Modified flame-retardant urea-formaldehyde resin adhesive for producing artificial boards and preparation method of same

A technology for urea-formaldehyde resin glue and wood-based panels, which is applied in adhesives, starch-derived adhesives, polyurea/polyurethane adhesives, etc., and can solve the problems of increased difficulty in product quality control, decreased resin reactivity, and decreased storage stability, etc. problems, to avoid drying evaporation loss, reduce free formaldehyde, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

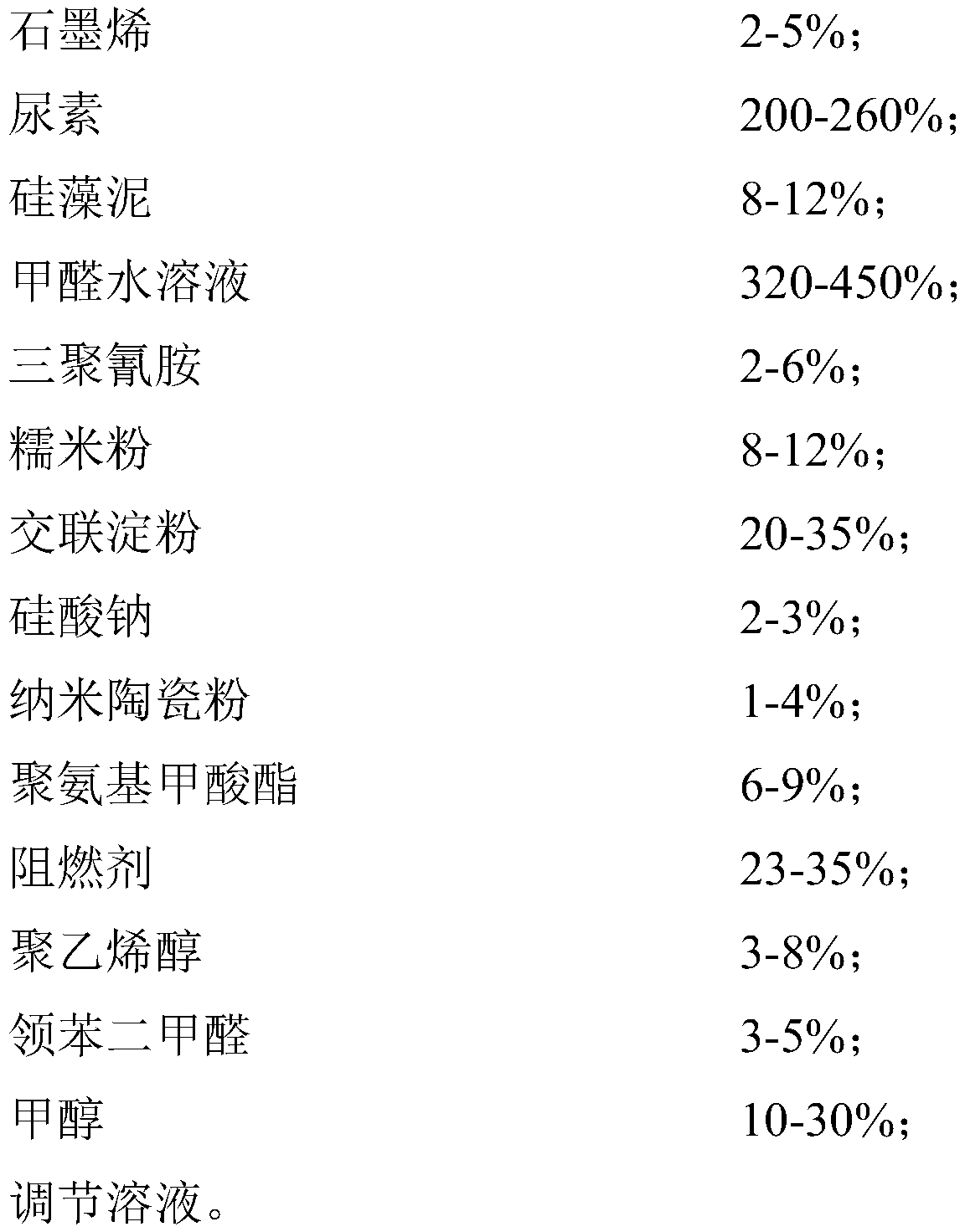

[0032] The present invention also provides a method for preparing a modified flame-retardant urea-formaldehyde resin glue for producing wood-based panels, comprising the following steps:

[0033] 1) Put 320-450% by weight of formaldehyde solution into the enamel reaction kettle, adjust the pH value to alkaline with the adjusting solution, then add 3-8% by weight of polyvinyl alcohol, 100- 140% by weight of urea, which is heated up to 90-95°C and reacted for 40-50min;

[0034] 2) After the reaction, add 10-30% by weight of methanol and 1-2% by weight of melamine after the enamel reactor cools down, and adjust the pH value of the solution in the enamel reactor to 7.5- 8.8, heat up to 75-80°C, then put 100-120% by weight of urea into the enamel reactor for reaction;

[0035] 3) After the reaction in step 2), add 1-4% by weight of melamine and 3-5% by weight of phthalaldehyde, stir for 15-30min, and distill under reduced pressure to recycle the obtained formaldehyde;

[0036] 4)...

Embodiment 1

[0043] 1) Put 320% by weight of formaldehyde solution into the enamel reaction kettle, adjust the pH value to be alkaline with the adjusting solution, then add 3% by weight of polyvinyl alcohol and 100% by weight of urea to the enamel reaction kettle , raise its temperature to 90°C, and react for 400min;

[0044] 2) After the reaction, add 10% by weight of methyl alcohol and 1% by weight of melamine after the enamel reactor cools down, and adjust the pH value of the solution in the enamel reactor to 7.5-8.8 with the adjustment solution after the polycondensation is completed, and heat up to 75°C, and then put 100% urea by weight into the enamel reactor to react;

[0045] 3) After the reaction in step 2), add 1% by weight of melamine and 3% by weight of phthalaldehyde, stir for 15 minutes, and distill under reduced pressure to recycle the obtained formaldehyde;

[0046] 4) After continuing to heat up to 85°C, keep warm for ten minutes and add 23% by weight of flame retardant, 8%...

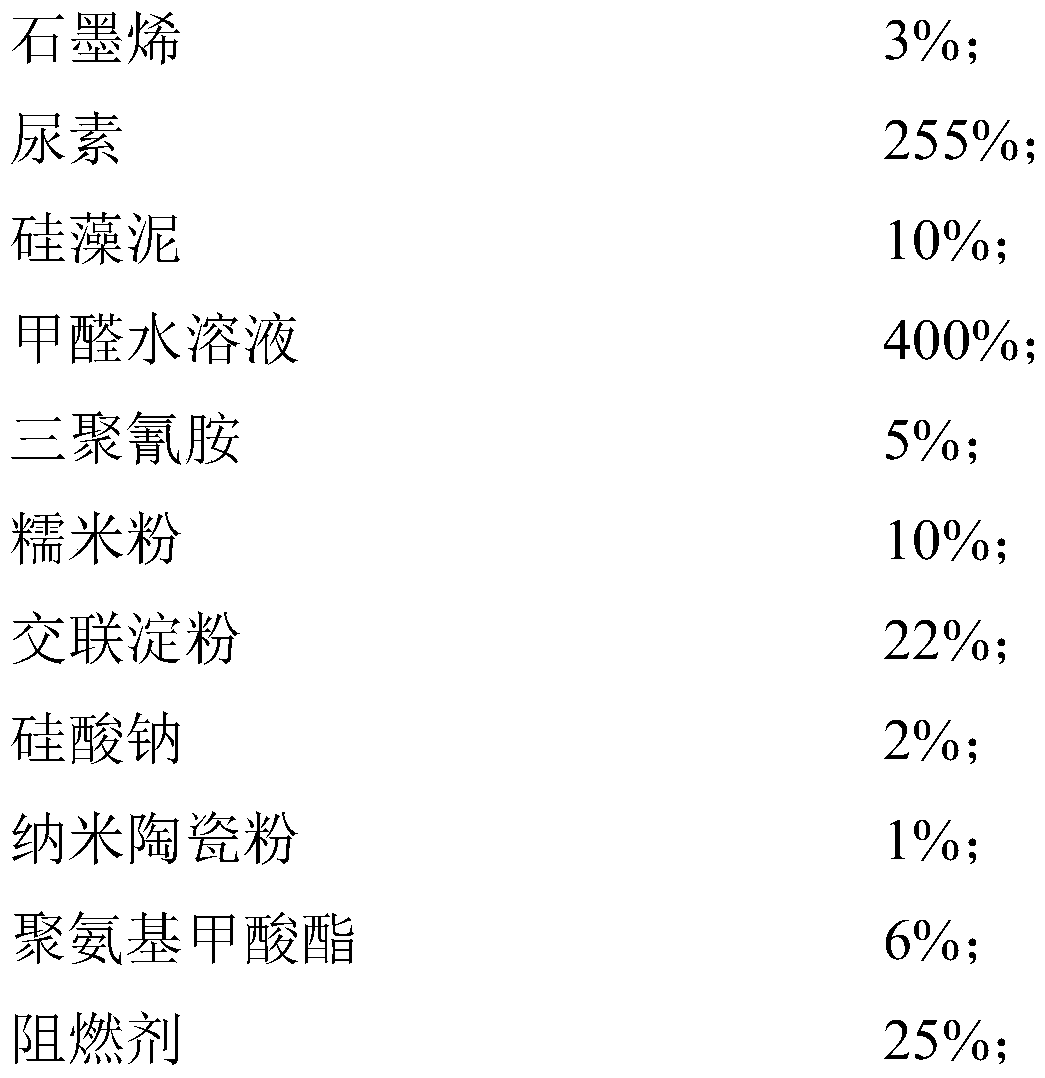

Embodiment 2

[0052] 1) Put 450% by weight of formaldehyde solution into the enamel reaction kettle, adjust the pH value to be alkaline with the adjusting solution, then add 8% by weight of polyvinyl alcohol and 140% by weight of urea to the enamel reaction kettle , raise its temperature to 95°C, and react for 50min;

[0053] 2) After the reaction, add 30% by weight of methanol and 2% by weight of melamine after the enamel reactor cools down, adjust the pH value of the solution in the enamel reactor to 8.8 with the adjusting solution after the polycondensation is completed, and heat up to 80°C , then drop into 120% urea by weight in the enamel reactor to react;

[0054] 3) After the reaction in step 2), add 4% by weight of melamine and 5% by weight of phthalaldehyde, stir for 15-30min, distill under reduced pressure, and recycle the obtained formaldehyde;

[0055] 4) After continuing to heat up to 90°C, keep warm for ten minutes and add 35% by weight of flame retardant, 12% by weight of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com