Composite board containing moxa residue as well as preparation method and application thereof

A composite plate and composite additive technology, applied in the field of materials, can solve the problems of easy deformation, high price, poor bending strength, etc., and achieve the effects of not easy to crack, good bending strength, and improved anti-mildew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

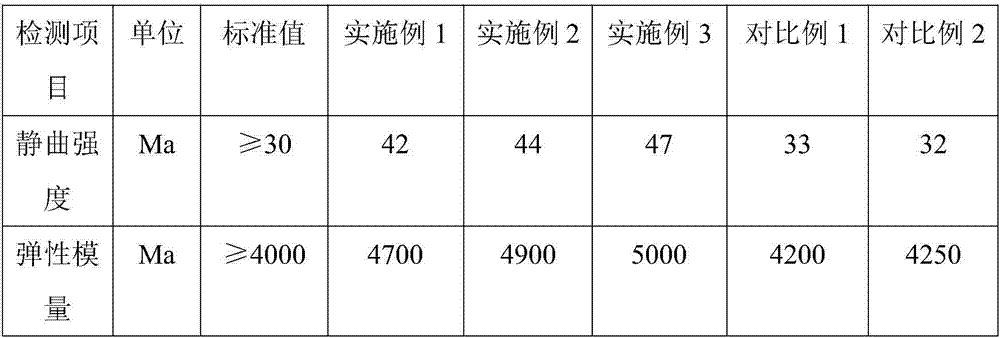

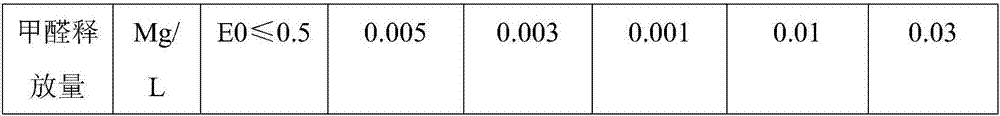

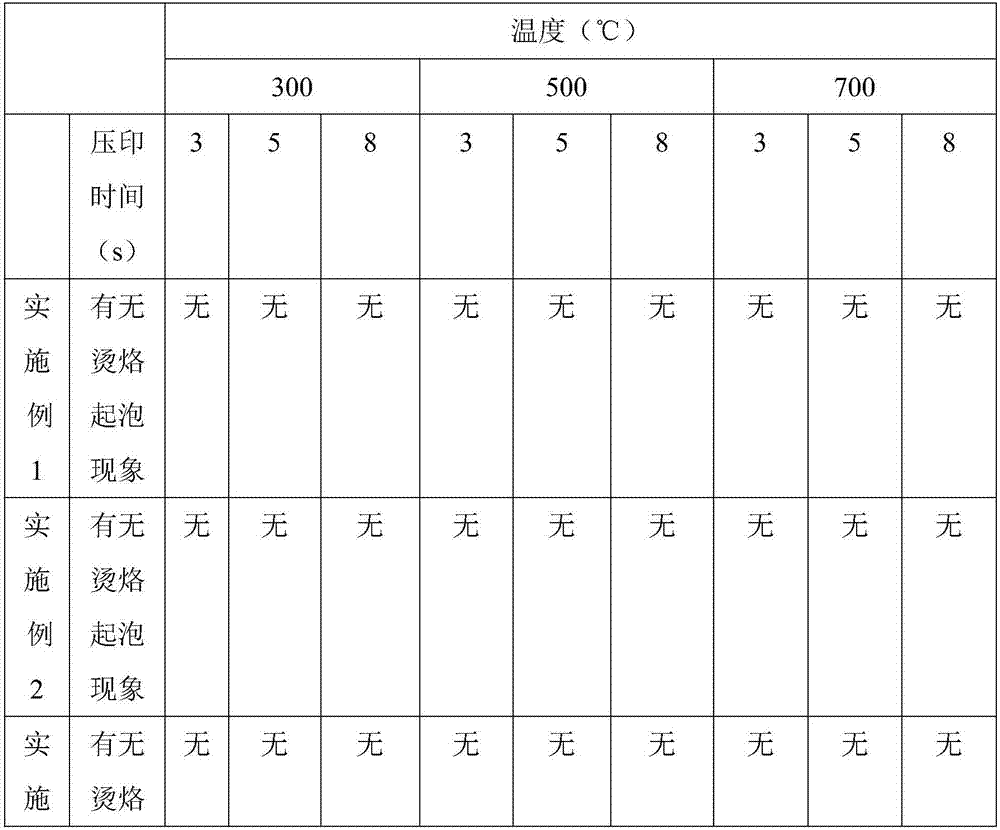

Examples

Embodiment 1

[0042] Embodiment 1, a kind of composite sheet material containing moxa slag

[0043]The composite board containing moxa slag comprises a face plate, a core board, a back board and an adhesive layer, and the face plate, the core board and the back board are glued together by the adhesive layer, and the face board and the back board are poplar boards; the core board is composed of the following The raw material of weight ratio is made: mugwort slag 11, wood powder 63, bamboo charcoal powder 3, bamboo powder 15 and soybean meal adhesive 6; Described adhesive layer comprises compound additive and adhesive, the compound additive and adhesive The weight ratio is 1:16.

[0044] The composite additive is composed of hydroxyapatite, jade powder and attapulgite in a weight ratio of 1:7:11.

[0045] The adhesive is soybean meal adhesive.

[0046] The preparation method of described mugwort slag comprises the following steps:

[0047] Crush Artemisia argyi leaves, pass through an 80-m...

Embodiment 2

[0057] Embodiment 2, a kind of composite plate containing moxa slag

[0058] The composite plate containing moxa slag comprises a face plate, a core plate, a back plate and an adhesive layer, and the face plate, the core plate and the back plate are glued together by the adhesive layer, and the face plate and the back plate are birch boards; the core plate is composed of the following The raw material of weight ratio is made: moxa residue 15, wood powder 68, bamboo charcoal powder 6, bamboo powder 20 and soybean meal adhesive 12; Described adhesive layer comprises compound additive and adhesive, the compound additive and adhesive The weight ratio is 3:14.

[0059] The composite additive is composed of hydroxyapatite, jade powder and attapulgite in a weight ratio of 3:5:9.

[0060] The adhesive is soybean meal adhesive.

[0061] The preparation method of described mugwort slag comprises the following steps:

[0062] Crush Artemisia argyi leaves, pass through an 80-mesh sieve...

Embodiment 3

[0072] Embodiment 3, a kind of composite plate containing moxa slag

[0073] The composite plate containing moxa slag comprises a face plate, a core plate, a back plate and an adhesive layer, and the face plate, the core plate and the back plate are glued together by the adhesive layer, and the face plate and the back plate are basswood boards; the core plate is composed of the following The raw material of weight ratio is made: mugwort slag 13, wood powder 66, bamboo charcoal powder 5, bamboo powder 18 and soybean meal adhesive 11; Described adhesive layer comprises compound additive and adhesive, the compound additive and adhesive The weight ratio is 2:15.

[0074] The composite additive is composed of hydroxyapatite, jade powder and attapulgite in a weight ratio of 2:5:10.

[0075] The adhesive is soybean meal adhesive.

[0076] The preparation method of described mugwort slag comprises the following steps:

[0077] Crush Artemisia argyi leaves, pass through an 80-mesh s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com