Method for separating mogroside V

A technology of Mogroside and Luo Han Guo, which is applied in the direction of chemical instruments and methods, glycoside steroids, steroids, etc., can solve the problems of unfavorable decolorization and purification treatment, low content of active ingredients, and deepening of the color of the extract, achieving less solvent residue, The effect of stable product quality and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

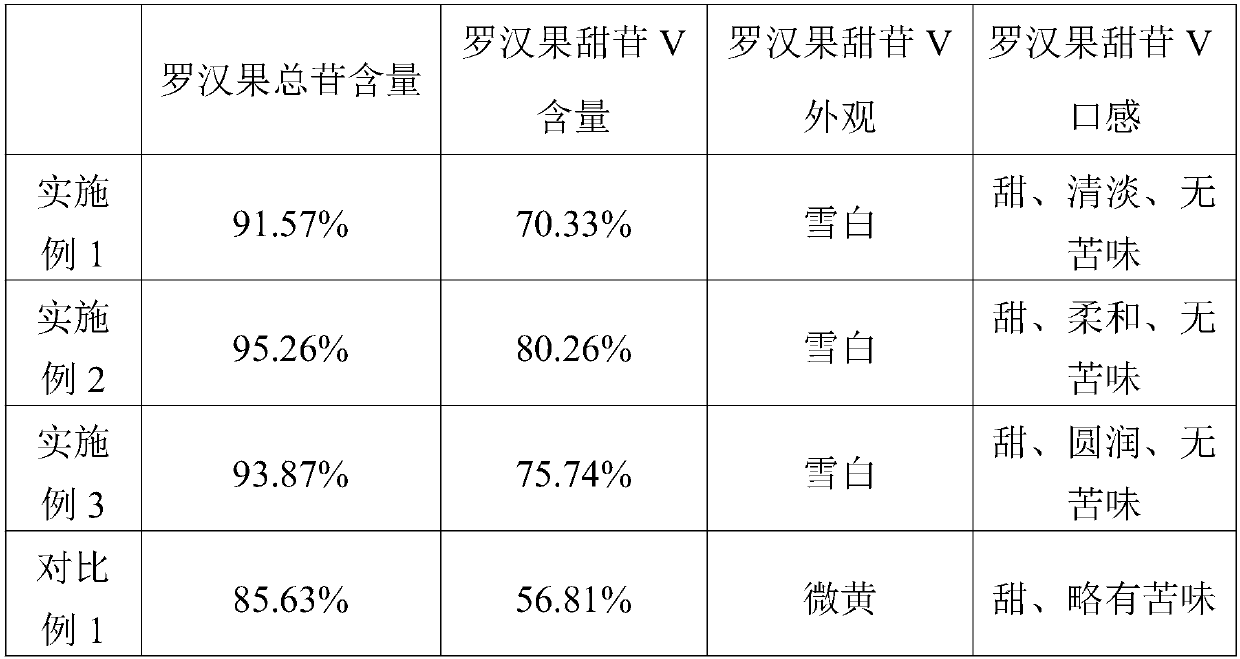

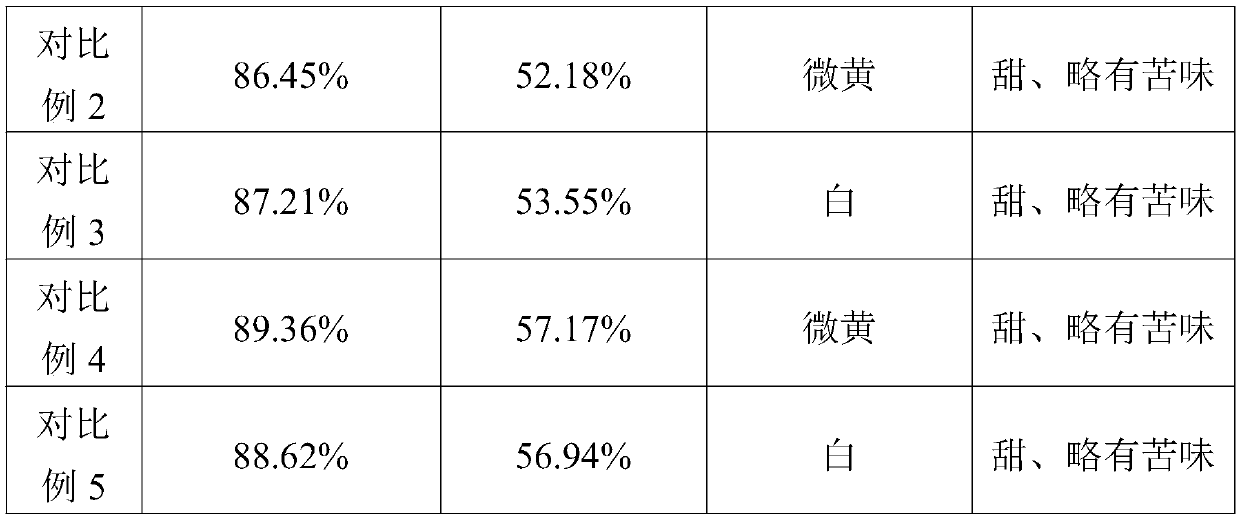

Examples

Embodiment 1

[0027] Take 1kg of ripe and fresh Luo Han Guo, crush it, add 3kg of pure water and beat it with a beater. Adjust the pH to 4.0 with 3% citric acid, add 0.5 ml of cellulase, and perform enzymatic hydrolysis at 40°C for 1 hour. Through a 100-mesh filter cloth, 3 ml of pectin lyase, 3 ml of papain, 3 ml of acid protease, 3 ml of amylase, and 3 ml of beta-galactanase were added, and the enzymolysis was carried out at 45 ° C for 1 hour to obtain Enzymolysis solution, heat the enzymolysis solution to 80°C, keep it for 5 minutes to inactivate the enzyme, let it cool to 25°C, add 0.5g of high-activity yeast powder (purchased from Angel Yeast (Chongzuo) Co., Ltd.), under aerobic conditions Ferment for 3 hours. Pass the fermentation liquid through an organic membrane, first pass through an organic membrane with a molecular weight of 5000, and the membrane inlet pressure is 0.45MPa, and then pass through an organic membrane with a molecular weight of 400, and the membrane inlet pressure...

Embodiment 2

[0029] Take 1kg of ripe and fresh Luo Han Guo, crush it, add 4kg of pure water and beat it with a beater. Adjust the pH to 4.5 with 4% citric acid, first add 0.5 ml of hemicellulase, 0.5 ml of β-glucanase, and 0.5 ml of pectinase, and perform enzymatic hydrolysis at 42° C. for 3 hours. Continue to add 0.5ml of pectin lyase through a 200-mesh filter cloth, enzymolyze at 48°C for 2 hours to obtain an enzymatic hydrolysis solution, heat the enzymatic hydrolysis solution to 83°C, keep it for 8 minutes to inactivate the enzyme, and let it cool to 27°C , add 1 g of high active yeast powder (purchased from Angel Yeast (Chongzuo) Co., Ltd.), and ferment for 4 hours under aerobic conditions. Pass the fermentation liquid through an organic membrane, first pass through an organic membrane with a molecular weight of 5000, the membrane inlet pressure is 0.48MPa, and then pass through an organic membrane with a molecular weight of 400, and the membrane inlet pressure is 1.9MPa to obtain a d...

Embodiment 3

[0031] Take 1kg of ripe and fresh Luo Han Guo, crush it, add 5kg of pure water and beat it with a beater. Use 5% citric acid to adjust the pH to 4.8, first add 0.6ml of cellulase, 0.6ml of hemicellulase, 0.6ml of β-glucanase, 0.6ml of pectinase, and 0.6ml of cellulase, a total of five enzymes , add a total of 3ml, and enzymatically hydrolyze at 45°C for 5 hours. Through a 200-mesh filter cloth, continue to add papain 1ml, acid protease 1ml, amylase 1ml, a total of three enzymes, and enzymolyze at 50°C for 3 hours to obtain an enzymatic hydrolysis solution. Heat the enzymatic hydrolysis solution to 85°C and keep it for 10 minutes Inactivate the enzyme, let it cool to 30°C, add 5g of high-activity yeast powder (purchased from Angel Yeast (Chongzuo) Co., Ltd.), and ferment for 5 hours under aerobic conditions. Pass the fermentation liquid through an organic membrane, first pass through an organic membrane with a molecular weight of 5000, and the membrane inlet pressure is 0.5MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com