Preparation method of high-purity aluminum oxide for sapphire

A high-purity alumina and sapphire technology, applied in the preparation of alumina/hydroxide, purification of aluminate/alumina/aluminum hydroxide, etc., can solve problems such as inability to use optoelectronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

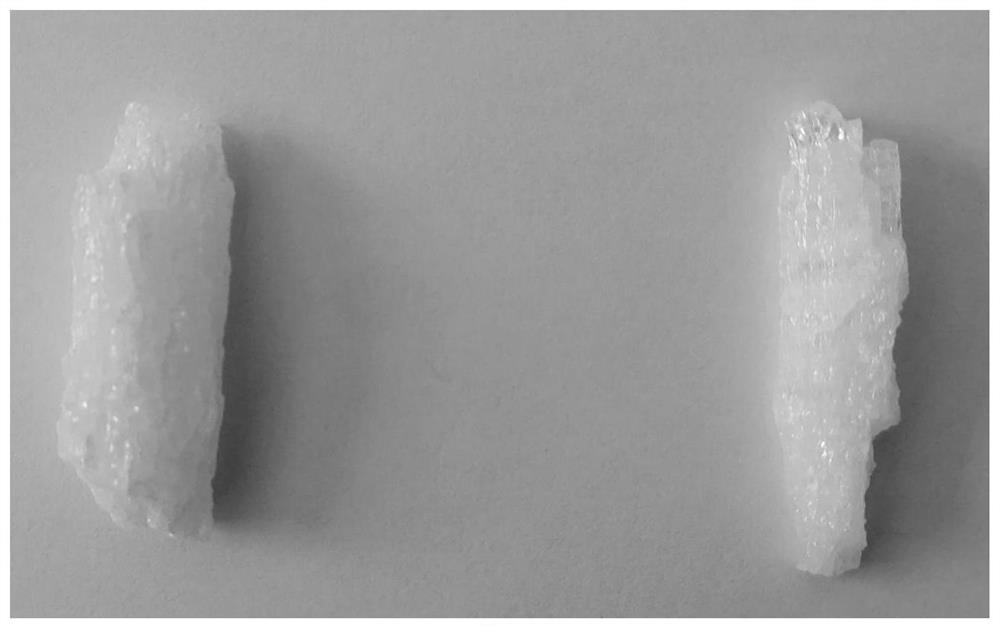

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing high-purity alumina for sapphire, comprising the following steps:

[0023] Under stirring conditions, aluminum alkoxide and water are mixed to carry out hydrolysis reaction to obtain pseudo-boehmite-alcohol-water slurry;

[0024] remove the alcohol in the pseudo-boehmite-alcohol-water slurry, then mix the resulting material with a carbon remover and water to obtain a mixed material; the carbon remover is aqueous hydrogen peroxide, chlorine dioxide, chlorine ammonium perchlorate, persulfuric acid, ammonium persulfate, nitric acid, ammonium nitrate, aluminum nitrate nonahydrate, concentrated sulfuric acid, ammonium sulfate, aluminum sulfate octadecahydrate, concentrated hydrochloric acid, ammonium chloride, aluminum chloride hexahydrate, One or more of ammonium fluoride, aluminum fluoride, ammonium iodate and ammonium bromide;

[0025] The mixed material is dried and calcined in sequence to obtain high-purity alumina for sapp...

Embodiment 1

[0046] 2kg of liquid aluminum isopropoxide (purity not less than 99%, the total content of metal element impurities such as Na, Fe, Si, K, Ca, Cu, Ti and Zn is less than 0.005wt.%) is introduced into 4L with reflux equipment In the reaction kettle, under the condition of stirring at 80°C (120r / min), add 550g of high-purity water into the reaction kettle, and continue stirring for 4 hours after adding water to hydrolyze aluminum isopropoxide into pseudoboehmite-isopropanol -Water slurry; the slurry is vacuum-dried, the drying temperature is 90°C, and the drying time is 6h; the pseudo-boehmite (AlOOH content is 88.2wt.%) and 10g of aluminum chloride hexahydrate obtained by drying are successively added to the In 700g of high-purity water, mix the above three evenly; the resulting mixture is dried in a blast drying oven at 105°C for 8 hours; the resulting dried product is crushed into a powder with a particle size of less than 150 microns, and then the powder is placed in a ventil...

Embodiment 2

[0050] 2000kg of liquid aluminum isopropoxide (purity not less than 99%, total content of Na, Fe, Si, K, Ca, Cu, Ti, Zn less than 0.005wt.%) is introduced into a 4000L reactor and stirred at 80°C Under the condition (rotating speed is 40r / min), 550kg high-purity water is added in the reactor, after adding water, continue to stir for 4h to hydrolyze aluminum isopropoxide into pseudo-boehmite-isopropanol-water slurry; Process in a circulating flash dryer, the protective gas is nitrogen, the inlet temperature is 250°C, and the discharge temperature is 80°C; the dried pseudo-boehmite (AlOOH content is 84wt.%) and 10kg aluminum chloride hexahydrate are successively Add it into 2000kg of high-purity water, and use a mixer to mix the above three evenly; the resulting mixture is spray-dried with an inlet temperature of 350°C and an outlet temperature of 100°C; the spray-dried powder is placed in a ventilated corundum crucible with a cover, The filling rate is 70%, the filling height i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com