Extraction method of isolated vegetable protein

A protein separation and extraction method technology, applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of heavy beany smell, healthy diet restrictions, and high Na value of the final product, achieving environmental friendliness and improving safety Sex, the effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

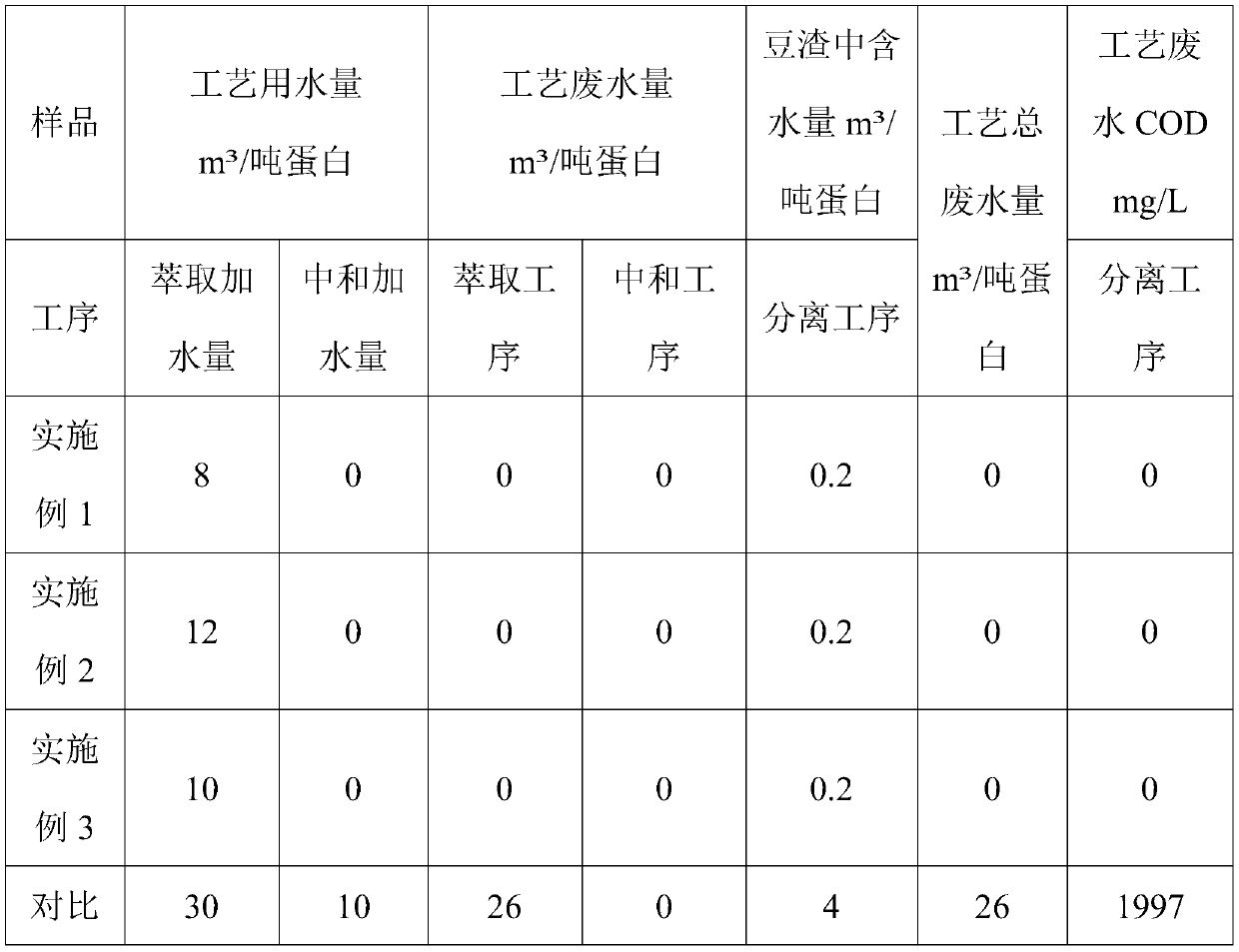

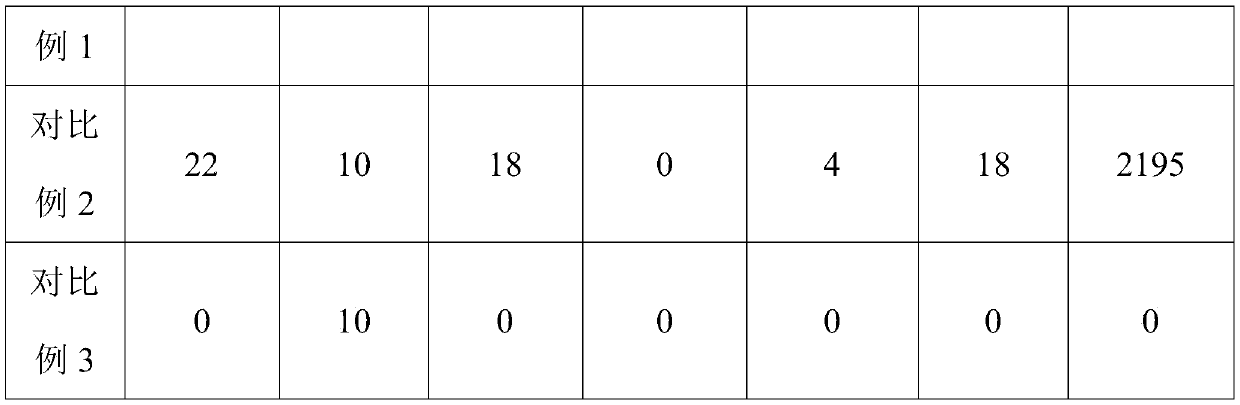

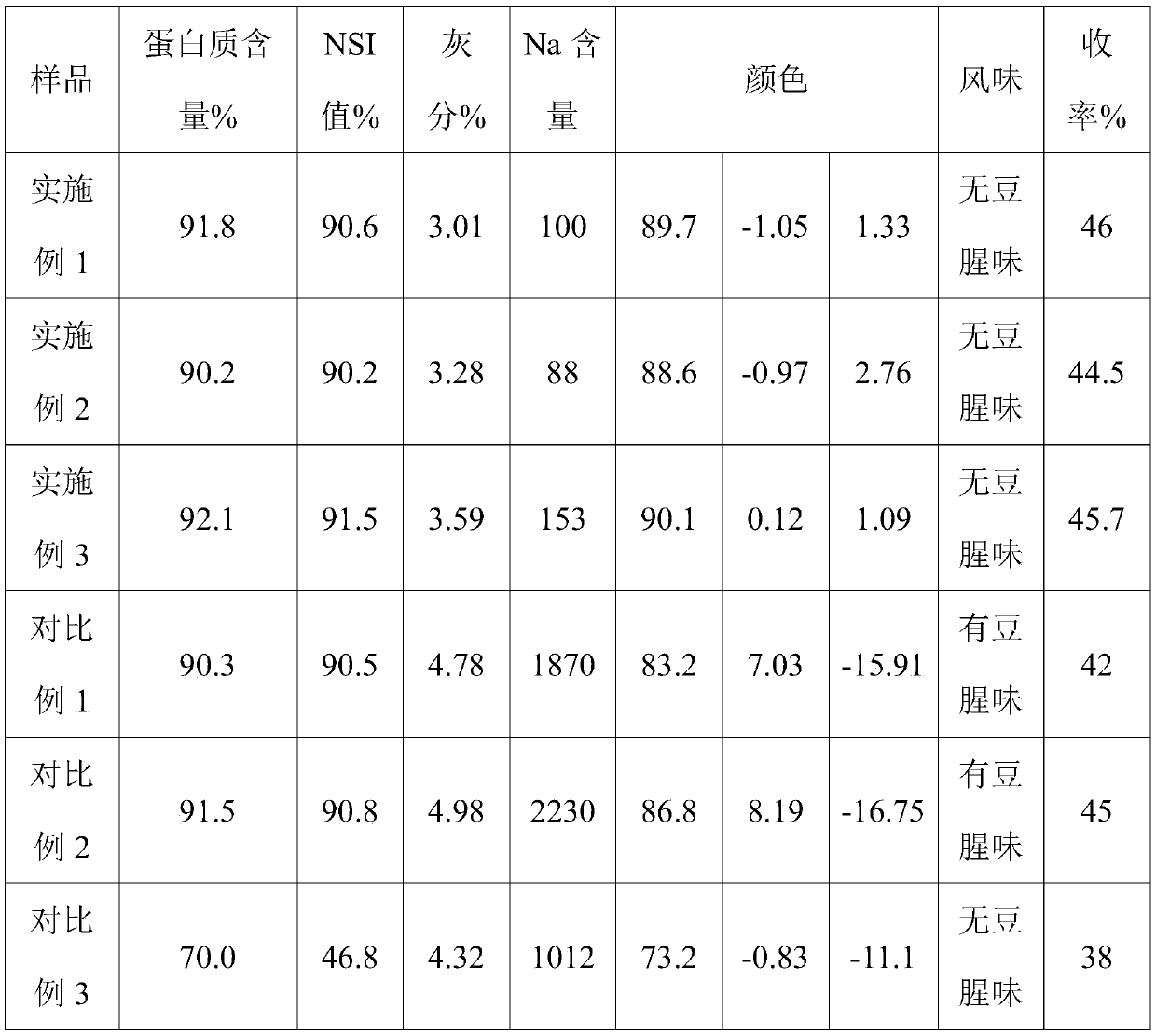

Examples

Embodiment 1

[0024] A method for extracting soybean protein isolate, comprising the following steps:

[0025] (1) Soak the soybean meal after low-temperature degreasing with 3% ethanol, the dosage ratio of soybean meal and ethanol solution is 1:6, stir during the soaking process, the stirring speed is 10Hz, the soaking time is 60min, and the soaking temperature is 55 ℃;

[0026] (2) The mixed solution in the above step (1) is subjected to solid-liquid separation through a centrifuge to obtain a solid, and the liquid after centrifugation is recovered from ethanol and dried to obtain soluble oligosaccharides, and water is added to the solid by high-speed shearing The extraction method is carried out at a speed of 30 Hz, the ratio of the amount of solids to water extracted is 1:4, the water temperature is 50 °C, the extraction time is 60 min, and the pH value of the liquid during the extraction process is 7.0;

[0027] (3) Centrifuge the extract of the above step (2) at a speed of 2000rpm to...

Embodiment 2

[0029] A method for extracting soybean protein isolate, comprising the following steps:

[0030] (1) Take soybean meal after low-temperature degreasing and soak it in ethanol with a volume concentration of 50%. The dosage ratio of soybean meal and ethanol solution is 1:8. Stir during the soaking process. ℃;

[0031] (2) The mixed solution in the above step (1) is subjected to solid-liquid separation through a centrifuge to obtain a solid, and the liquid after centrifugation is recovered from ethanol and dried to obtain soluble oligosaccharides, and water is added to the solid by high-speed shearing The extraction method is carried out at a rotation speed of 40Hz, the ratio of the amount of solids to water extracted is 1:6, the water temperature is 40°C, the extraction time is 40min, and the pH value of the liquid during the extraction process is 7.5;

[0032] (3) Centrifuge the extract of the above step (2) at a speed of 3000rpm to obtain a protein solution, perform flash ste...

Embodiment 3

[0034] A method for extracting soybean protein isolate, comprising the following steps:

[0035] (1) Take soybean meal after low-temperature degreasing and soak it in ethanol with a volume concentration of 75%. The dosage ratio of soybean meal and ethanol solution is 1:10. Stir during soaking. ℃;

[0036] (2) The mixed solution in the above step (1) is subjected to solid-liquid separation through a centrifuge to obtain a solid, and the liquid after centrifugation is recovered from ethanol and dried to obtain soluble oligosaccharides, and water is added to the solid by high-speed shearing The extraction method is carried out at a rotation speed of 50 Hz, the ratio of the amount of extracted solids to water is 1:5, the water temperature is 20 °C, the extraction time is 20 min, and the pH value of the liquid during the extraction process is 7.0;

[0037] (3) The extract of the above step (2) is centrifuged at a speed of 4000rpm to obtain a protein solution, which is flash-steril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com