Monodisperse ternary copolymer microspheres and preparation method thereof

A ternary copolymerization microsphere, monodisperse technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor controllability of particle size, difficulty in meeting production needs, unsatisfactory temperature resistance, etc. Achieve the effects of narrow particle size range, fast polymerization rate and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] According to the method for preparing the above-mentioned monodisperse terpolymeric microspheres provided by the present invention, it comprises the following steps:

[0051] (1) Add the mixed aqueous solution of acrylamide, functional monomer and crosslinking agent to the mixed oil solution of emulsifier and white oil, and after shearing and stirring, a mixed phase liquid is obtained;

[0052] (2) Under the condition of 68±2°C and stirring, add the aqueous solution of the initiator dropwise into the mixed phase liquid, and react for 3-5 hours to obtain the crude product of monodisperse ternary copolymerization microspheres;

[0053] (3) After centrifuging and washing the crude monodisperse terpolymer microspheres, the monodisperse ternary copolymer microspheres are obtained.

[0054] In the above preparation method, preferably, the speed of shear stirring in step (1) is 10000-22000 r / min.

[0055] In the above preparation method, preferably, the shear stirring in step...

specific Embodiment approach

[0059] According to a specific embodiment of the present invention, preferably, the above-mentioned preparation method comprises the following steps:

[0060] (1) Add the mixed aqueous solution of acrylamide, functional monomer and crosslinking agent to the mixed oil solution of emulsifier and white oil, and carry out intermittent shearing and stirring at a speed of 10000-22000r / min. The stirring time is 6min, after carrying out 3 times of shearing and stirring, a mixed phase liquid is obtained, and the mixed phase liquid is poured into a container equipped with a thermometer, an agitator, and a condensation reflux device;

[0061] (2) In a constant temperature water bath at 68±2°C and under stirring conditions of 600-750r / min, use a constant pressure funnel to drop the aqueous solution of the initiator into the mixed phase liquid at a rate of two drops / s, After reacting for 4h, the crude product of monodisperse ternary copolymerized microspheres was obtained;

[0062] (3) Af...

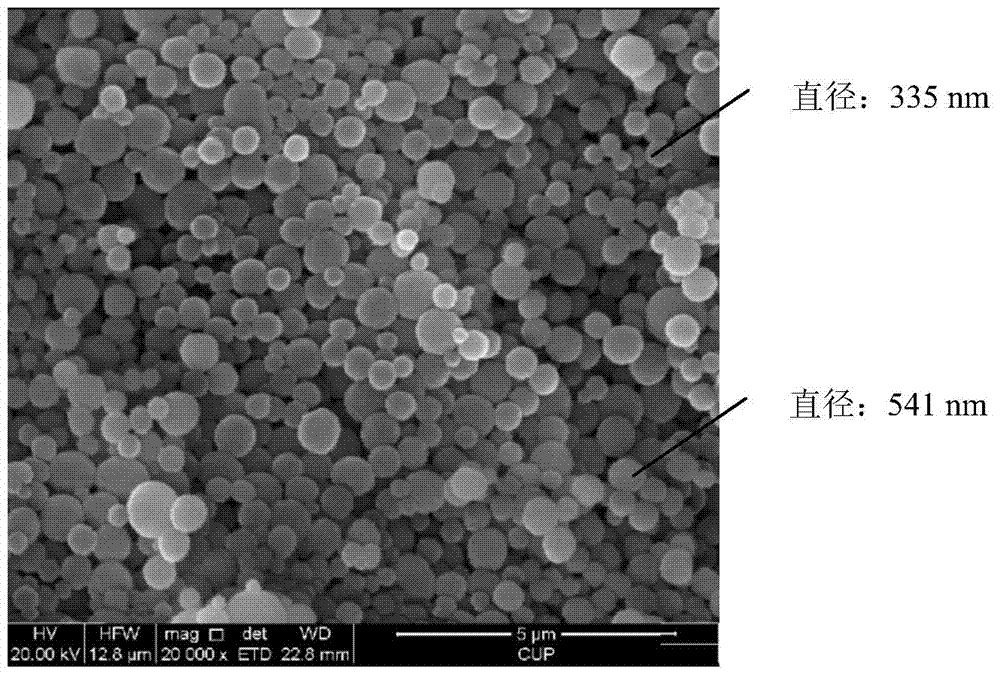

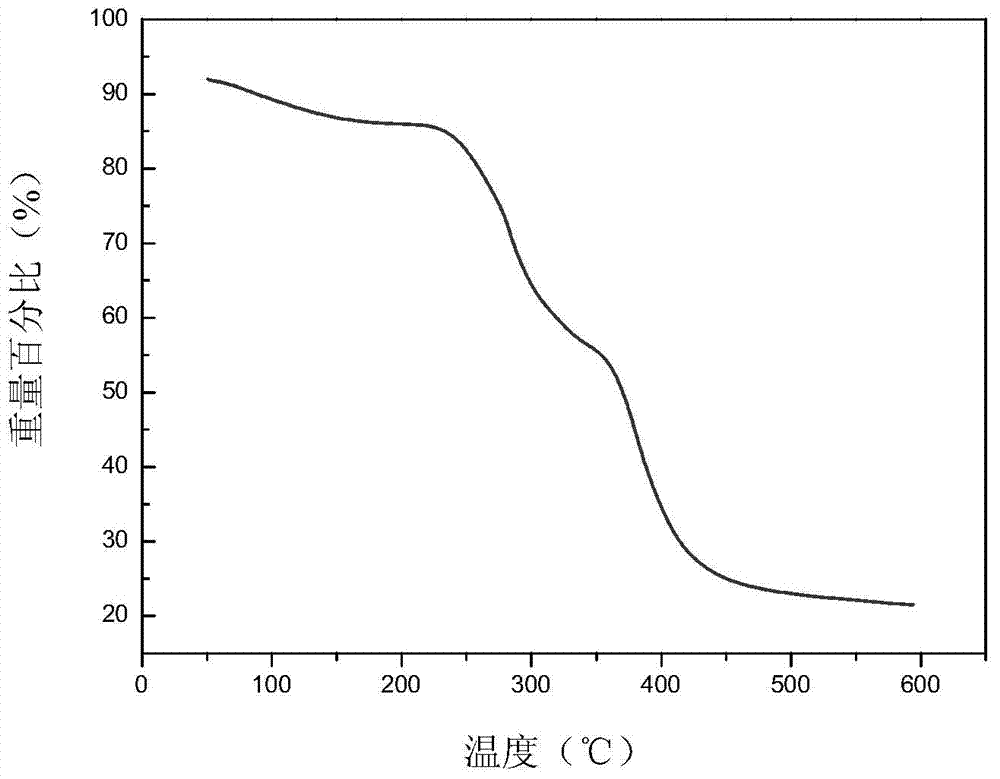

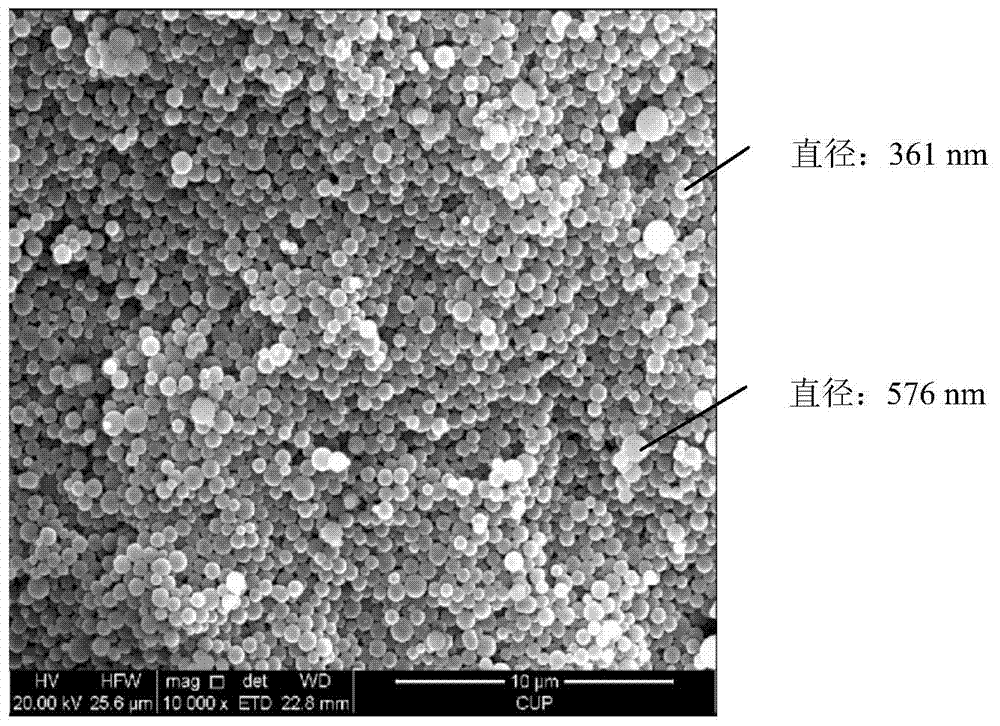

specific Embodiment 1

[0066] This example provides a kind of monodisperse ternary copolymerization microspheres, its raw material composition includes: acrylamide 6%, 2-acrylamide-2-methylpropanesulfonic acid 1.5%, N-vinylpyrrolidone 2.5% by weight percentage %, N,N'-methylenebisacryloyl 0.1%, potassium persulfate 0.1%, white oil 55%, Span 803.6%, Tween 601.2% and water 30%.

[0067] The preparation method of the monodisperse ternary copolymerization microsphere of the present embodiment comprises the following steps:

[0068] (1) Dissolve acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, N-vinylpyrrolidone and N,N'-methylenebisacryloyl in water according to the above weight percentage (the amount of water 25%), magnetically stirred until transparent to obtain a mixed aqueous solution;

[0069] (2) Dissolve Span 80 and Tween 60 in white oil, and magnetically stir until transparent to obtain a mixed oil solution;

[0070] (3) Potassium persulfate was dissolved in water (the amount of water wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com