Production technology of high-strength electrode paste

A production process and airtight paste technology, which is applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve problems such as unstable product quality, poor thermal shock resistance, and low formula precision, so as to reduce production and operation costs and improve Effect of mechanical strength and strict screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The production process of the present invention has strict requirements on the selection of its raw materials. After testing, the proportioning is adjusted to the following raw materials and steps to make it. The weight proportioning of each raw material is:

[0021] (1) 36 parts of anthracite, (2) 27 parts of anode butt,

[0022] (3) 18 parts of metallurgical coke, (4) 6 parts of artificial graphite,

[0023] (5) 20 parts of coal tar pitch;

[0024] The steps are:

[0025] A. Selection of raw materials: The above-mentioned raw materials (1) to (5) are selected to make their characteristic indicators meet the following requirements: the anthracite after fine washing is calcined in an electric calciner at 2000 ℃, so that the ash content is ≤6 %, volatile matter 2 / m, true density ≥ 1.90g / cm3,

[0026] The residual anodes are first cleaned of surface impurities, and the soft residual anodes are selected for crushing.

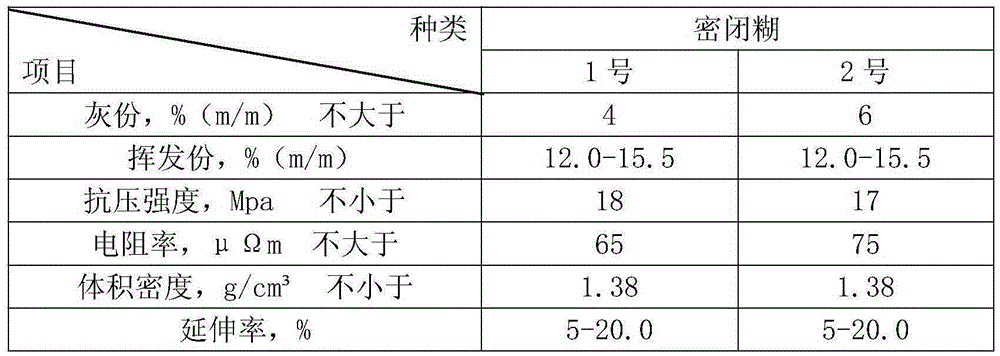

[0027] The physical and chemical indicators of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com