Chilli strip automatic production line

An automatic production line and hot strip technology, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of low production efficiency, worrying about hygienic quality, and high viscosity of seasonings, and achieve the effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

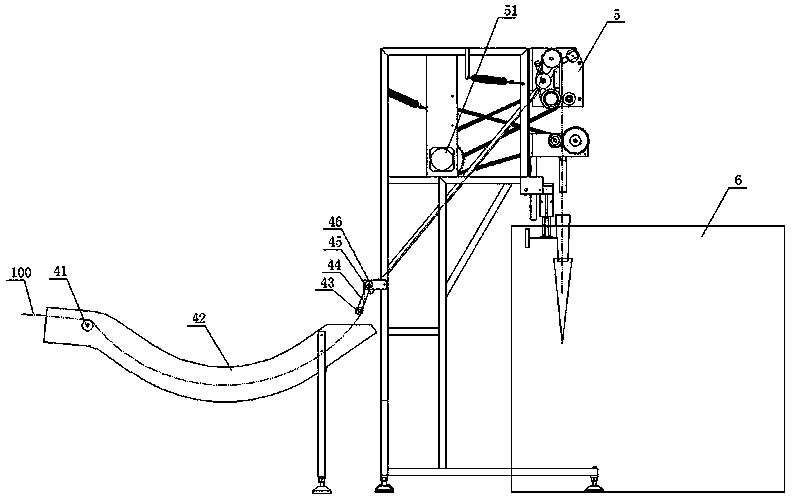

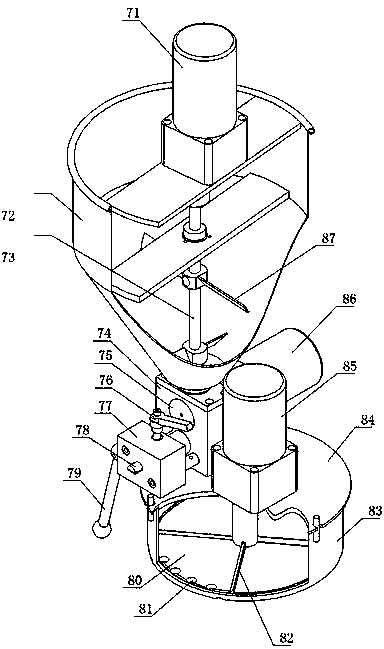

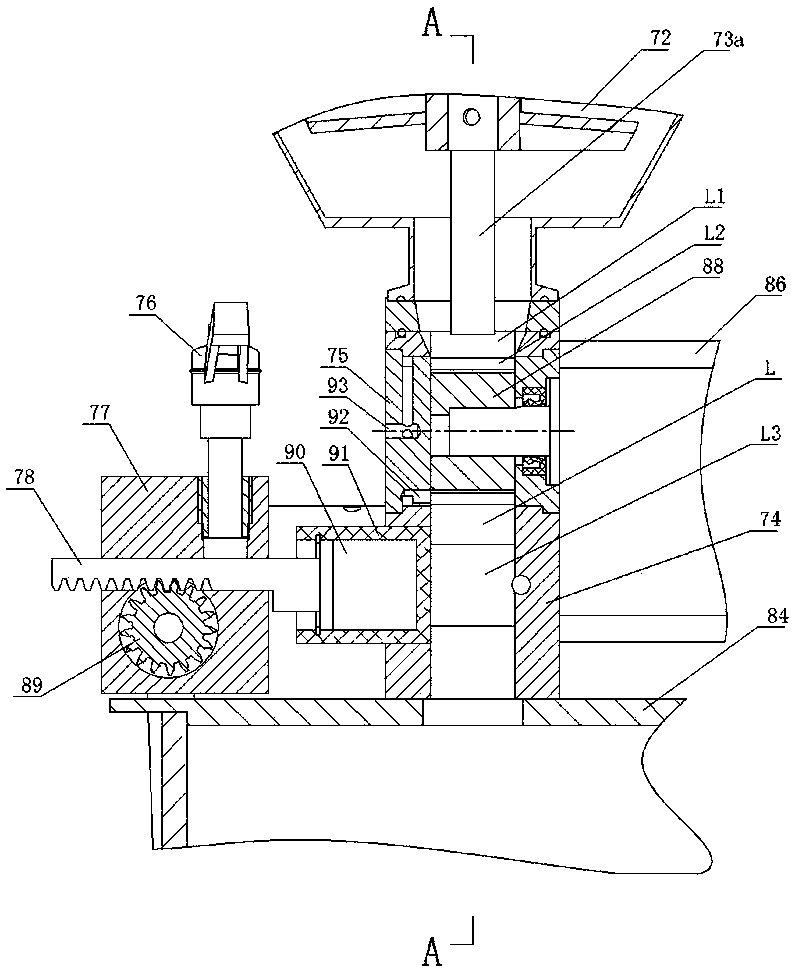

[0022] As shown in the figure, the automatic production line for spicy strips of the present invention includes a flour puffing mechanism 1, a cooling mechanism 2 for upper and lower multi-layer conveyor belts, a vibrating feeding mechanism 3, a condiment feeding mechanism 7, a material passing mechanism 4, and a spicy strip feeding and cutting mechanism 5 And hot strip packaging mechanism 6, spicy strip packaging mechanism 6 can directly replace with bag-type packing machine; Described vibrating feeding mechanism comprises elongated feeding chute 31, feeding frame 33 and vibrating device 32, and feeding trough 31 is with certain The horizontal bevel is installed on the feed frame 33, the feed end height of the feed chute 31 is higher than the discharge end height, the feed trough 31 is driven by the vibration device 32 to vibrate up and down, and the horizontal bevel angle of the feed chute 31 is controlled at 5-8o. Described condiment feeding mechanism 7 is provided with abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com