Production technology for novel high-porosity lithium ion battery membrane

A technology for lithium-ion batteries and production processes, which is applied in the field of battery diaphragms, and can solve the problems of reduced porosity of diaphragms and reduced performance of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

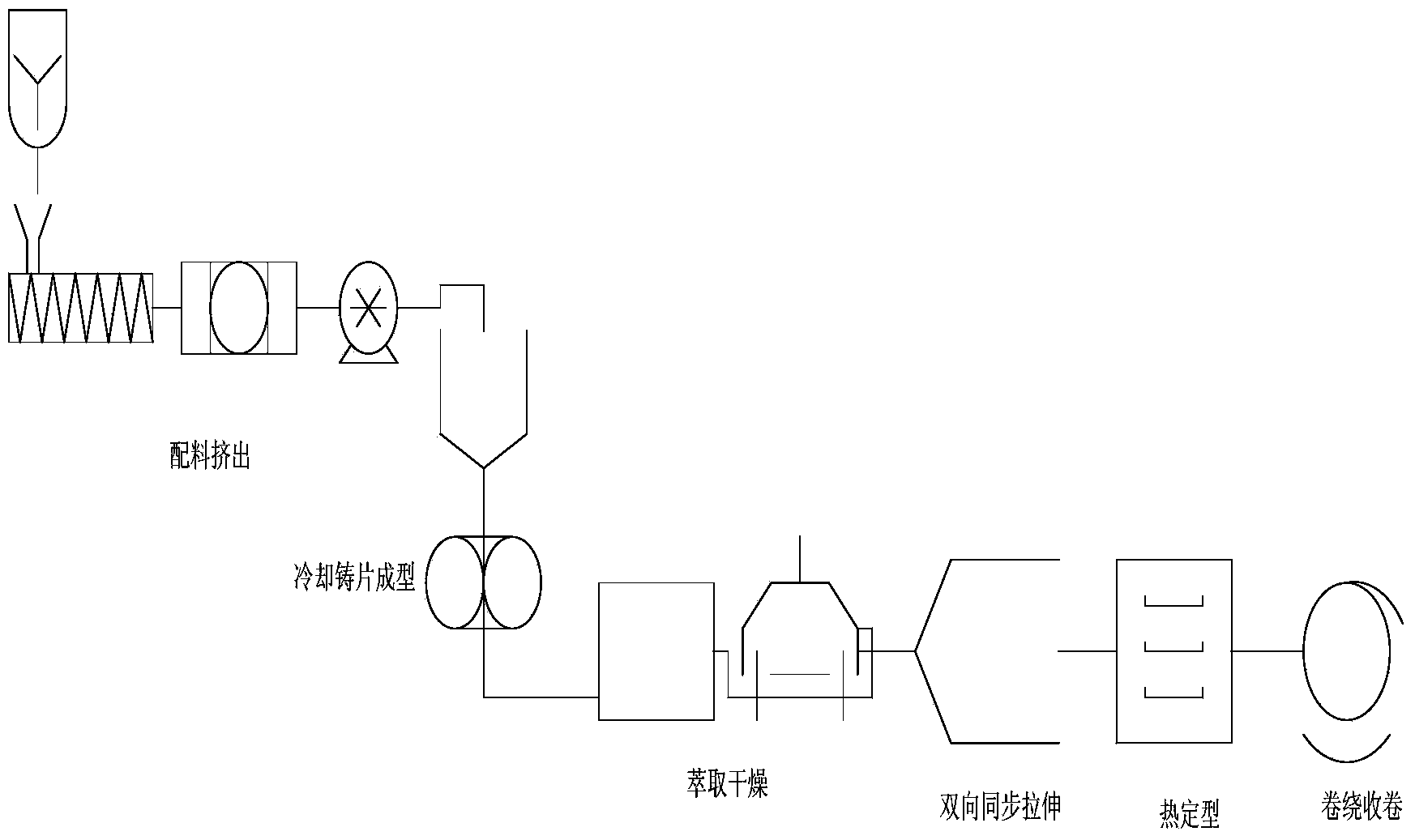

[0029] A kind of preparation method of high-porosity polyethylene lithium battery diaphragm, its operation process flow chart is as follows figure 1 As shown, it mainly includes ingredients—extrusion—filter metering—die extrusion—extraction—drying—biaxial synchronous stretching—heat setting—on-line winding. UHMWPE is used as raw material resin, white oil is used as solvent, and dichloromethane is used as extraction agent.

[0030] The present invention, a kind of preparation method of high-porosity polyethylene lithium battery diaphragm, comprises the following steps:

[0031] Step 1. Ingredients mixing: Weigh polyethylene powder and white oil and mix them uniformly to obtain mixture A, the weight ratio of polyethylene powder and white oil is 1:2-5.5;

[0032] Step 2, extruding, filtering and metering: pass the mixture A in step 1 through a twin-screw extruder with a diameter of 96mm, an aspect ratio of 52, and a temperature of 200°C to obtain a high-temperature melt;

[003...

Embodiment 1

[0041] Step a: To prepare mixture A, first weigh 50Kg of UHMWPE powder (polyvinyl chloride), according to the weight of UHMWPE powder accounting for 16% of the total weight of the final white oil and UHMWPE powder mixture A, and white oil accounting for 85% of the total weight of mixture A. Take 262.5Kg of white oil, pour the white oil and UHMWPE powder into the stirring tank together, preferably the stirrer is in the form of double ribbons for full stirring, and obtain the mixture A for later use;

[0042] Step b: Mixture A is passed through a twin-screw extruder with a diameter of 96mm, an aspect ratio of 52, and a temperature of 200°C to obtain a uniform high-temperature melt of mixture A; the high-temperature melt is filtered through a 500-mesh filter respectively, and the melt pump is metered Enter the extrusion die and extrude;

[0043] Step c: the high-temperature melt flowing out from the slit of the die head passes through four chilling rollers with temperatures of 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com