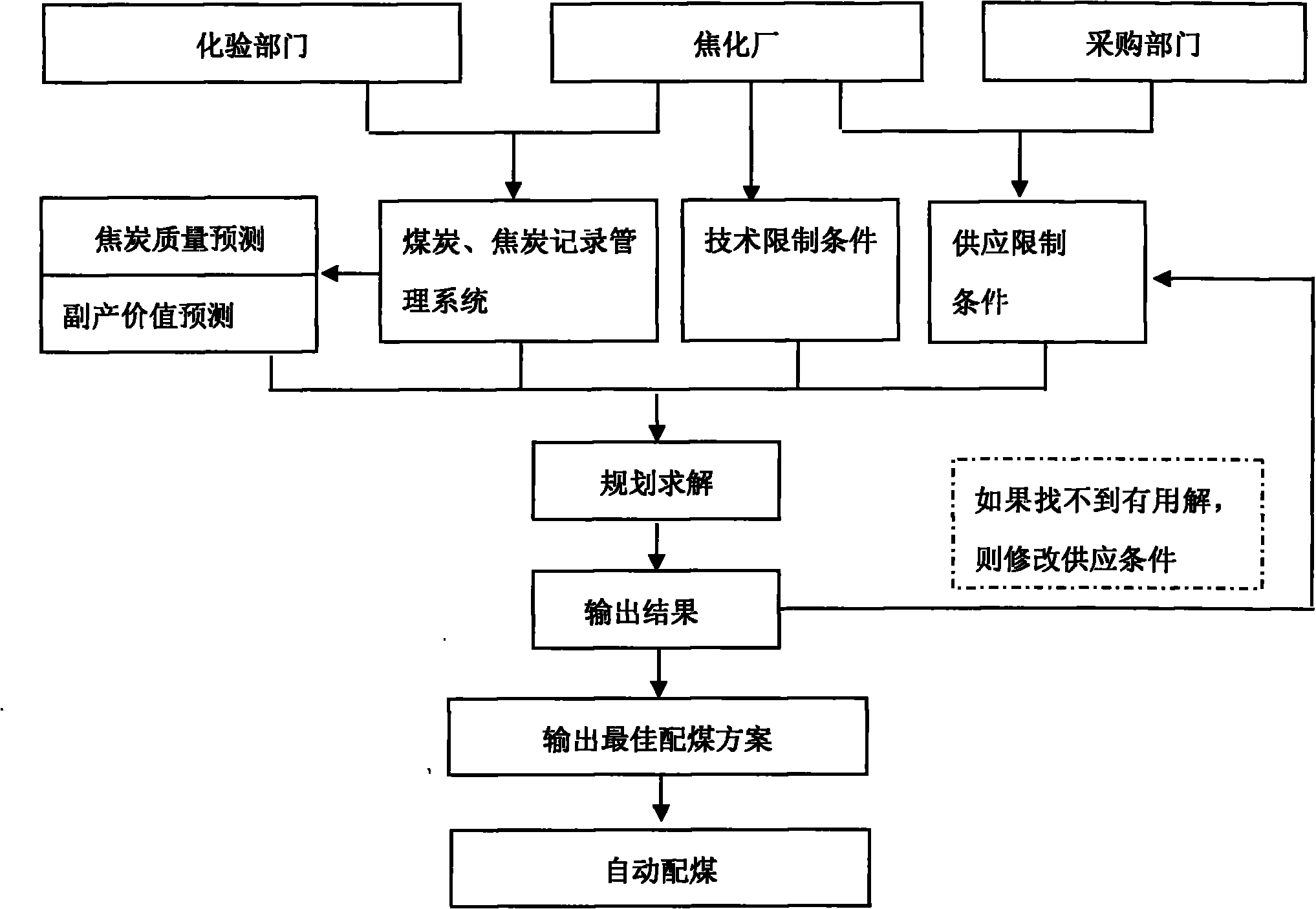

[0040] The invention closely integrates the established coal and coke characteristic record management module, coke quality prediction module, by-product value prediction module and optimized coal blending module through the server and the network, and updates in real time. It can be used in coal quality, coke quality prediction, coal net Under the constraints of price (coal price-by-product price), coal reserve and purchase, the method of planning and solving is used to automatically obtain the coal blending plan with the lowest net cost that meets the coke quality requirements and all technical, storage and purchase constraints. Low cost and accurate coal blending.

[0041] The present invention is realized through the following technical solutions:

[0042] 1. Establish a record management module for coal and coke characteristics

[0043] This module includes data collection and calculation of coal performance, production coal ratio, coke quality, and real-time collection of perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com