Method for producing instant leisure peeled prawn food

The technology of a snack food and a processing method is applied in the field of food processing to achieve the effects of improving edibility, fine texture of shrimp meat and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0023] [Implementation case 1] Determination of the eutectic point of shrimp

[0024] The state in which the solute and water are both frozen is a eutectic, and the freezing temperature is the eutectic point, which can be determined by the resistance method. In the process of gradually heating up the shrimp from the frozen state, the resistance in the shrimp will gradually decrease, and when the eutectic point is reached, the resistance will change suddenly. Freeze 200g of shrimp in a -80°C refrigerator for 2 to 3 hours, take out the frozen shrimp, make it warm up gradually, and observe the change of its resistance value. Through the above experiments, it is found that when the temperature of the shrimp increases to -20~-25°C, the resistance value of the shrimp changes suddenly, so it is determined that the eutectic point of the shrimp is at -20~-25°C.

Embodiment example 2

[0025] [Implementation Case 2] Preparation of Spicy Instant Shrimp Snack Food

[0026] Shell the fresh macrobrachium, take out the whole shrimp, wash 3 times to ensure that the shrimp is clean, put the cleaned shrimp on the sieve to drain, after the water is drained, put it in 95-100 ℃ hot water to mature for 2-5 minutes , take it out, drain the water to the fullest, weigh 1KG and put it into the spicy-flavored seasoning for mixing.

[0027] The formula of spicy flavor seasoning is: salt 1.2%, monosodium glutamate 0.4%, chicken essence 0.4%, I+G 0.008%, chili oil 4%, pepper oil 0.24%, acetic acid 0.02%, potassium sorbate 0.03%. The weight of shrimp is 1 (100%).

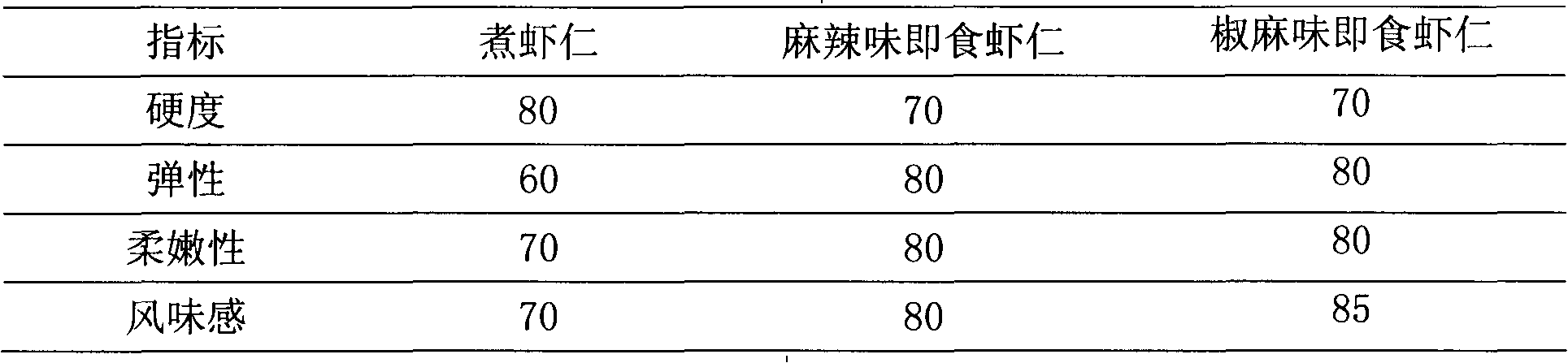

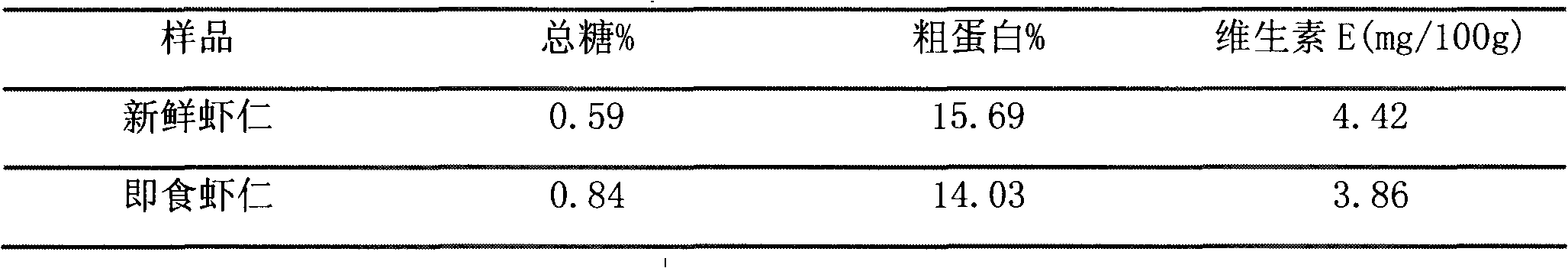

[0028] The mixed shrimps were put into the vacuum freeze-drying equipment, and the shrimps were freeze-dried through three stages of pre-freezing, sublimation drying and analytical drying, and a total of 238.6g of spicy instant shrimp snack food was obtained.

Embodiment example 3

[0029] 【Implementation Case 3】Preparation of Pepper and Mawei Instant Shrimp Snack Food

[0030] Shell the fresh macrobrachium, take out the whole shrimp, wash 3 times to ensure that the shrimp is clean, put the cleaned shrimp on the sieve to drain, after the water is drained, put it in 95-100 ℃ hot water to mature for 2-5 minutes , take it out, drain the water to the fullest, weigh 1KG and put it into the spicy-flavored seasoning for mixing.

[0031]The preparation method of the peppery-flavored seasoning is: scallion 10, pepper 2, soy sauce 12, vinegar 2, and a little monosodium glutamate. Soak Zanthoxylum bungeanum in wine overnight, then crush it with scallion whites until it becomes a puree, and add soy sauce, sugar, vinegar, etc. to make it.

[0032] Put the mixed shrimps into the vacuum freeze-drying equipment, and freeze-dry the shrimps through three stages of pre-freezing, sublimation drying, and analytical drying, and obtain a total of 244.3 g of peppery and spicy i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com