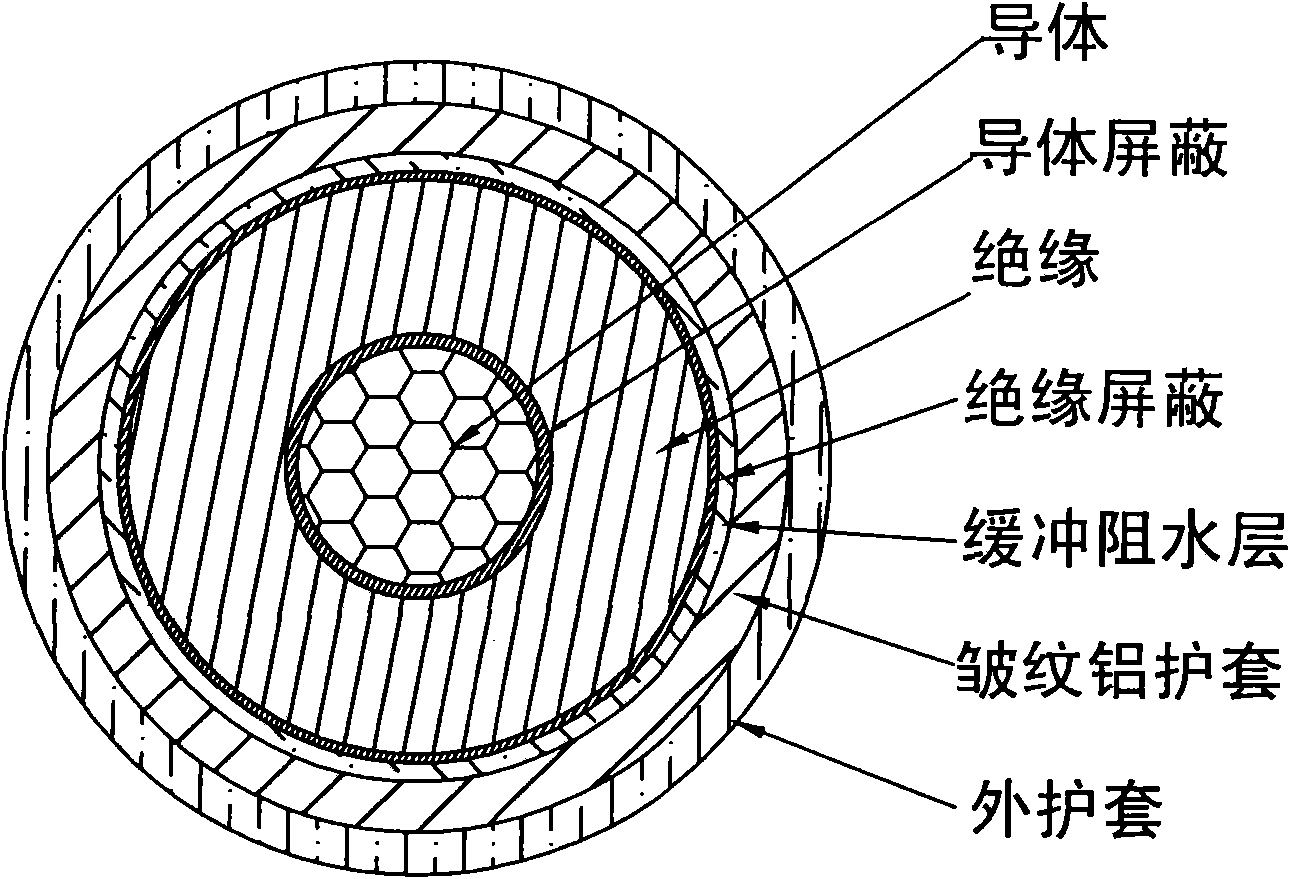

Preparation method of semiconductive shielding material for 110kV and above voltage class cables

A technology of voltage level and shielding material, applied in the direction of power cable with shielding layer/conducting layer, etc., can solve the problems of easy catalytic aging by metal, short service life, product performance far from meeting semi-conductive shielding material, etc., which is not easy to achieve. The effect of blocking, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

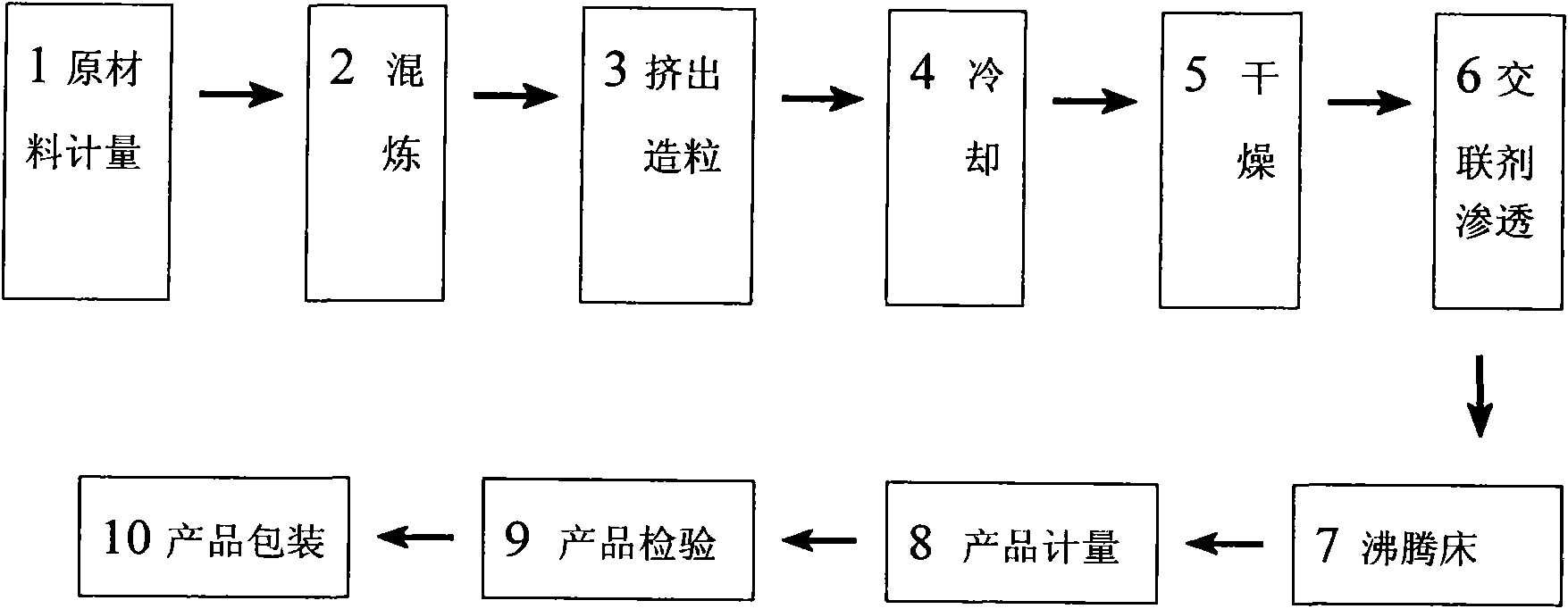

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 (the following components are parts by weight):

[0042] Step 1, get 66 parts of ethylene-acrylic acid ethyl ester resins, 31 parts of 320 mesh conductive carbon blacks (Belgian production), antioxidant 4,4-thiobis(6-tert-butyl-3-methylphenol) and bis 0.5 part of mixture of [(phenylmethylene) hydrazide] oxalic acid, (wherein bis[(phenylmethylene) hydrazide] oxalic acid content is 0.5% by weight), and the number average molecular weight is 5000~ 7500 polyethylene wax 1.5 parts, 7 # 3.5 parts of industrial white oil, 0.9 parts of ethylene glycol, 0.4 parts of titanate coupling agent and 1 part of zinc stearate were added to the tipping bucket mixer, closed and mixed for 8 minutes, and the mature rubber was mixed. Wherein the melt index of the ethylene-ethyl acrylate resin is 6, and the content of acrylic acid is 15% by weight.

[0043] Step 2: Send the kneaded cooked rubber to a reciprocating stepped extruder for secondary kneading and granulation to make a...

Embodiment 2

[0049]The difference between this embodiment and Example 1 is: 65 parts of ethylene-acrylic acid ethyl resin, 32 parts of 300 mesh conductive carbon black, antioxidant 4,4-thiobis(6-tert-butyl-3-methylphenol ) and 1 part of the mixture of bis[(phenylmethylene)hydrazide]oxalic acid, (wherein the content of bis[(phenylmethylene)hydrazide]oxalic acid is 0.4% by weight), and the molecular weight is 5000 ~7500 polyethylene wax 1 part, 7 # 3 parts of industrial white oil, 0.8 parts of ethylene glycol, 0.8 parts of titanate coupling agent, 0.5 parts of zinc stearate, and 0.4 parts of dicumyl peroxide.

Embodiment 3

[0051] The difference between this embodiment and Example 1 is: 68 parts of ethylene-acrylic acid ethyl resin, 30 parts of 320 mesh conductive carbon black, antioxidant 4,4-thiobis(6-tert-butyl-3-methylphenol ) and 0.3 parts of a mixture of bis[(phenylmethylene)hydrazide]oxalic acid, (wherein the content of bis[(phenylmethylene)hydrazide]oxalic acid is 0.6% by weight), and the molecular weight is 5000 ~7500 polyethylene wax 2 parts, 7 # 4 parts of industrial white oil, 1 part of ethylene glycol, 0.6 parts of titanate coupling agent, 1.5 parts of zinc stearate, and 0.6 parts of dicumyl peroxide.

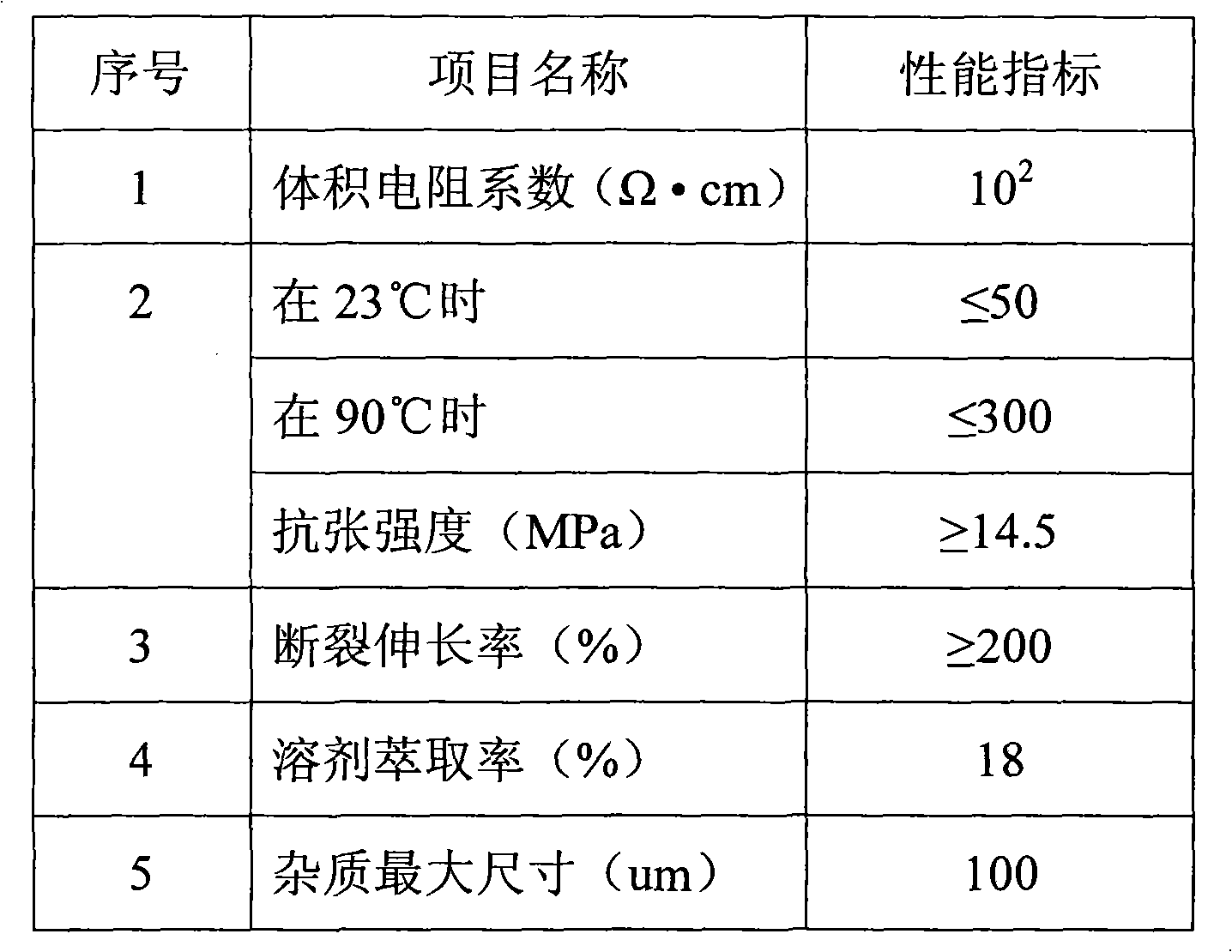

[0052] The semi-conductive shielding material for cross-linked polyethylene insulated cables prepared by adopting the above-mentioned embodiments of the present invention meets high-strength anti-stripping force applicable to high-voltage or ultra-high-voltage cross-linked insulated cables, has super-smooth shielding effect, and has a service life of 40 to 50 years. , the extrusion p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com