Backlight module press equipment and use method thereof

A technology of backlight module and pressing equipment, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of insufficient pressing, backlight module color light, insufficient strength, etc., to reduce labor costs, press The effect of tight and suppressing the generation of colored light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

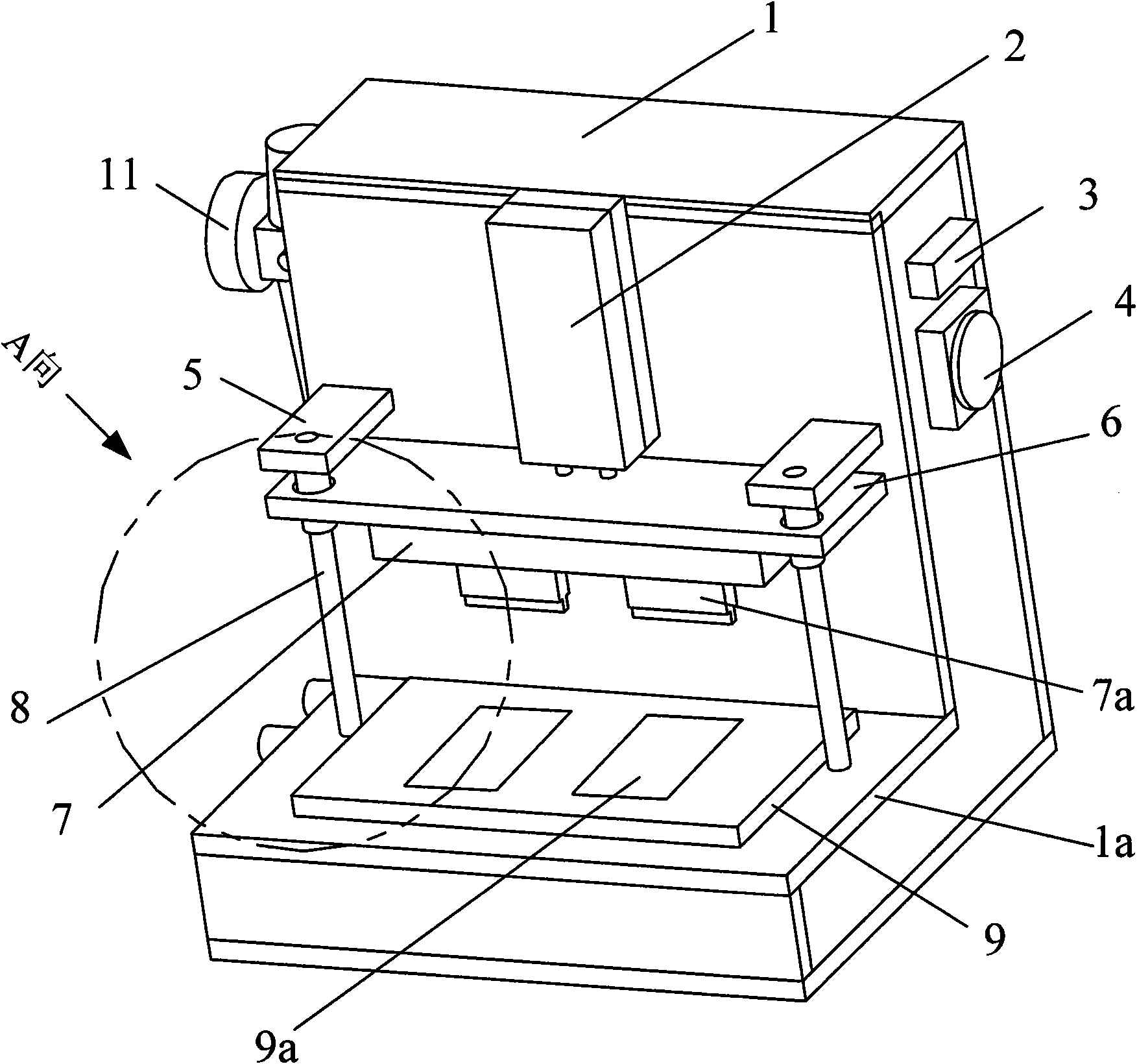

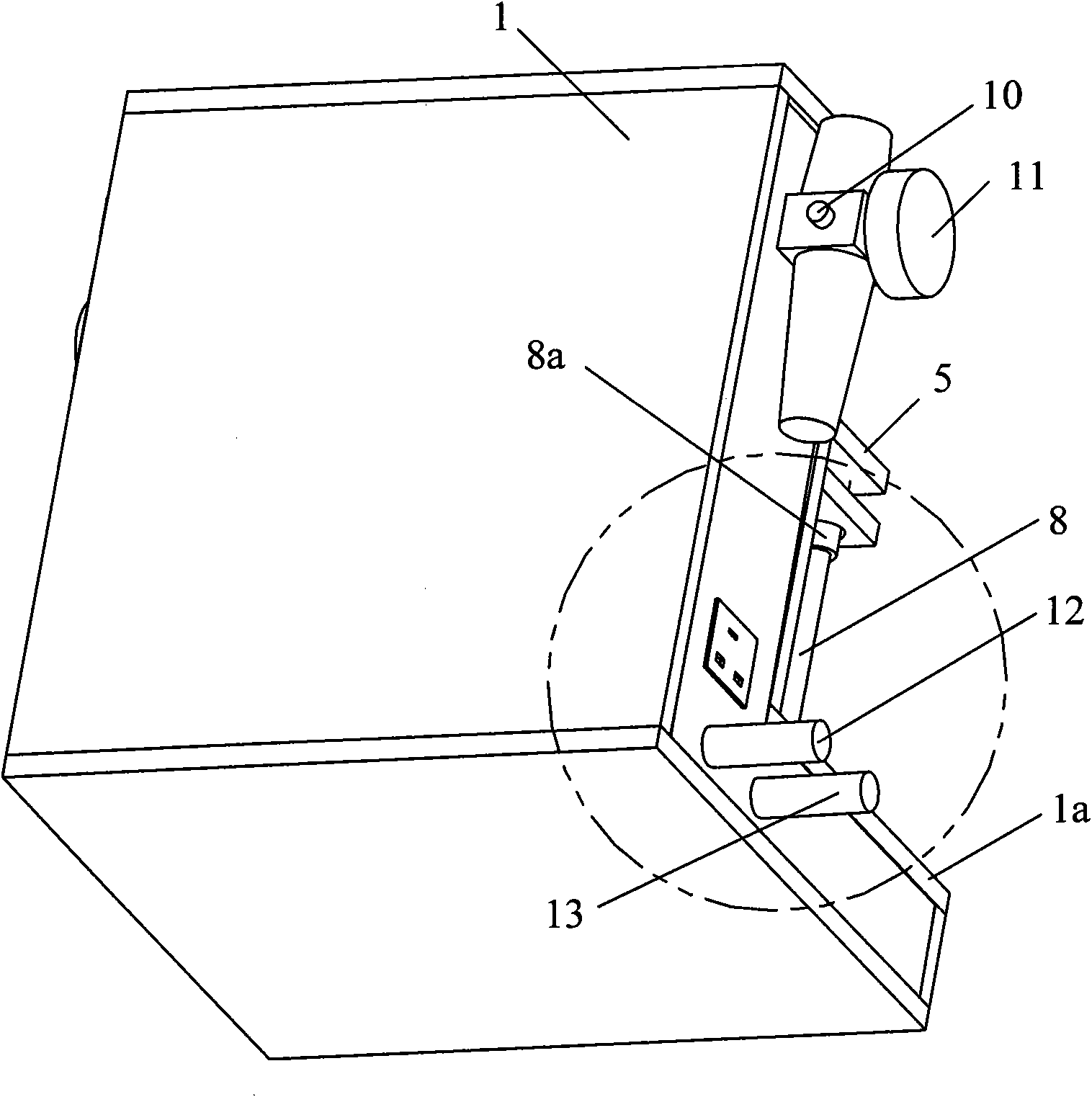

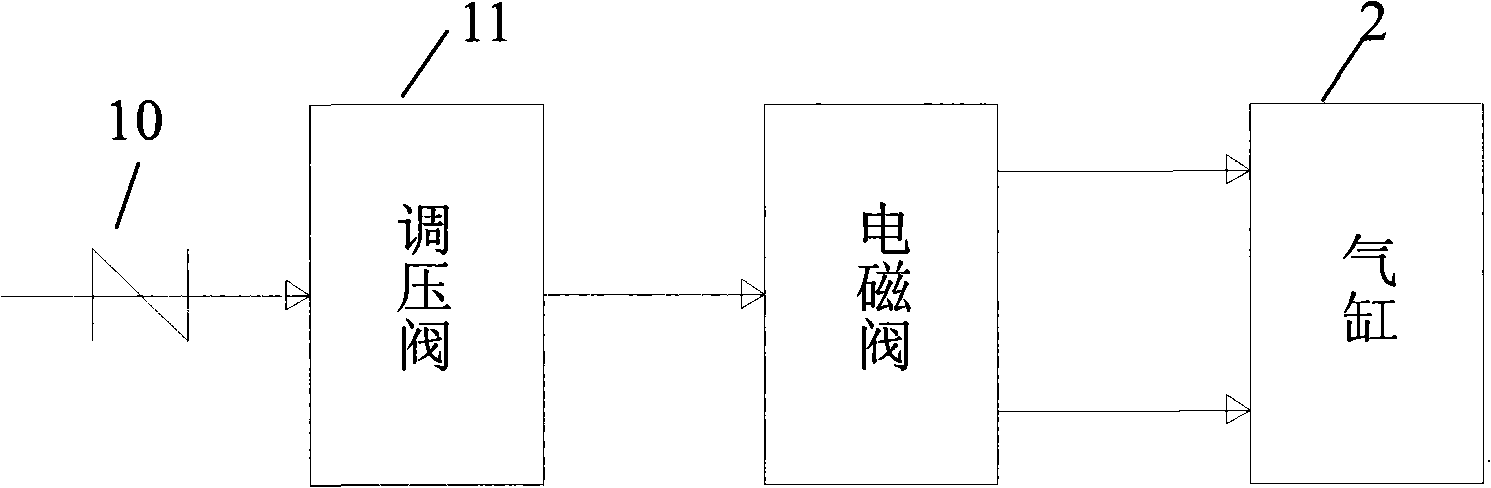

[0031] Such as Figure 1 to Figure 4 As shown, a backlight module press-fitting equipment includes: a box body 1 with a workbench 1a, an upper platen 6 that can run up and down, a lower platen 9 fixed above the workbench 1a, and two The guide rail 8 between the pressing plate 6 and the lower pressing plate 9, the lower end of the guide rail 8 is fixed on the workbench 1a, and the upper end passes through the upper pressing plate 6 and is fixed on the box body 1 through a guide rail fixing plate 5 to prevent the upper pressing plate from 6 slides out from guide rail 8 when running upwards. The connection hole between the upper platen 6 and the guide rail 8 is provided with a connection hole, and the upper end of the guide rail 8 passes through the connection hole and is fixed on the box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com