Hub for rolled wrap

a technology of rolled wrap and hub, which is applied in the field of rolled wrap hub, can solve the problems of unfavorable packaging, unfavorable packaging, and uneasy for users to tense stretch, and achieve the effects of convenient operation, smooth and firmly wrapping the article, and certain degree of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

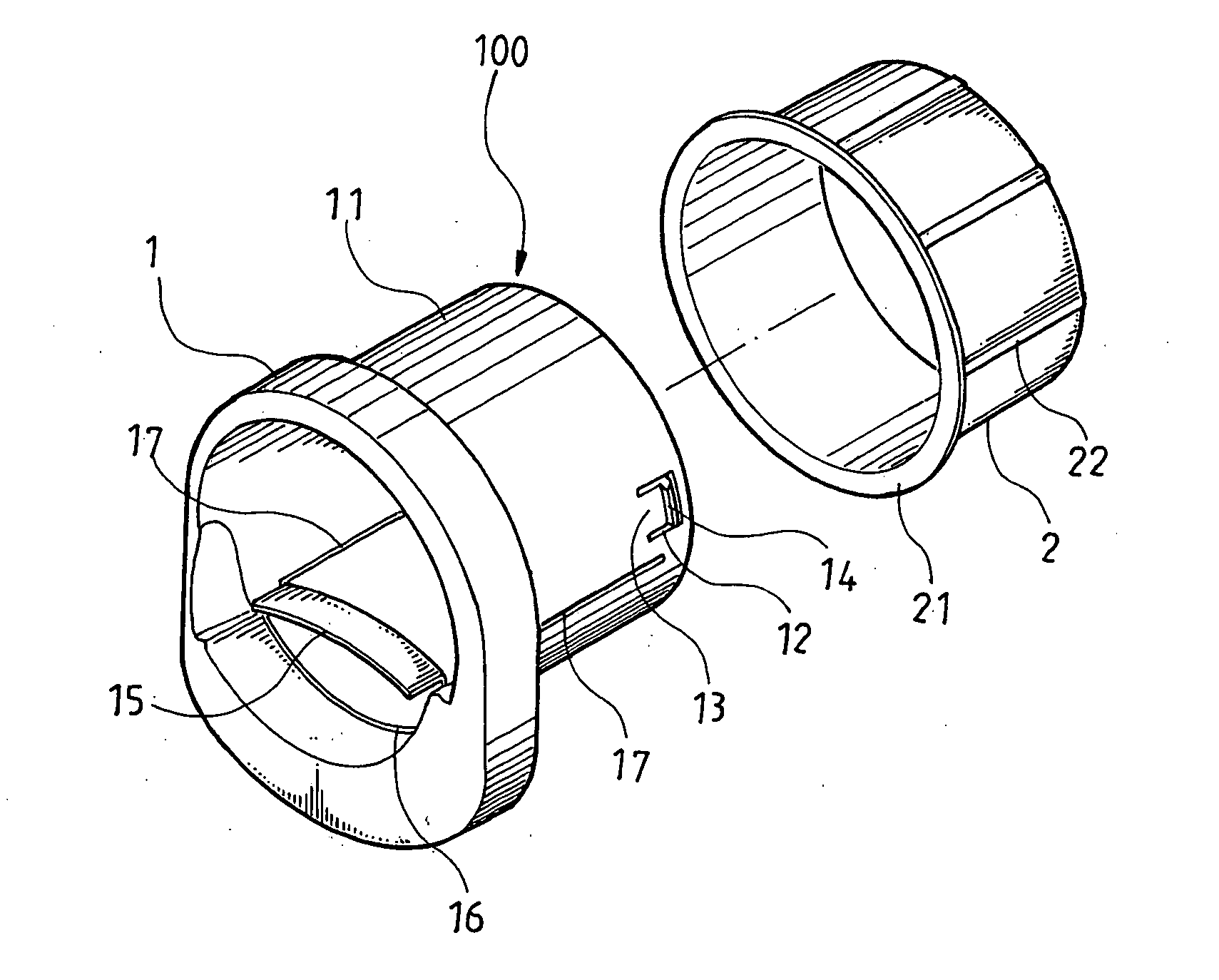

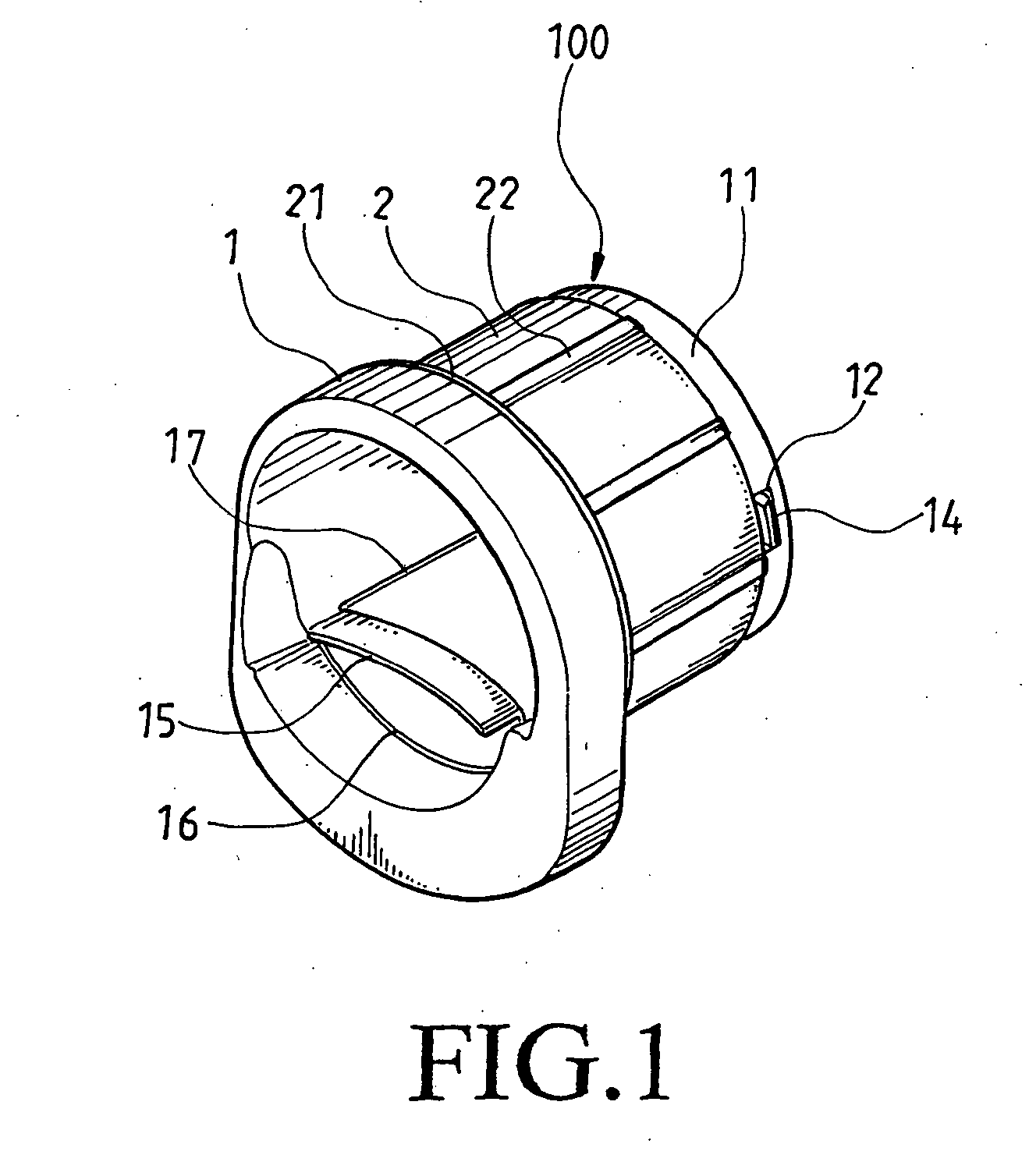

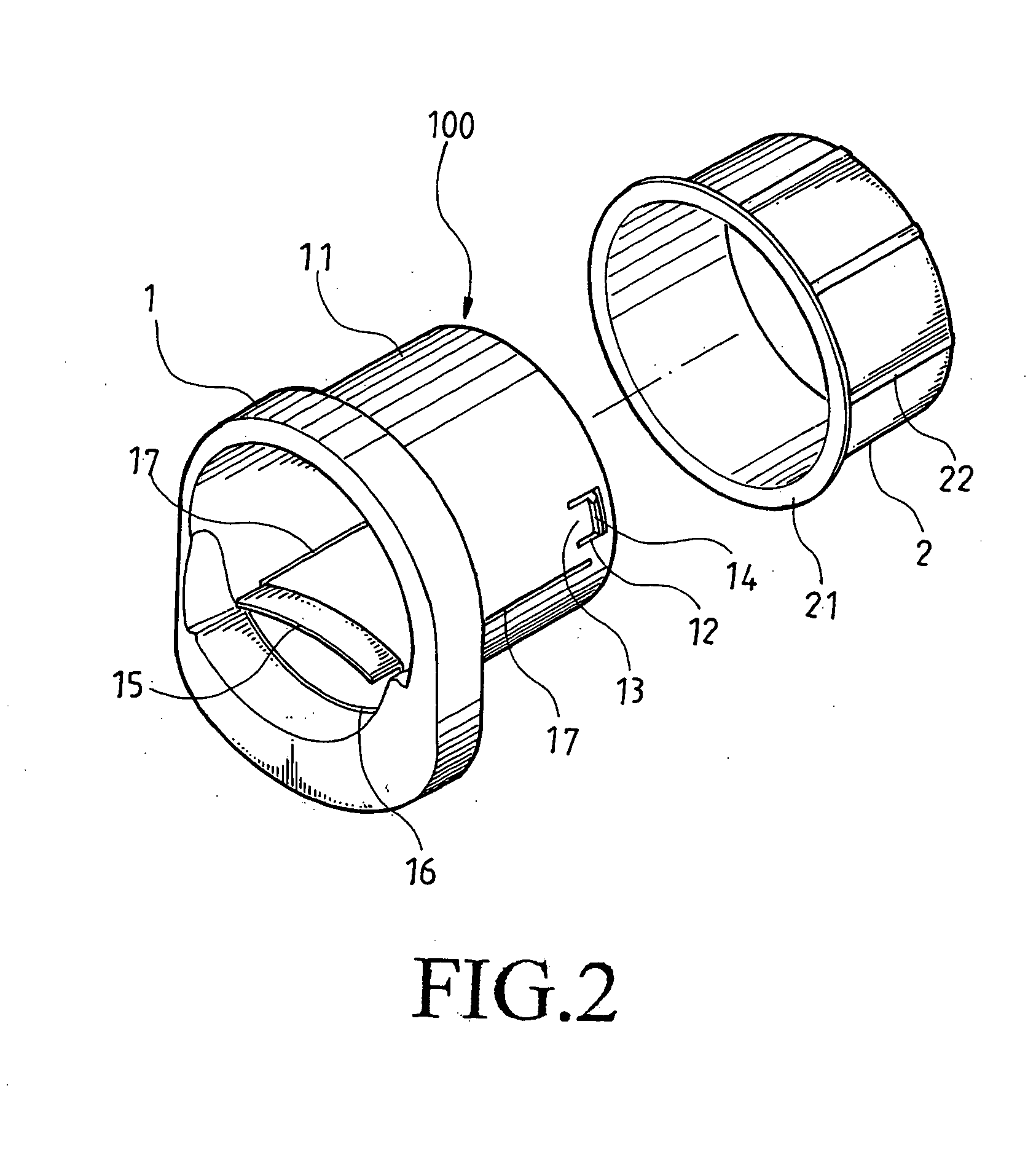

[0013] Please refer to FIGS. 1 and 2 that are assembled and exploded perspective views, respectively, of a hub for rolled wrap 100 according to an embodiment of the present invention, and to FIG. 3 that is a sectioned side view of the present invention. For the purpose of concision, the hub for rolled wrap 100 shall also be briefly referred to as the hub 100 throughout the specification. As shown, the hub 100 mainly includes a generally ring-shaped base 1 having a sleeve portion 11 axially extended from a rear side of the base 1 by a predetermined length, and a collar 2 having an inner diameter slightly larger than an outer diameter of the sleeve portion 11 of the base 1 for rotatably mounting around the sleeve portion 11.

[0014] The sleeve portion 11 of the base 1 is provided at two diametrically opposite sides near a rear end thereof with two axially extended U-shaped grooves 12 to form two elastic tabs 13. Free ends of the elastic tabs 13 are formed into two triangular ribs to fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com